Polyamide and production method and application thereof

A polyamide and product technology, applied in the field of low-cost polyamide and its production, can solve the problem of high raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

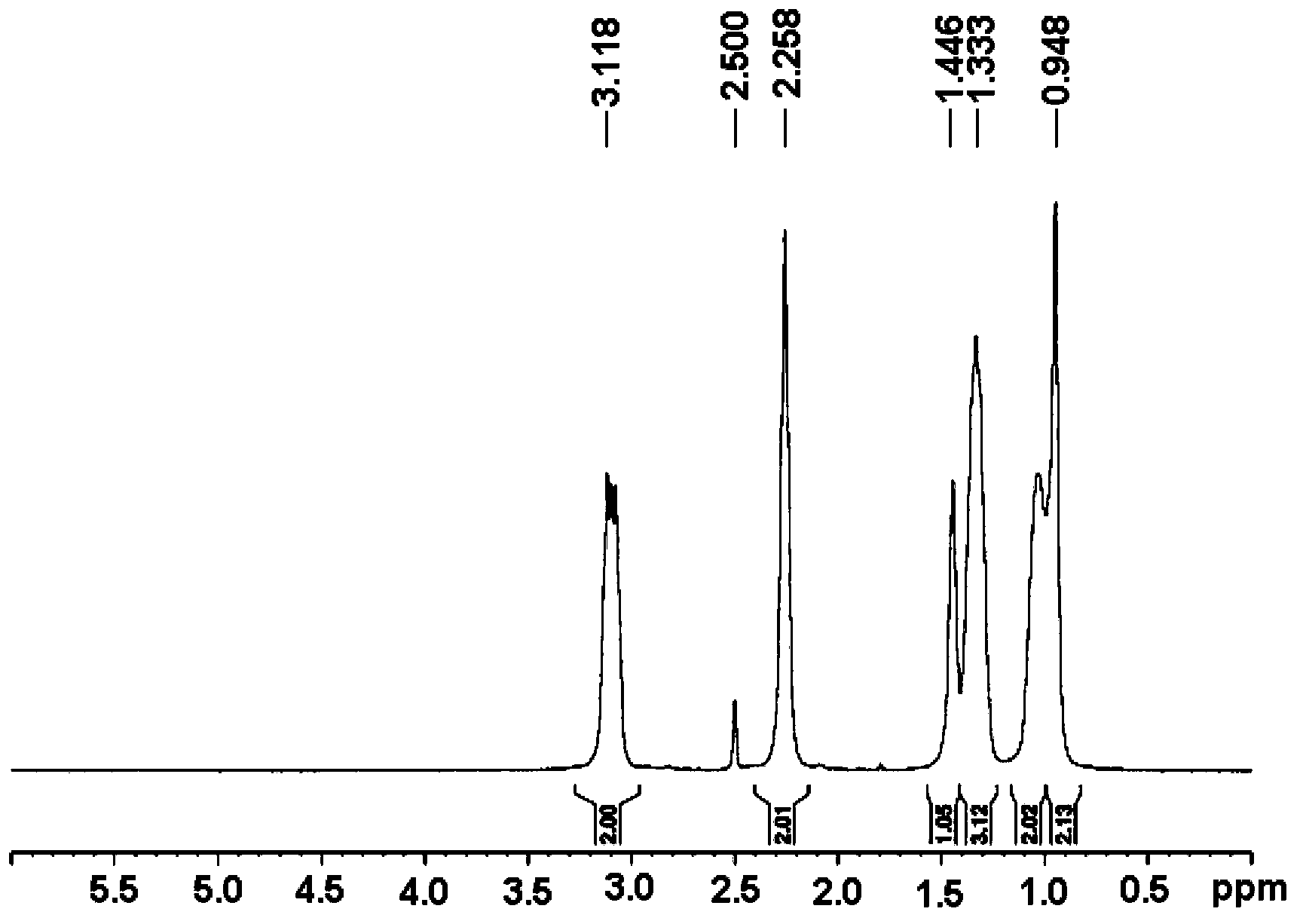

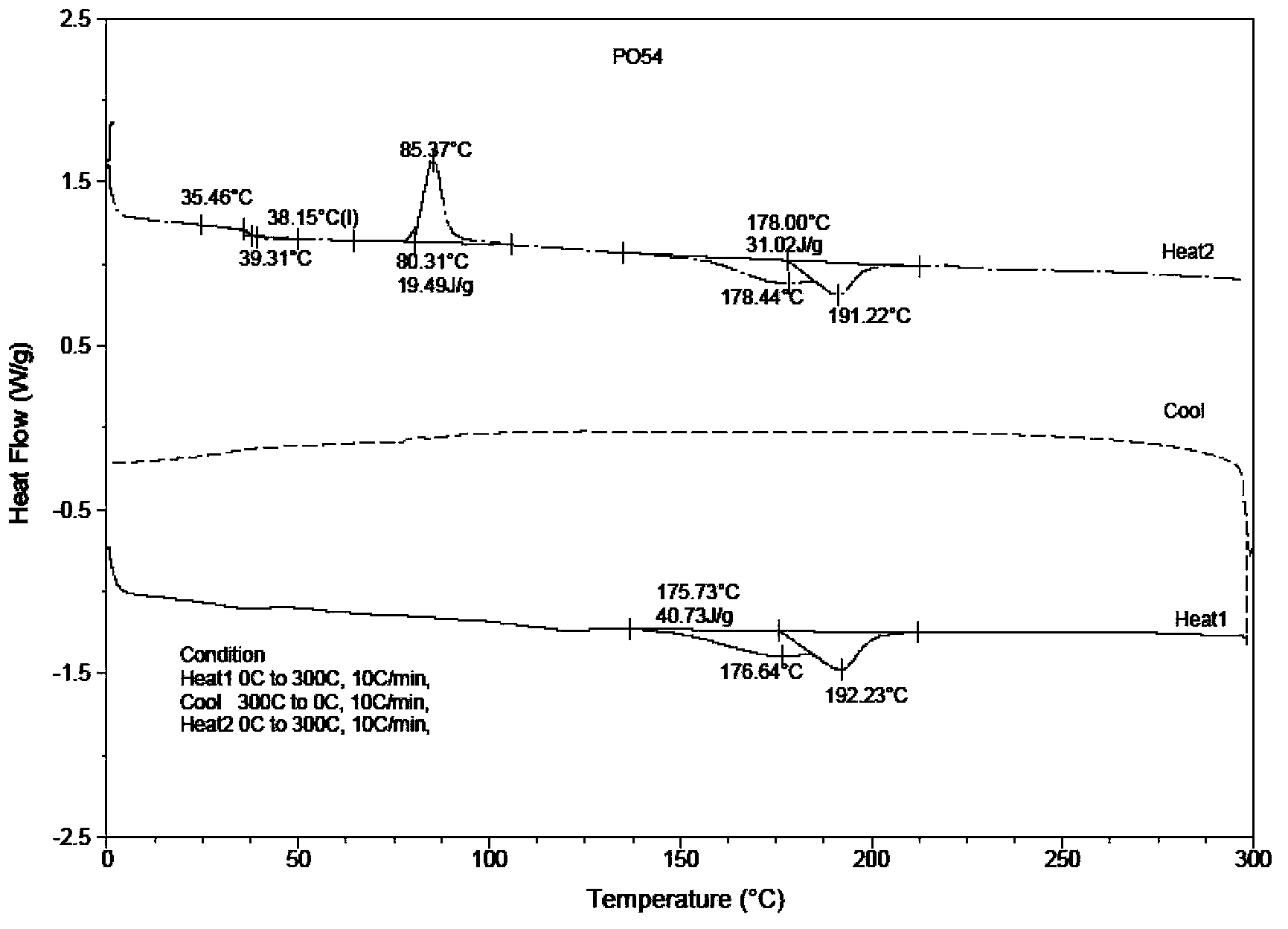

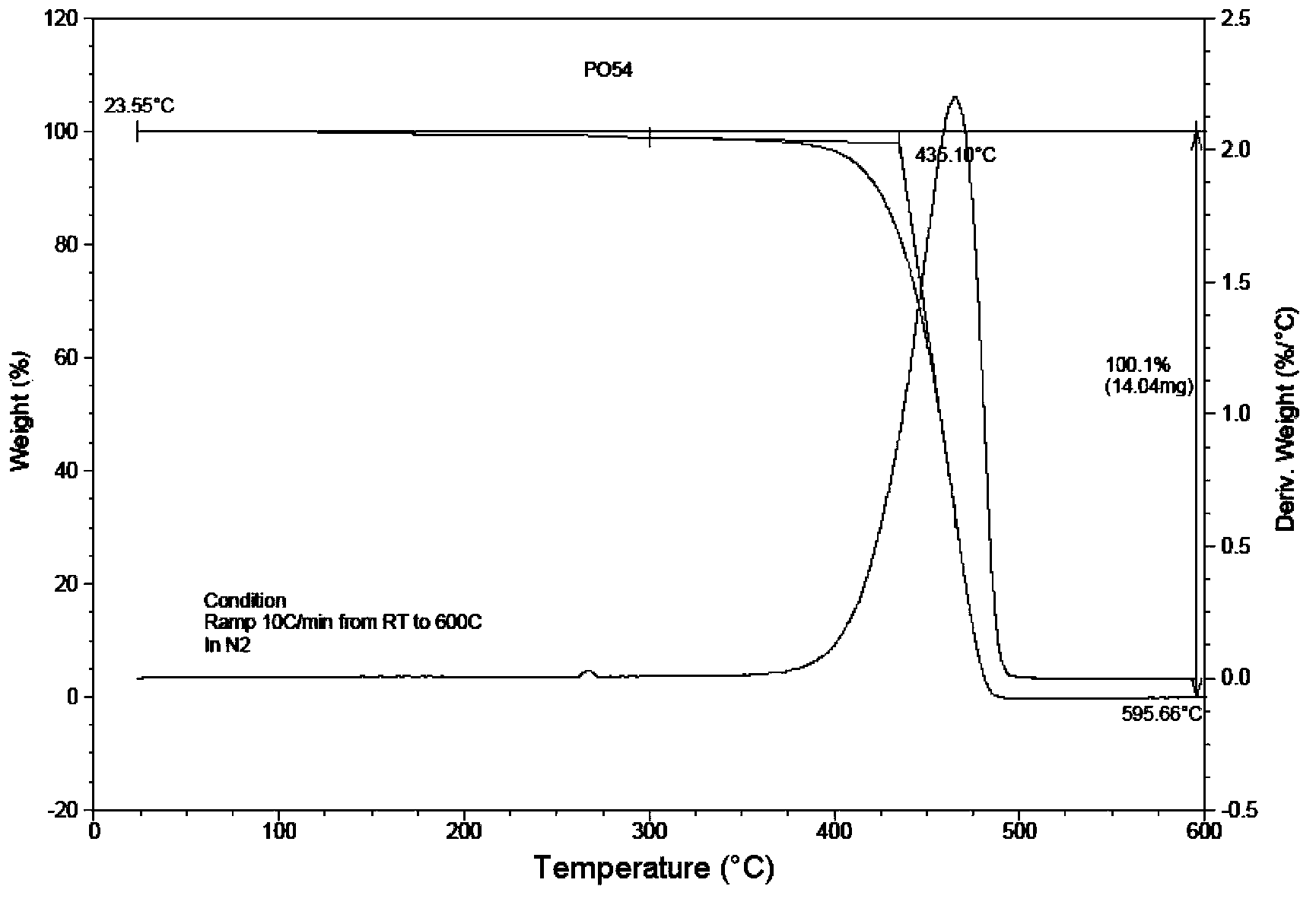

[0119] The preparation of embodiment 1, nylon 5612

[0120] Under a nitrogen atmosphere, add 30kg of pure water to the reactor, then add 10.56kg (0.103mol) of pentamethylenediamine (containing organic carbon from renewable sources that meet the ASTM D6866 standard), stir, and add 7.55kg (0.051mol) of adipic acid and 11.89kg (0.051mol) of dodecanedibasic acid, and then add 3g of antioxidant H10 to prepare a nylon salt solution.

