Homogenizer Tray

A technology of coating machines and trays, which is applied in coatings and devices for coating liquid on the surface, can solve problems such as damage to the coating table, insufficient suction at the vacuum suction port, and poor uniformity of the photoresist film. Avoid damage, avoid the effect of insufficient suction or clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

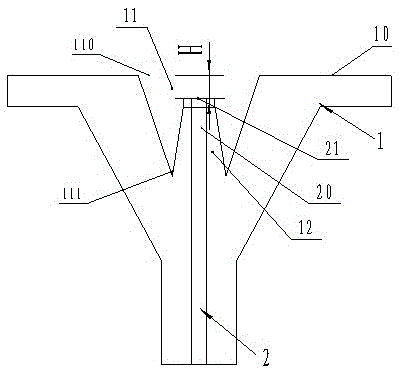

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0015] see figure 2 and image 3 , the embodiment of the present invention includes:

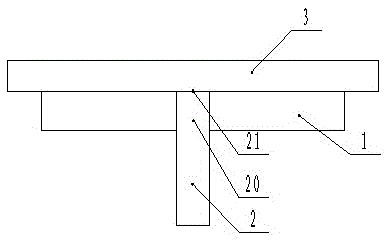

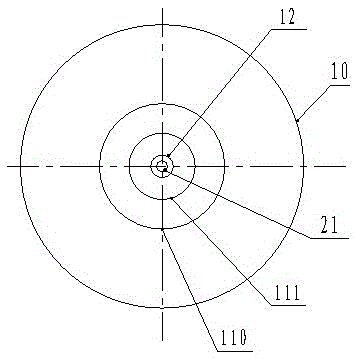

[0016] A tray for a glue homogenizer, comprising: a silicon wafer support platform 1 and a vacuum suction tube 2, the top of the silicon wafer support platform 1 has a silicon wafer bearing plane 10, and the silicon wafer bearing plane 10 is a circular On the horizontal plane, a glue storage tank 11 is provided inwardly along the center of the circle of the silicon wafer bearing plane 10, and a conical boss 12 is provided in the middle of the glue storage tank 11; the vacuum suction piece tube 2 comprises: The upper end 20 and the vacuum suction sheet openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com