Circulation Filtration Fuel Filter

A fuel filter and circulating filtration technology, which is applied to machines/engines, liquid fuel feeders, engine components, etc., can solve problems such as high material labor costs, unfavorable energy conservation and environmental protection, and increased oil flow resistance, etc. The effect of reducing the amount of impurities, reducing the resistance and pressure loss, and reducing the dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

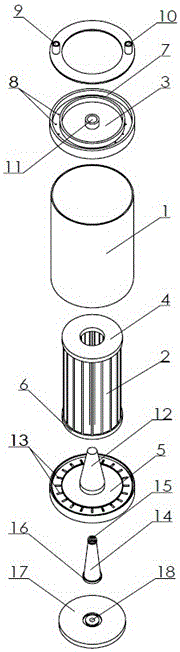

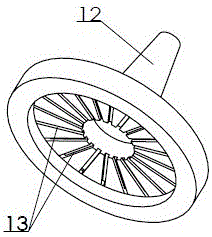

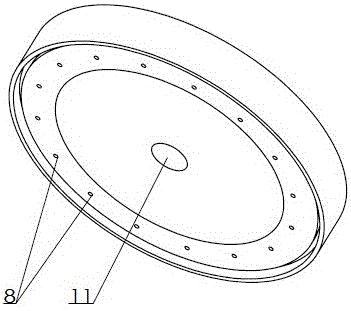

[0018] Examples of the present invention Figures 1 to 4 As shown, the circulating filter fuel filter is provided with a housing 1 and a main filter element 2, the housing and the main filter element are both hollow cylinders as a whole, the main filter element is a star-shaped folded filter screen, and the main filter element is arranged in the housing and Coaxial with the housing, the two ends of the main filter element are connected with upper and lower sealing rings, and the two ends of the housing are connected with upper and lower covers, the upper sealing cover 3 is pressed on the upper sealing ring 4, the lower sealing cover 5 is pressed on the lower sealing ring 6, and the upper sealing cover 5 is pressed on the lower sealing ring 6. The sealing cover is provided with an annular flow channel 7, and the oil material inlet hole 8 connecting the space between the shell and the main filter element is arranged in the annular flow channel. The oil material inlet holes are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com