Grease backflow device of annular isolation-type respirator

An isolated, lubricating oil technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of reducing the effect of separating lubricating oil of respirator, increasing lubricating oil discharge and fuel consumption, etc., to reduce lubricating oil consumption, The effect of improving the recovery rate and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

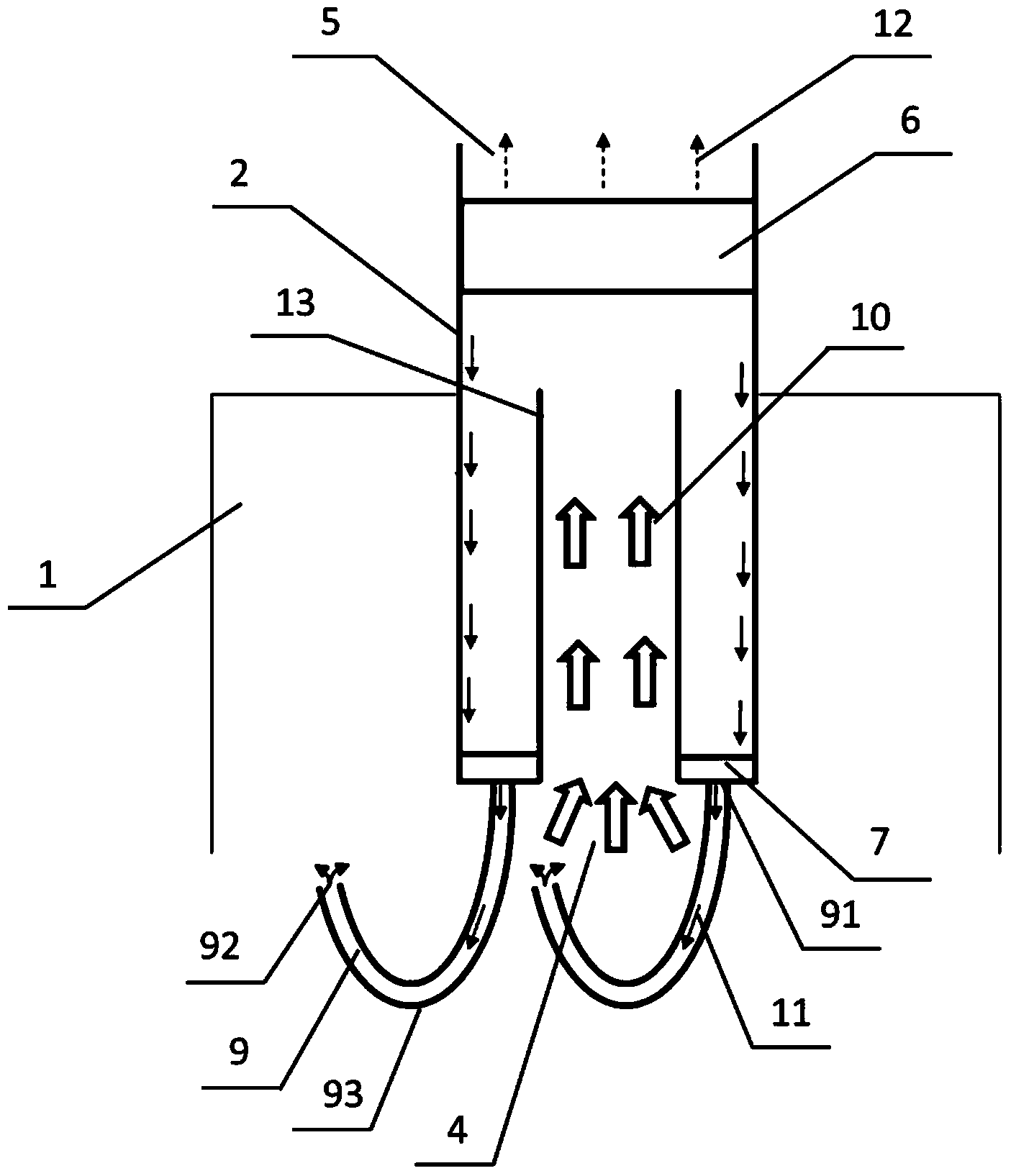

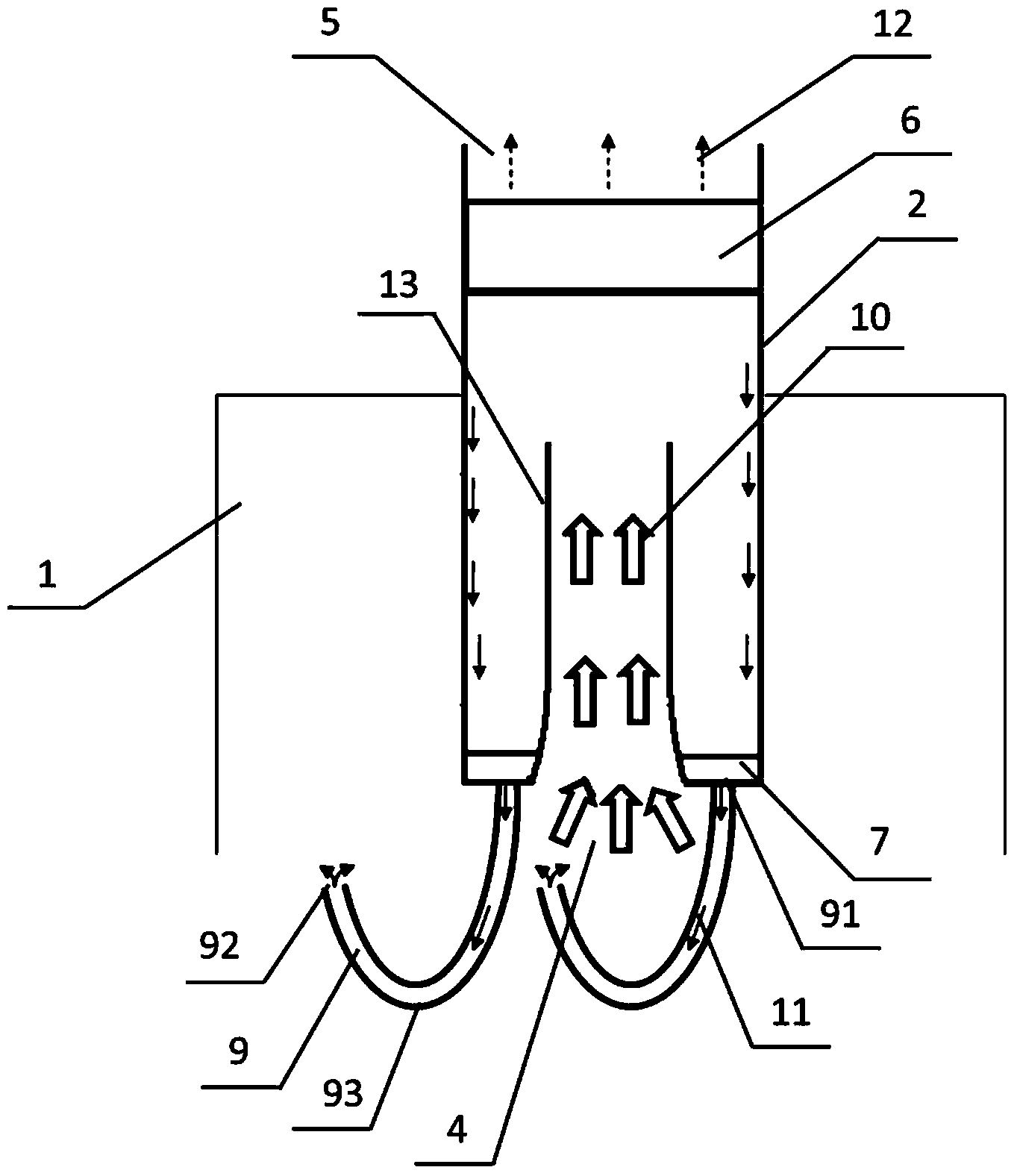

[0023] Such as figure 1 As shown, a preferred embodiment of the present invention provides an annular isolated respirator lubricating oil return device, and its structure specifically includes an oil-gas separation part 6, a lubricating oil recovery part 7, a lubricating oil return part 9 and an airflow guide part 13. The oil-gas separation component 6 is set at the air outlet 5 on the top of the respirator 2 . The gas guiding part 13 is cylindrical, one end communicates with the air inlet 4 arranged at the bottom of the respirator, and the other end opens toward the oil-gas separating part 6 . In another embodiment of the present invention, as figure 2 As shown, the gas guide member 13 is set such that the opening at one end is larger than the opening at the other end, and the end with the larger opening communicates with the air inlet. This shape of the gas guide member 13 is more conducive to the entry of oil mist with lubricating oil.

[0024] Such as figure 1 and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com