Modified limestone powder dry grinding and screening equipment

A limestone powder and screening equipment technology, applied in the field of limestone, can solve the problems of low material screening efficiency, blockage of filter mechanism, and reduced material screening efficiency, so as to improve the overall processing effect and avoid serious blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

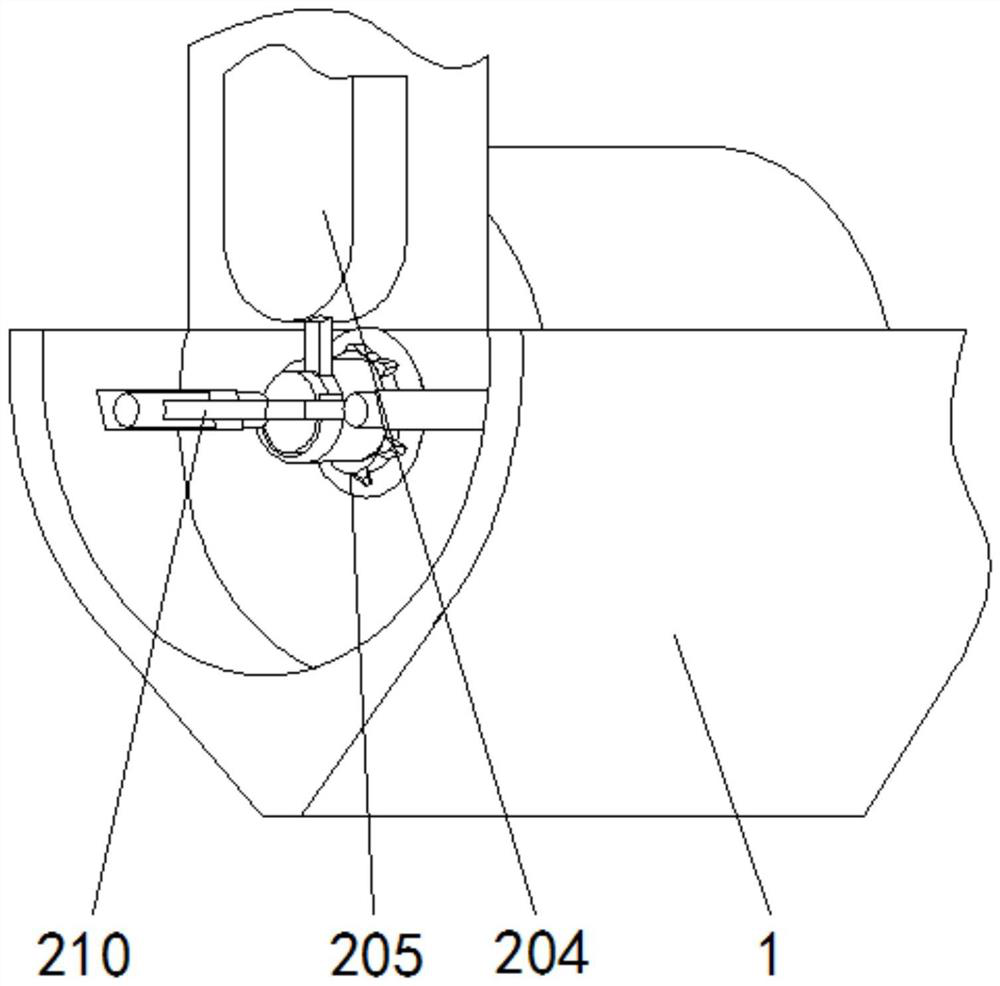

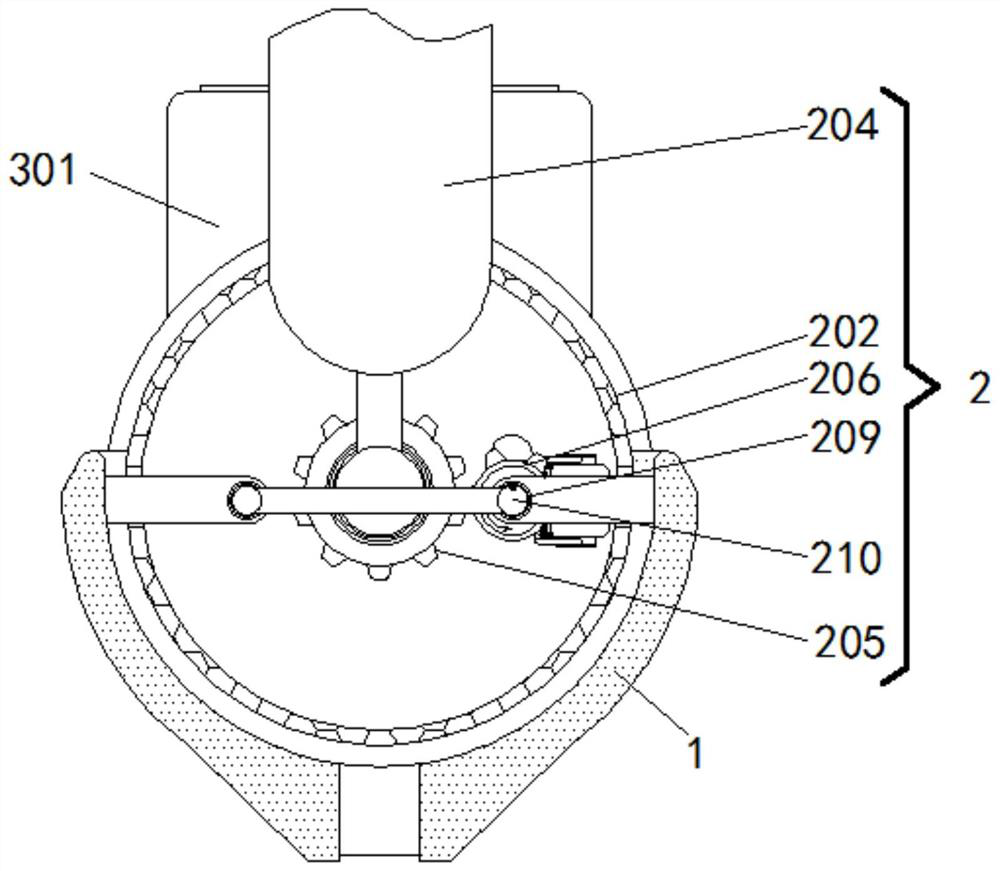

[0023] see figure 2 , image 3 and Figure 5 , a modified limestone powder dry grinding and screening equipment, including a base 1, the upper part of the base 1 is designed to be coated with an iron screen drum 202, and a trough is opened at the bottom, so as to facilitate the protection of the iron screen drum 202 When rotating, the limestone powder sieved inside can fully fall into the inner cavity of the base 1 and output along the trough. The upper end of the base 1 is movably connected with a dry grinding mechanism 2, which includes a shaft tube 201 The left and right sides of the shaft tube 201 are fixedly connected with guide plates corresponding to the grinding rollers 203, so that the limestone particles falling from the top of the iron screen cylinder 202 can be guided and dropped between the grinding rollers 203. In addition, the shaft tube 201 The inner cavity of the lower wall iron screen cylinder 202 is provided with a through groove, so as to introduce the e...

