Overturning device for overturning molten material and purging method

A turning device and melt technology, applied in chemical instruments and methods, fluid flow, transportation and packaging, etc., can solve the problems of time consumption, cost, waste, and inability to carry out valuable production, so as to reduce thermal impact and shorten stay Duration, avoiding delayed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

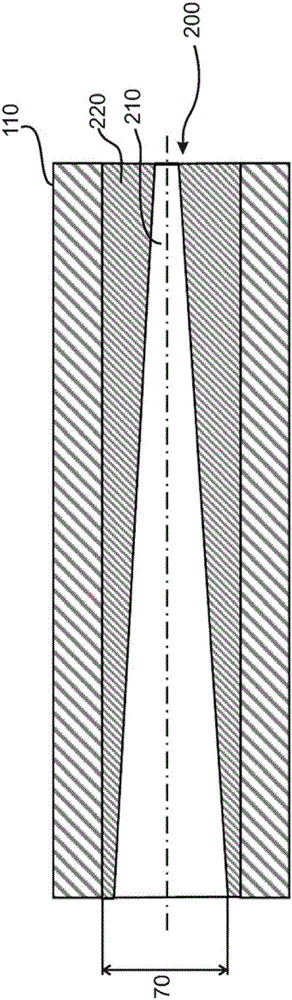

[0050] exist figure 1 The melt channel 110 with flow direction from left to right is shown in , as it appears during the flushing process. A free flow cross section 70 is provided within the melt channel 110 , through which the melt 200 flows. A distinction is made here between old melt material 220 and new melt material 210 . It can be clearly seen here that the elongated course through the melt channel 110 forms a ramp-shaped or conical configuration between the old melt material 220 and the new melt material 210 during the flushing process. The cone moves to the right in course during the purge time until eventually most of the old melt material 220 has been discharged and can be further processed with active production.

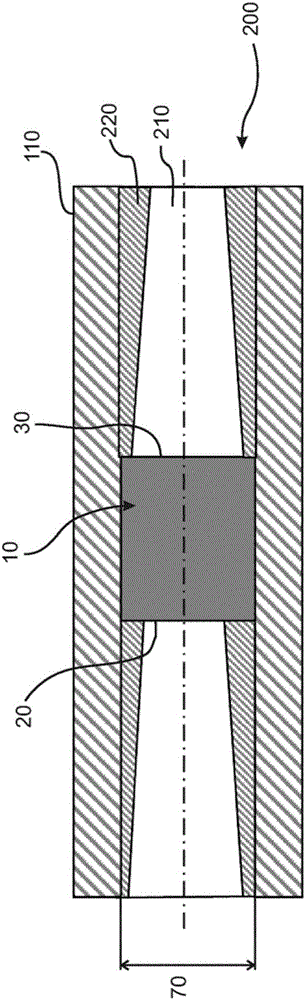

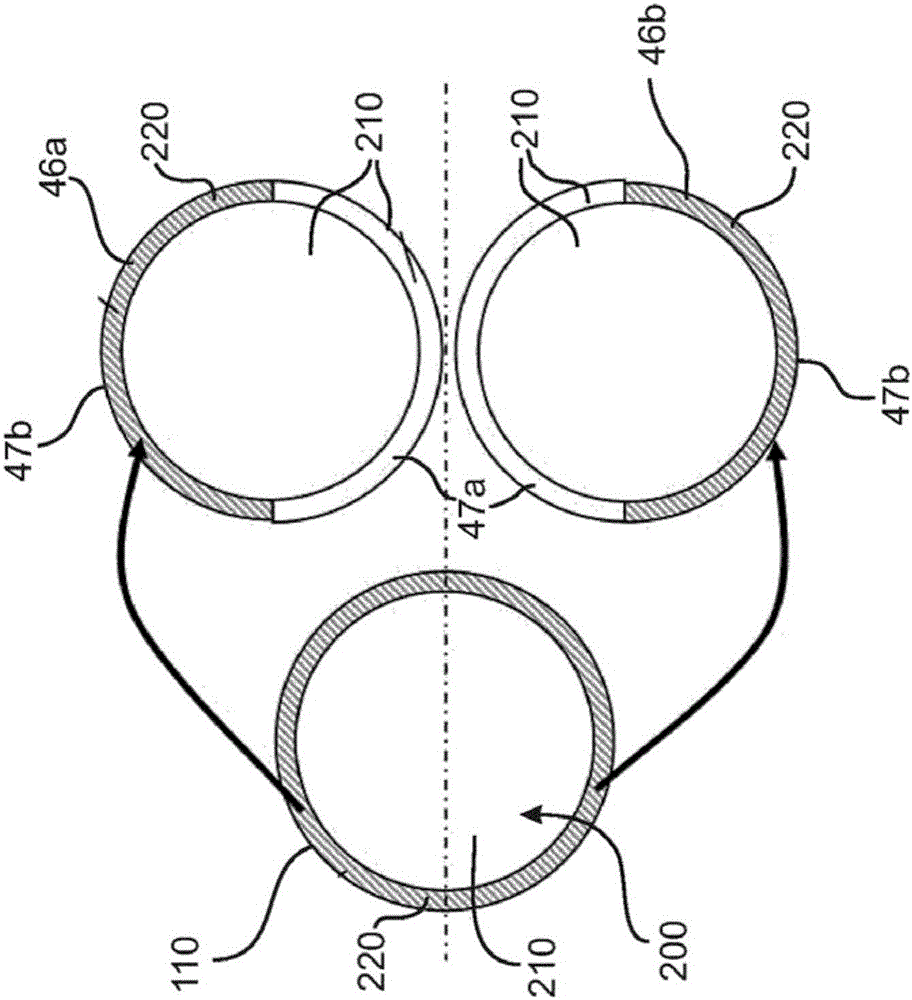

[0051] exist figure 2 The mode of operation of the turning device 10 according to the invention is shown in . Here, a transfer now takes place from the edge of the melt 200 to the center of the melt 200 and vice versa. Accordingly, material from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com