[0121] Under a nitrogen environment, the temperature of the oil bath was raised to 230°C. After the pressure in the polymerization kettle rose to 1.73Mpa, the exhaust gas was started. When the temperature in the kettle reached 265°C, the vacuum was pumped to -0.06Mpa, and the vacuum degree was maintained for 20 minutes to obtain Nylon 5612.

[0122] Fill the polymerization kettle with nitrogen to a pressure of 0.5Mpa, start melting and discharging, and use a pelletizer to granulate. After vacuum drying at 80°C for 8 hours, various performance tests w...

Embodiment 2

[0126] Embodiment 2, the preparation of nylon 5612

[0127] In addition to adjusting the addition of pentamethylenediamine to 9.46kg (0.092mol), the addition of adipic acid to 1.35kg (0.009mol) and the addition of dodecanedibasic acid to 19.18kg (0.083mol) in Example 1, The same operation as in Example 1 was carried out. According to embodiment 1, using 1 Characterized by H-NMR, it was confirmed that the target product was obtained. Various performance tests were carried out on the obtained polyamide resin, and the results are shown in Table 1.

Embodiment 3

[0128] Embodiment 3, the preparation of nylon 5612

[0129] In addition to adjusting the addition of pentamethylenediamine to 11.94kg (0.117mol), the addition of adipic acid to 15.36kg (0.105mol) and the addition of dodecanedioic acid to 2.69kg (0.011mol) in Example 1, The same operation as in Example 1 was carried out. According to embodiment 1, using 1 Characterized by H-NMR, it was confirmed that the target product was obtained. Various performance tests were carried out on the obtained polyamide resin, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com