Non-contact high-precision calibration method of robot base coordinate system and its application

A technology of base coordinate system and calibration method, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of cumbersome operation, time-consuming, uncontrollable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

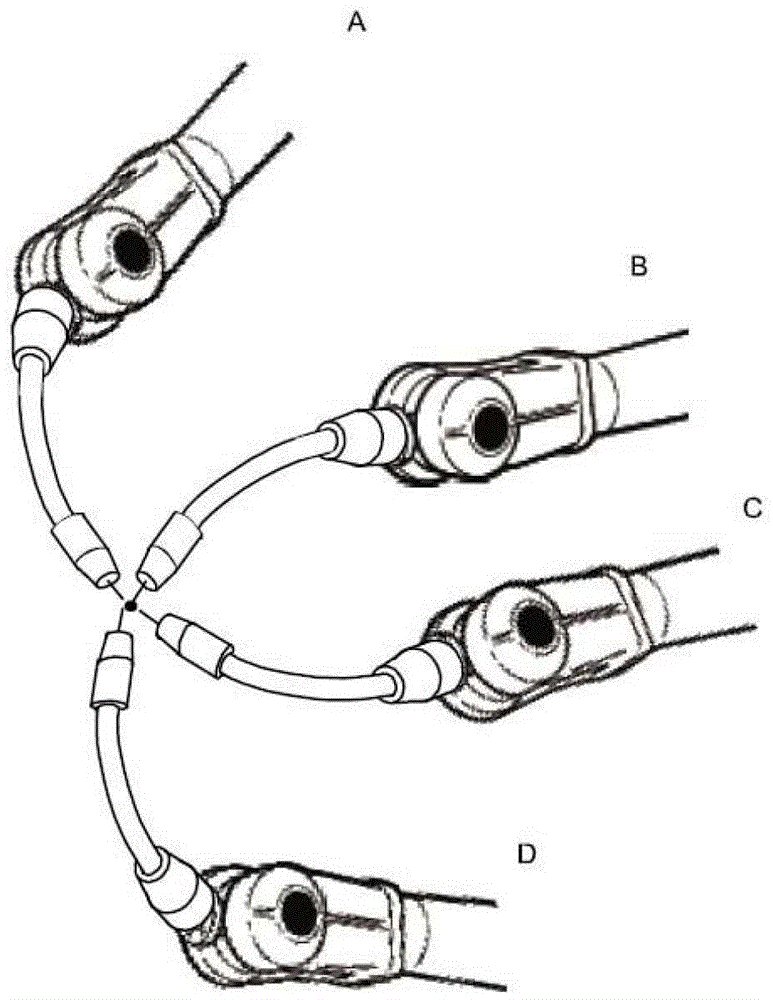

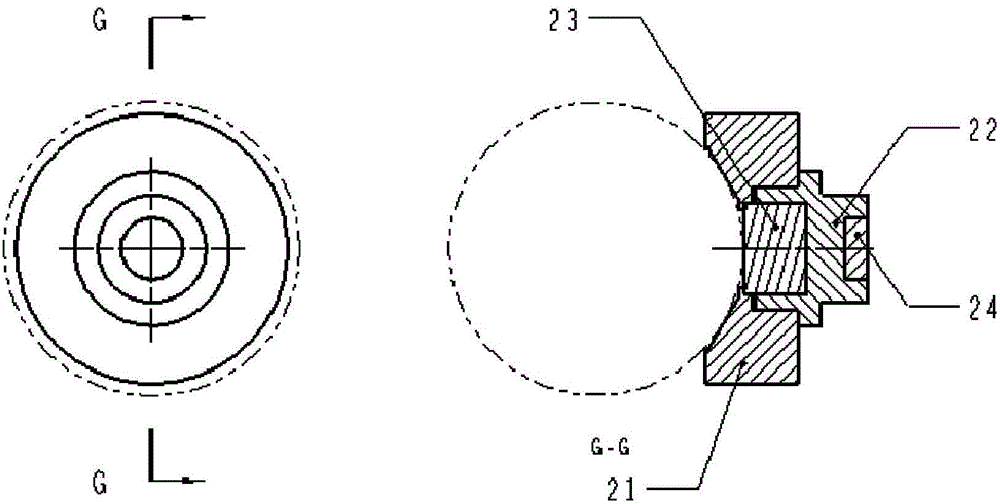

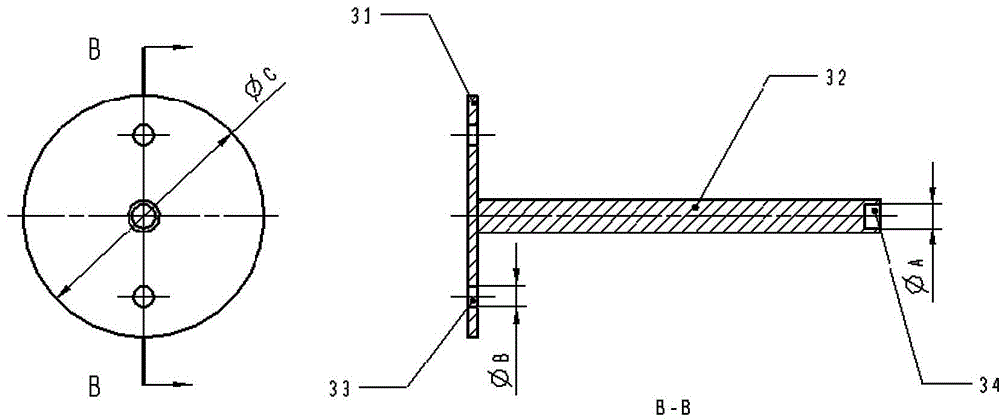

[0149] The non-contact high-precision calibration method of the robot base coordinate system of the present invention adopts the calibration finger tooling installed with the measuring ball, and the calibration finger tooling includes a space point positioning device, a robot flange extension rod, and a circular fitting sleeve; Refers to the installation of the tooling on the robot flange or tool body; the center of the measuring ball (that is, the center point of the measuring ball as the calibration point) is measured by the laser measuring instrument; the laser measuring instrument has a coordinate system of the laser measuring instrument, and the laser measuring instrument The measured data is processed through the algorithm of coordinate transformation, and the relationship between the coordinate system of the laser measuring instrument and the base coordinate system of the robot is established, so as to perform non-contact high-precision calibration of the base coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com