Embodiment 2

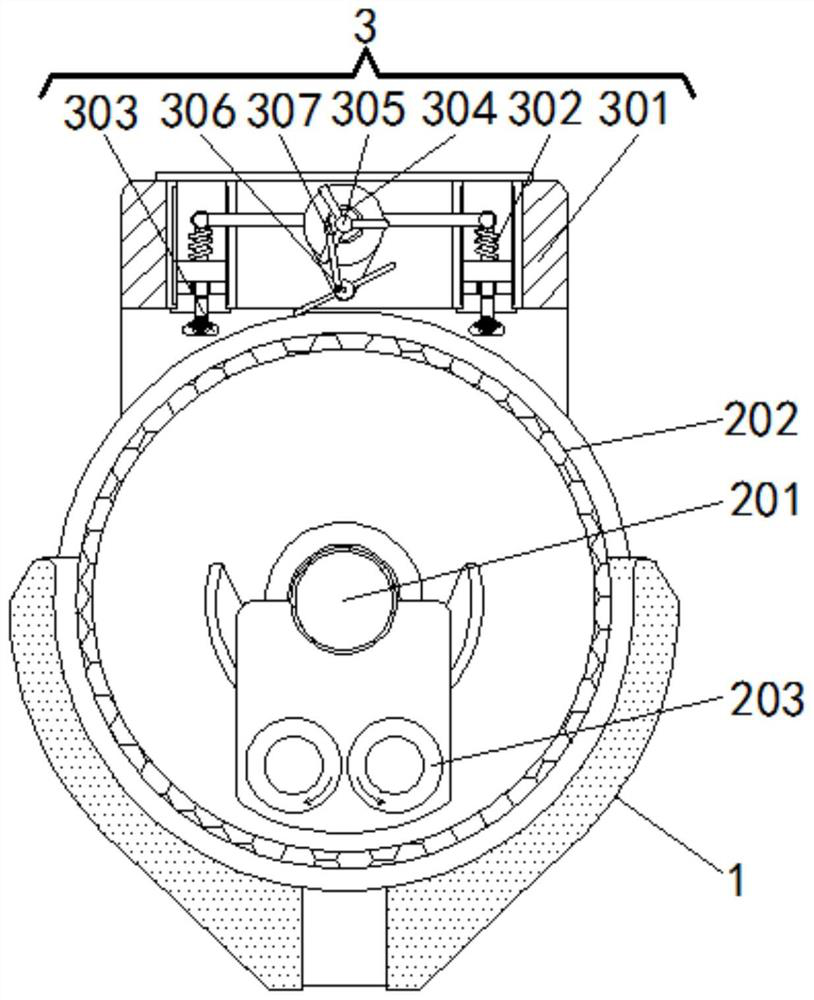

[0025] see Figure 3-Figure 4 , a modified limestone powder dry grinding and screening equipment, also includes a cleaning mechanism 3, the cleaning mechanism 3 is fixedly connected to the front side of the upper iron screen drum 202 of the base 1, and the cleaning mechanism 3 includes a receiving plate 301, which accepts The rear end of the plate 301 is slidably connected with a symmetrical electromagnetic elastic rod 302, and the lower end of the electromagnetic elastic rod 302 is movably connected with an abutment block 303, and the rotating end of the abutment block 303 is movably sleeved with a torsion rod extending to the electromagnetic elastic rod 302. Spring assembly, so that when the abutment block 303 is not driven to abut against the outer wall of the iron screen cylinder 202, it can be restrained by the torsion spring assembly to maintain balance, avoiding directly overlapping the surface of the iron screen cylinder 202 to affect its rotation, and the electromagnet...

Embodiment 3

[0027] see Figure 1-Figure 5, a modified limestone powder dry grinding and screening equipment, including a base 1, the upper part of the base 1 is designed to be coated with an iron screen drum 202, and a trough is opened at the bottom, so as to facilitate the protection of the iron screen drum 202 When rotating, the limestone powder sieved inside can fully fall into the inner cavity of the base 1 and output along the trough. The upper end of the base 1 is movably connected with a dry grinding mechanism 2, which includes a shaft tube 201 The left and right sides of the shaft tube 201 are fixedly connected with guide plates corresponding to the grinding rollers 203, so that the limestone particles falling from the top of the iron screen cylinder 202 can be guided and dropped between the grinding rollers 203. In addition, the shaft tube 201 The inner cavity of the lower wall iron screen cylinder 202 is provided with a through groove, so as to introduce the external limestone p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com