A multi-scan drive axis movable polygonal mirror optical path direct writing device

A drive shaft and polygon mirror technology, applied in the field of direct writing exposure, can solve the problems of inability to produce super large plates, inaccurate focusing and positioning, air leakage of vacuum suction cups, etc., and achieve the effects of reducing deformation, high precision, and preventing edge warping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1: Vacuum suction cup

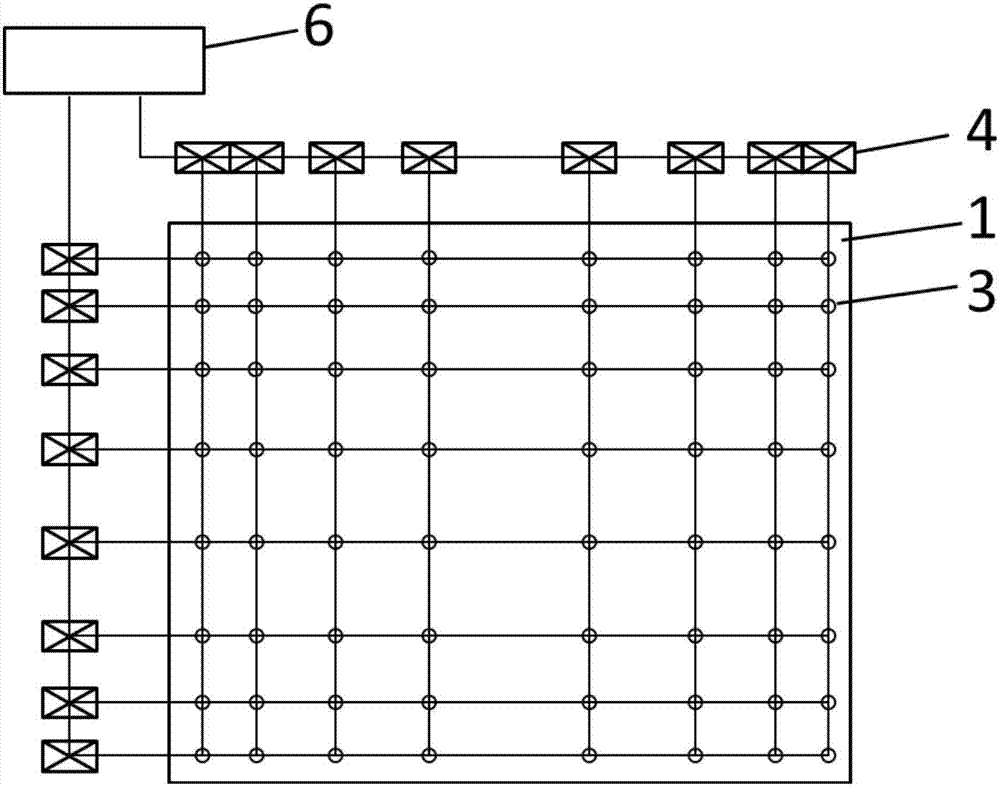

[0080] The vacuum chuck structure of the present invention is as Figure 1-2 shown.

