Pavement hardening system for rural road

A road and rural technology, applied in the field of road hardening pavement system, can solve the problems of low efficiency, rising material cost, high construction cost, etc., and achieve the effect of simple and fast operation, convenient erection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

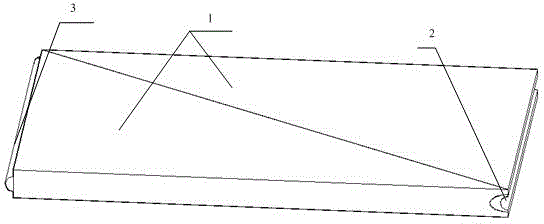

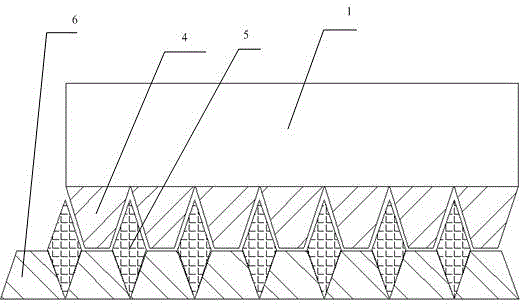

[0022] Such as Figure 1-Figure 3 shown.

[0023] The rural road hardened pavement system includes a plurality of prefabricated roadbed connectors 5 that are embedded and riveted with the roadbed 6. A plurality of prefabricated roadbed structures 1 are arranged above the prefabricated roadbed connectors along the direction of road advancement. Each prefabricated pavement structure 1 is provided with side protrusions 3 on the front side, and each prefabricated pavement structure 1 is provided with side grooves 2 on the rear side, and the side protrusions 3 of the prefabricated pavement structure 1 are inserted into the adjacent prefabricated pavement structures 1. In the side groove 2; the lower side of the prefabricated pavement structure is provided with a lower protrusion 5, the cross-section of the prefabricated roadbed connector is a quadrilateral prism, and the surface of the roadbed forms a pre-embedded recess whose axis extends along the road width direction and whose c...

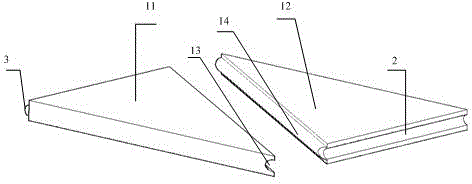

Embodiment 2

[0027] In this embodiment, on the basis of Embodiment 1, in order to facilitate transportation and installation, reduce the weight of a single mounting part, and at the same time, in order to prevent the prefabricated pavement structure from moving after the force is applied to both sides of the road, the prefabricated pavement structure in the present invention The body includes a first split block 11 and a second split block 12, the first split block 11 and the second split block 12 are right-angled triangles of the same size, wherein the side protrusion 3 is arranged on the first split block 11 on the right-angled side A, the side groove is arranged on the right-angled side B of the first split block 11, the hypotenuse of the first split block 11 is provided with a split connecting groove 13, and the oblique side of the second split block 12 The side is provided with split connection protrusions 14, and the split connection protrusions 14 are inserted into the split connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com