Non-contact high-precision calibration method and application of single robot workpiece coordinate system

A calibration method and non-contact technology, applied in instruments, optical devices, measuring devices, etc., can solve the problems of cumbersome operation, time-consuming, uncontrollable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0449] Example: complex robotic system process and method for recovery relocation.

[0450] system introduction:

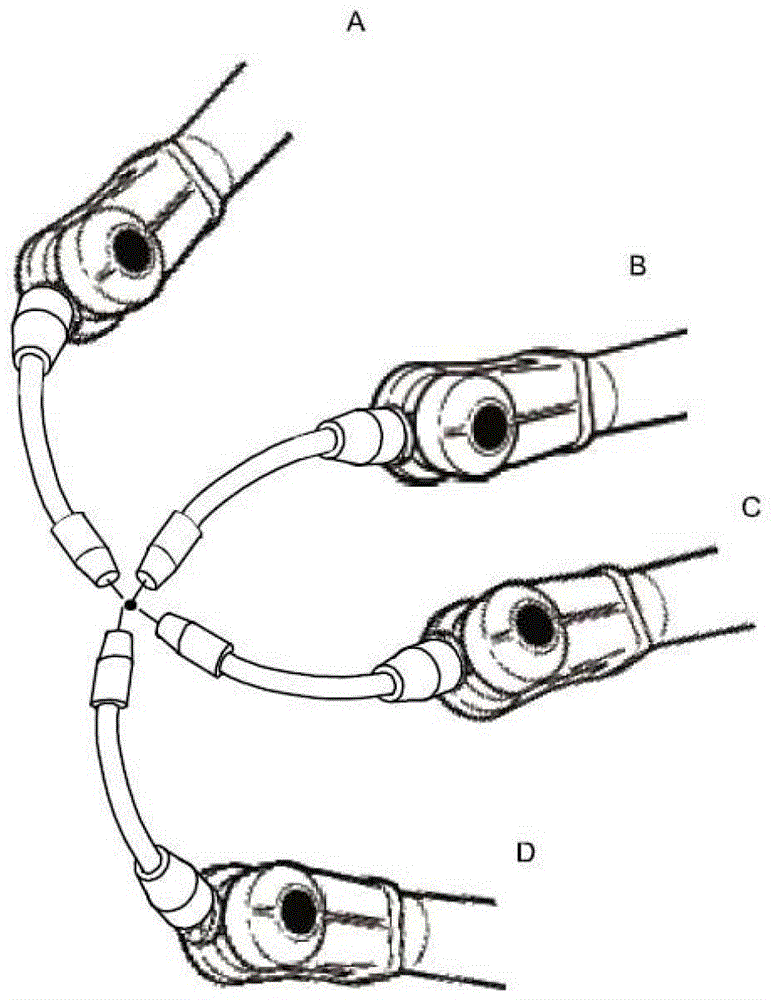

[0451] Such as Figure 8 As shown, the system has 4 robots: R1, R2, R3, R4. R1 has a cooperative relationship with R2 and R3. R4 has a cooperative relationship with R2, and has no cooperative relationship with R3, and R4 operates on the workpiece coordinate system on R3. R1 corresponds to the workpiece coordinate system R w1 , R2 corresponds to the workpiece coordinate system R w1 , R w2 , R3, R4 have no corresponding workpiece coordinate system.

[0452] The system consists of the following elements: e 1 = rob 1 , e 2 = rob 2 , e 3 = rob 3 , e 4 = rob 4 , e 5 = wobj 1 (R w1 for rob 1 ), e 6 = wobj 2 (R w1 for rob 2 ), e 7 = wobj 3 (R w2 for rob 2 ), e 8 = wobj 4 (wobj 4 ∈ rob 3 for rob 4 ), and e before relocation 1 = rob 1 , e 2 = rob 2 , e 3 = rob 3 , e 4 = rob 4 None of the base markings have been modified, so rob 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com