Open circulating water, gas and liquid orthogonal diaphragm plate type air cooler

An open cycle and air cooler technology, applied in the field of cooling towers, can solve the problems of complex structure, short service life, and large maintenance of air coolers, and achieve the effect of simple and practical structure, low cost, safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

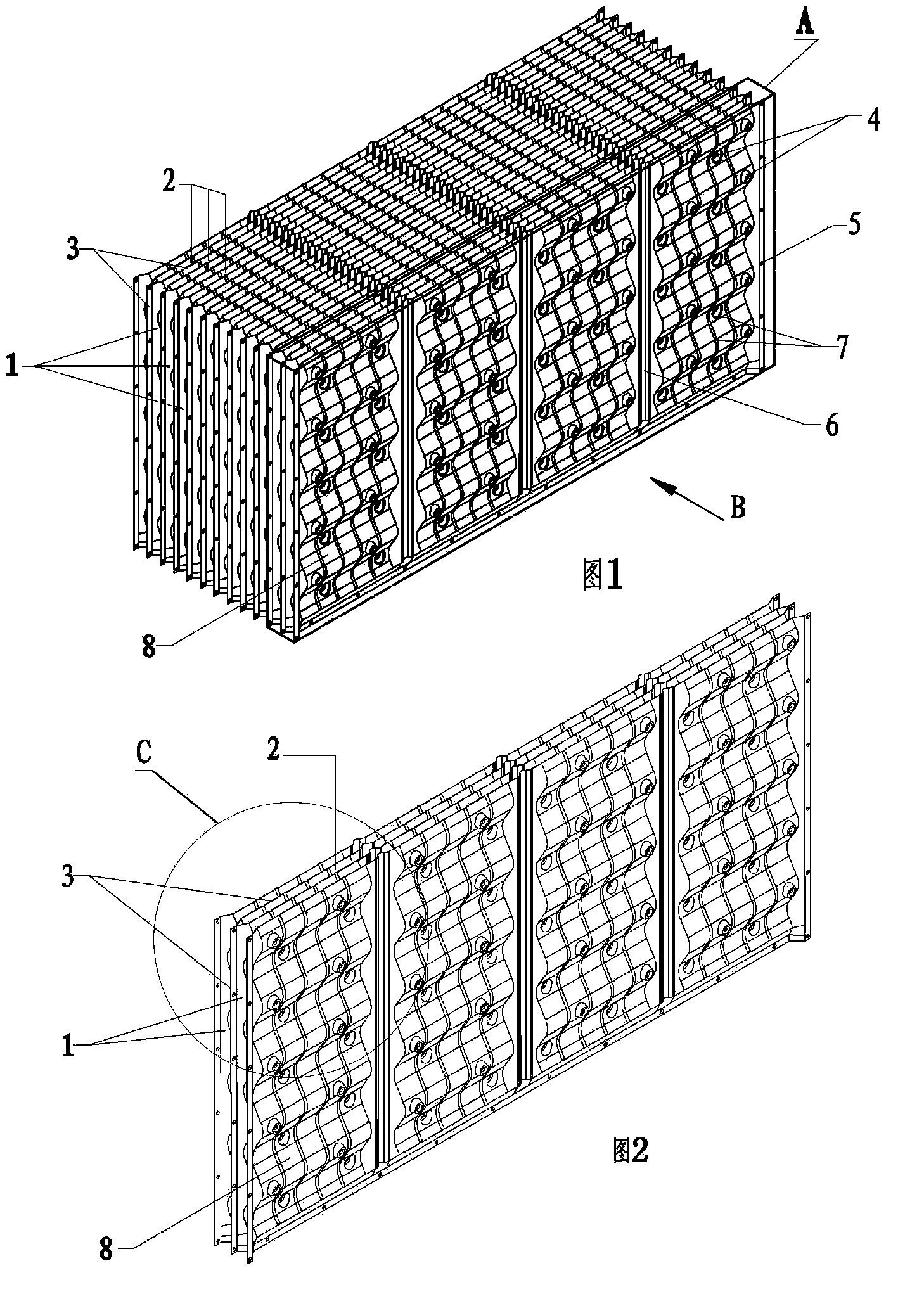

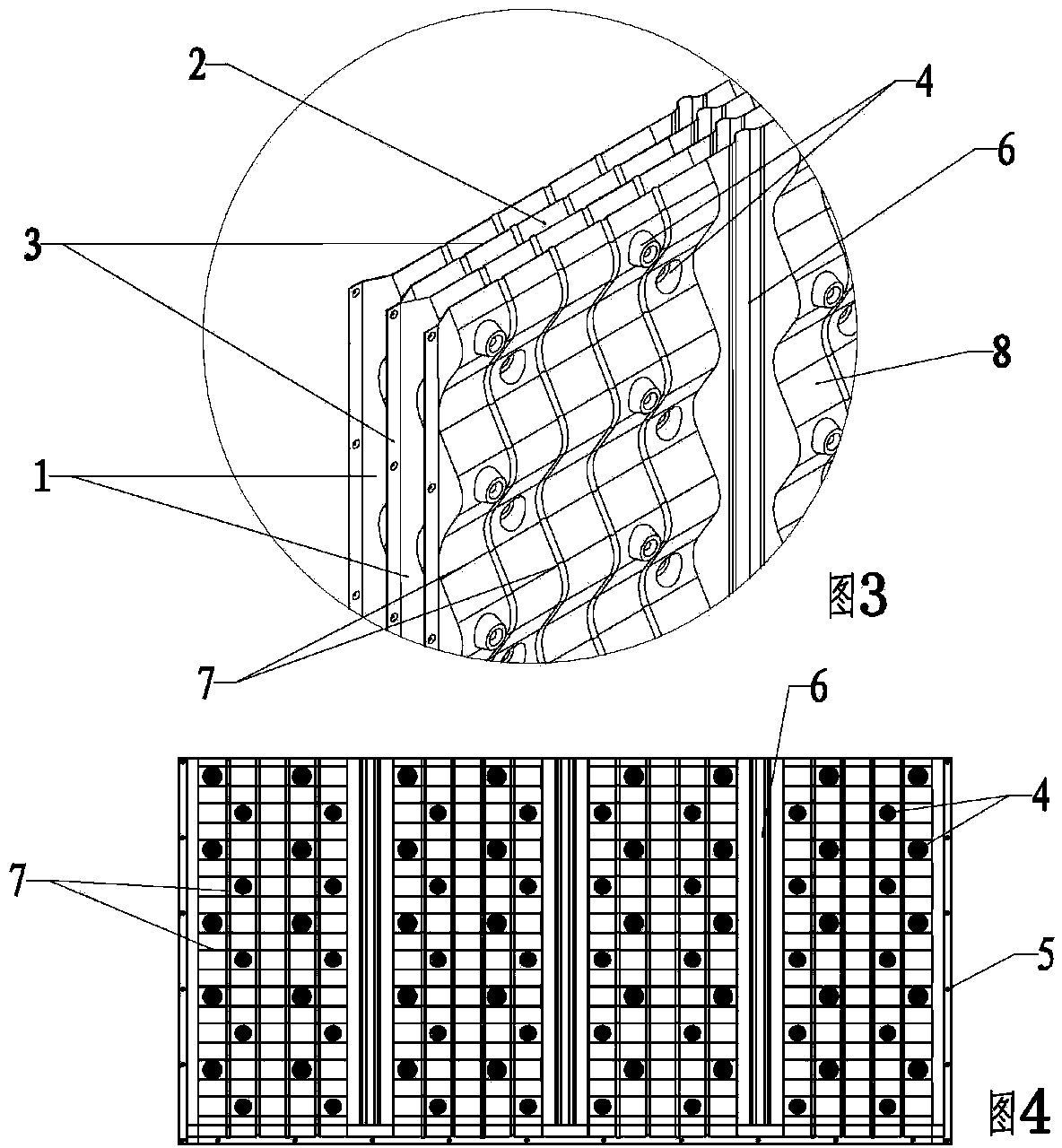

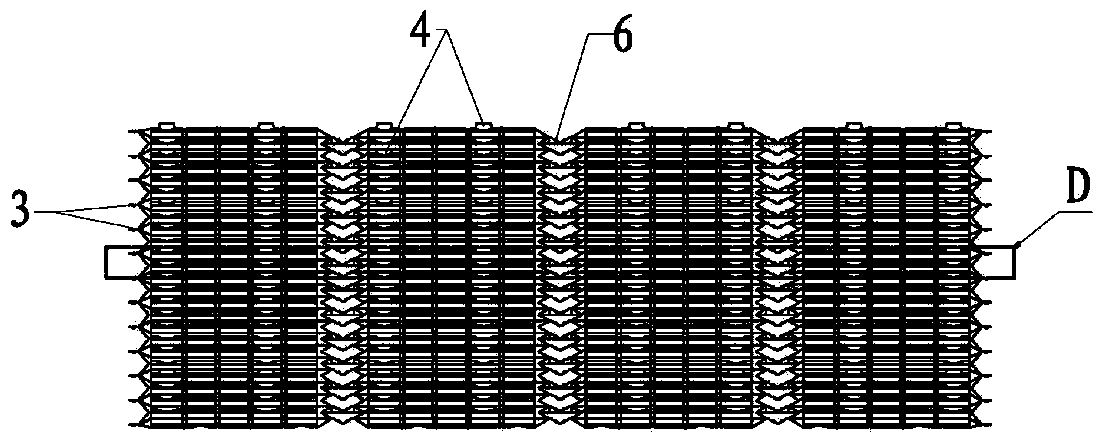

[0022] Such as Figure 1-6 In the shown embodiment, the main body of the air cooler of the present invention is a dual-channel air cooler main body composed of 24 open-type circulating water-gas-liquid orthogonal wave-shaped diaphragms 8 arranged and connected to each other. The side with different isolation and fluid flow directions is the water channel 2, and the other side is the air channel 1. Several pieces of open-type circulating water, gas-liquid orthogonal wave-shaped membrane plates 8 installed in the main body 8 of the air cooler are connected between the air channel 1 and the air channel 1. The windward side of the water channel 2 and the water-facing film panel are formed with a closed edge 3 that completely isolates the air channel 1 and the water channel 2 .

[0023] See attached Figure 1-3 In an embodiment, the open-type circulating water-gas-liquid orthogonal wavy membrane plate 9 is connected with several connection limit fulcrums 4 and connection positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com