Pipe pushing jack mud control system

A technology of control system and pipe jacking machine, applied in pipeline system, mechanical equipment, pipeline laying and maintenance, etc., can solve the problems of scarcity of operators, high mechanical failure rate, slow construction progress, etc. The effect of serious blockage and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

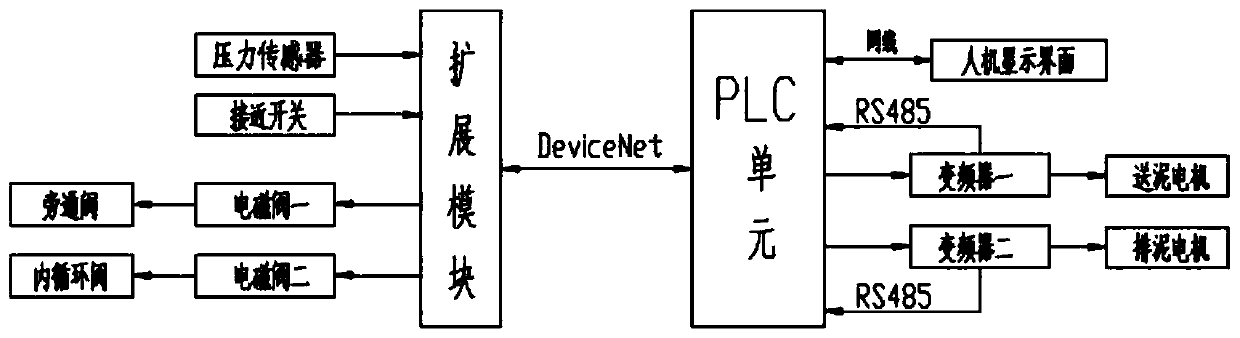

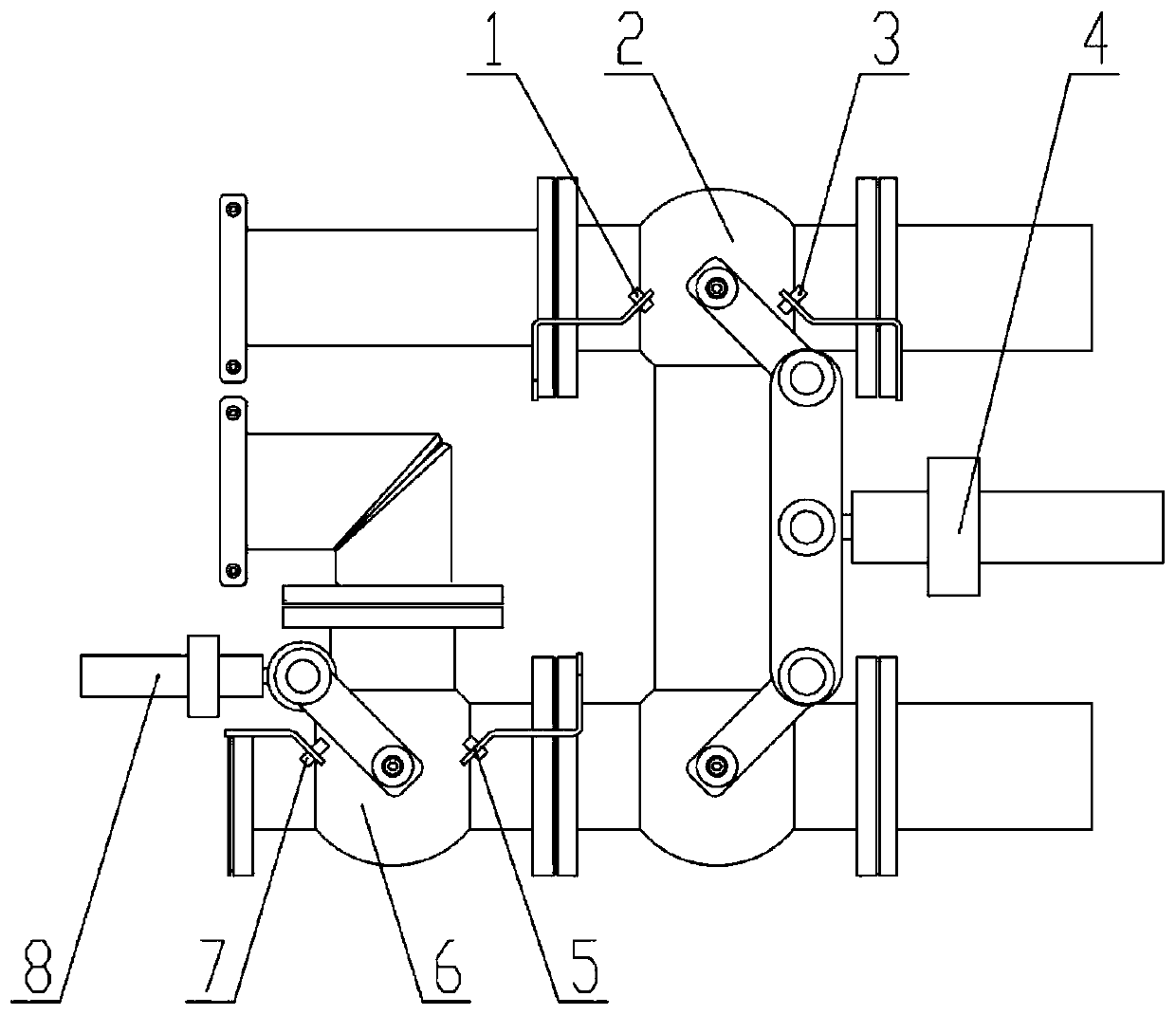

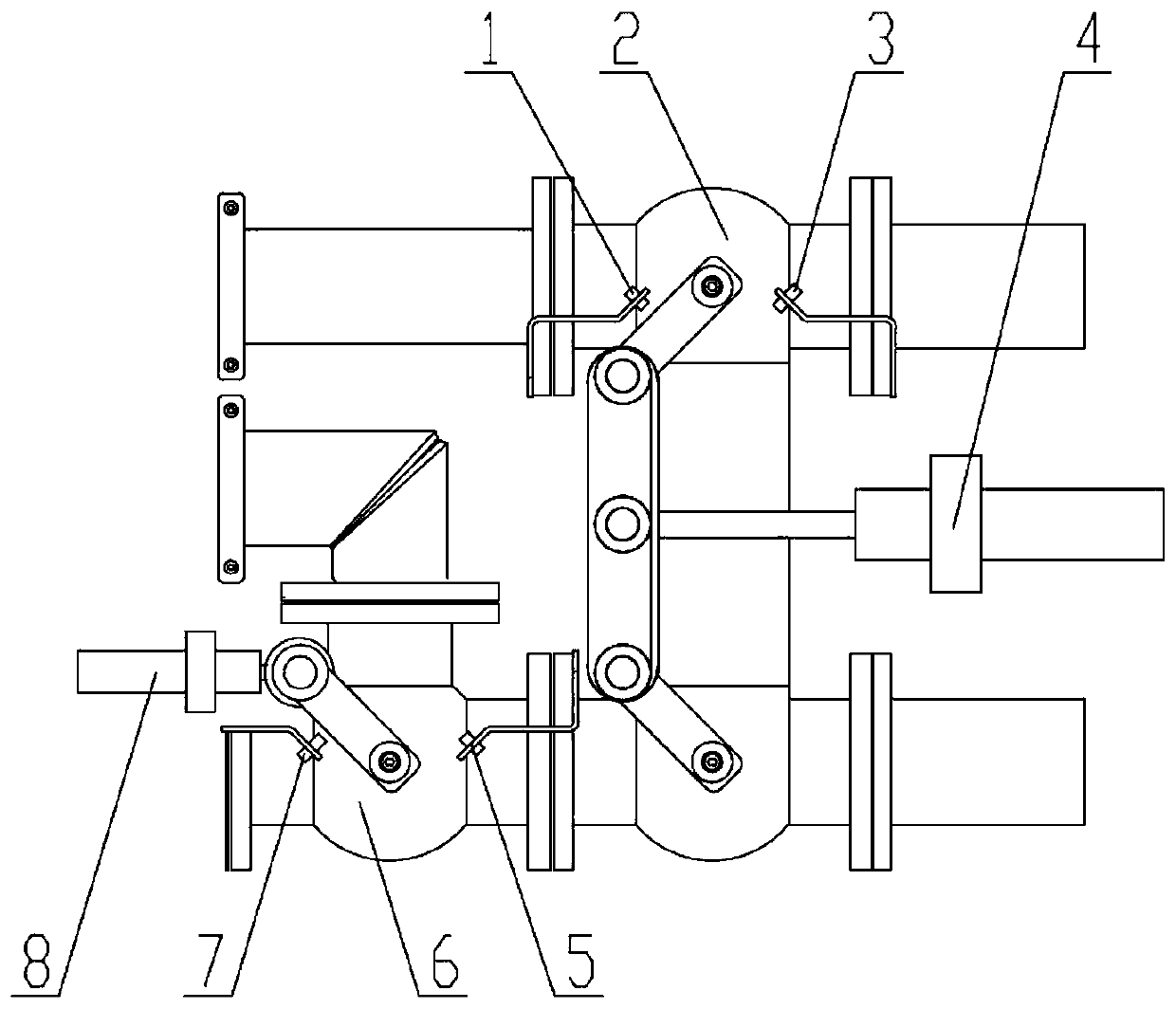

[0023] combine figure 1 with figure 2 As shown, the control module includes PLC unit and expansion module. The PLC unit and the man-machine display interface are installed in the ground operation platform; the PLC unit is used to control the mud feeding motor and the mud discharge motor, the man-machine display interface communicates with the PLC unit through the network cable, and the man-machine display interface is used to display the parameters of the sensor and the solenoid valve on-off status. The expansion module is installed in the internal control cabinet of the machine head. The expansion module is electrically connected with solenoid valve 1, solenoid valve 2, and multiple pressure sensors and proximity switches to collect corresponding signals; the expansion module communicates with the PLC u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com