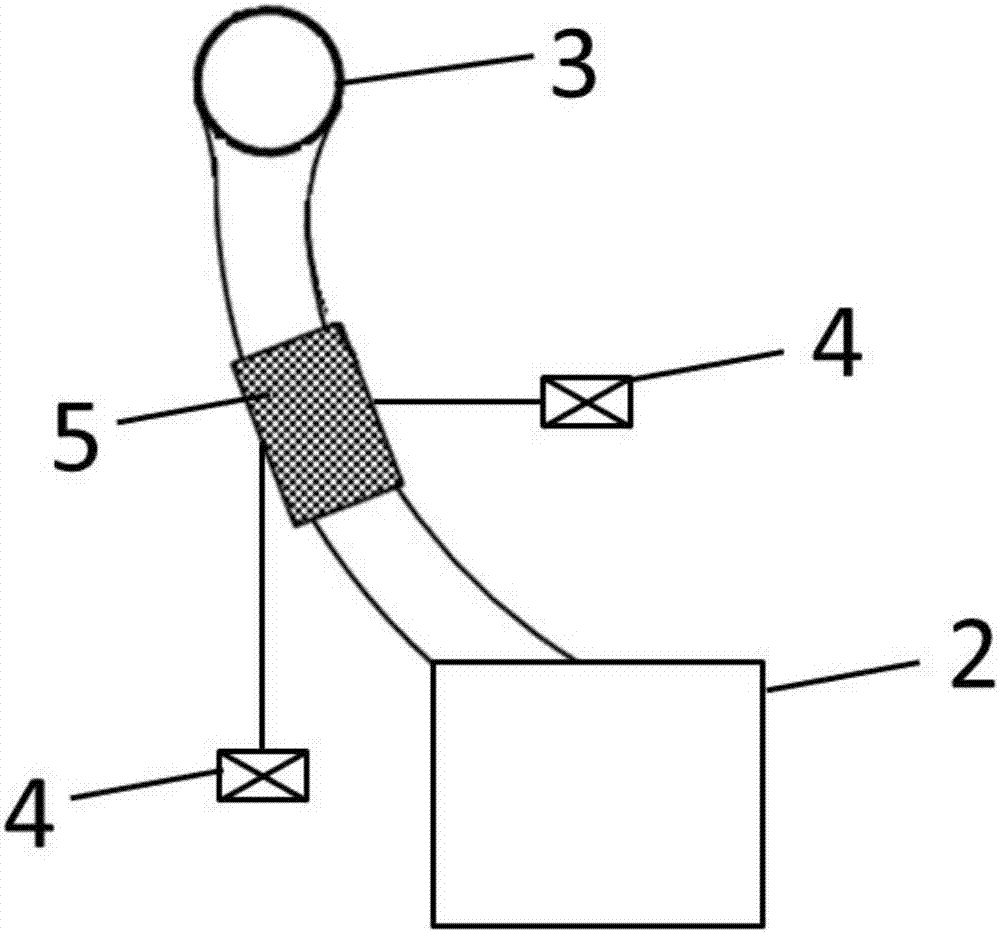

[0081] The vacuum suction cup of the present invention includes a suction cup main body 1 and a vacuum generating device 2; a certain number of air holes 3 are distributed on the suction cup main body 1 in the form of rows and columns, each row of air holes 3 corresponds to a relay 4, and each column of air holes also corresponds to a relay ; Between each air hole 3 and the vacuum generating device 2, an air hole switch 5 is connected; the air hole switch 5 is connected with the relay in the row of the air hole and the relay in the column of the air hole at the same time.

[0082] Each relay is connected with the general control device 6 . The air hole switch is located on the vacuum pipeline connected between the air hole and the vacuum generating device. The air hole switch may be an electromagnetic switch. The air holes may be evenly distributed o...

Embodiment 2

[0084] Example 2: Vacuum suction cup

[0085] The vacuum chuck of the present embodiment, in embodiment 1 such as Figure 1-2 A modified version of the vacuum cup shown.

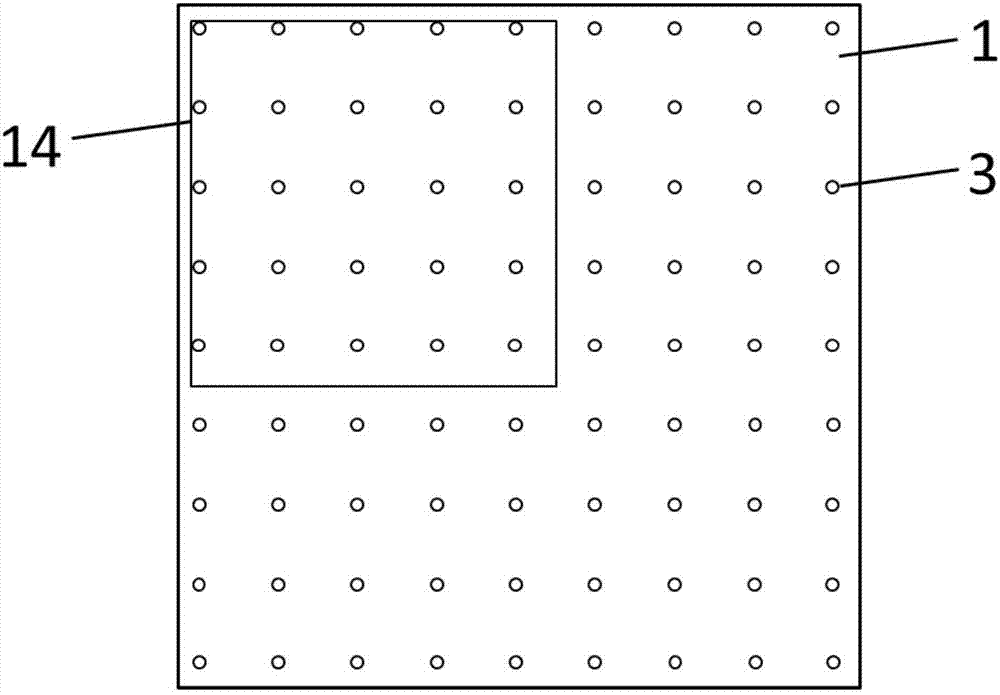

[0086] The air holes 3 on the main body 1 of the suction cup are distributed sparsely in the middle and densely around.

[0087] In traditional vacuum chucks, the air holes are generally evenly distributed. When producing a small PCB, it is possible that after the substrate 14 is placed on the main body of the suction cup, a certain edge of the substrate is located far away from the air holes on both sides (such as image 3 As shown), the edge part will be lifted due to the lack of vacuum suction, which will affect the production. After adopting the distribution form of the present invention, which is sparse in the middle and dense around, as Figure 4-5 As shown, when a small substrate is placed on the vacuum chuck, choose to place the substrate close to the edge of the suction cup body. Move to the nea...

Embodiment 3

[0091]Embodiment 3: Direct writing device with movable polygonal mirror and optical path with dual scanning drive shafts

[0092] A direct writing device with a movable polygonal mirror optical path with dual scanning drive shafts containing two moving components is taken as an example for illustration.

[0093] Such as Figure 6-7 Shown is a double-scan drive shaft movable polygonal mirror optical path direct writing device containing a vacuum chuck of the present invention.

[0094] The dual-scan drive shaft movable polygonal mirror optical path direct writing device includes a base 7, a polygonal mirror optical path 8, a stepping drive shaft 9, a plurality of moving components, a vacuum chuck 10, a connecting plate 15, and a camera 16; each moving component includes a scanning Drive the Y-axis 12 and a lifting drive Z-axis 13; the vacuum chuck 10 is located above the moving assembly.

[0095] The polygonal mirror optical path 8 is connected with the stepping drive shaft 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com