Noise test system and method

A technology for testing systems and noise, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of human ear interference, excessive interference noise, and difficulty in ensuring the consistency of finished air conditioners, and achieve the goal of ensuring consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

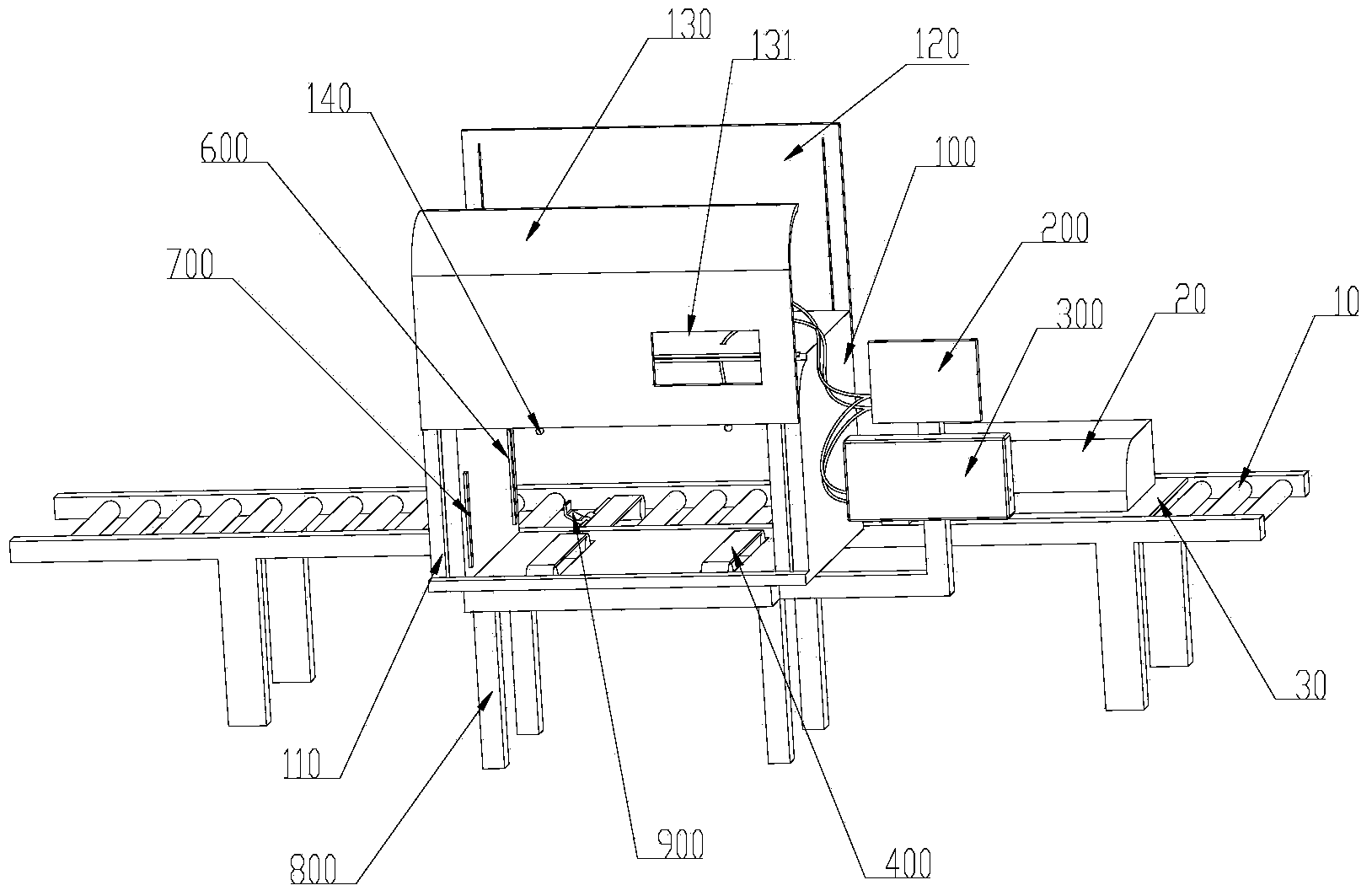

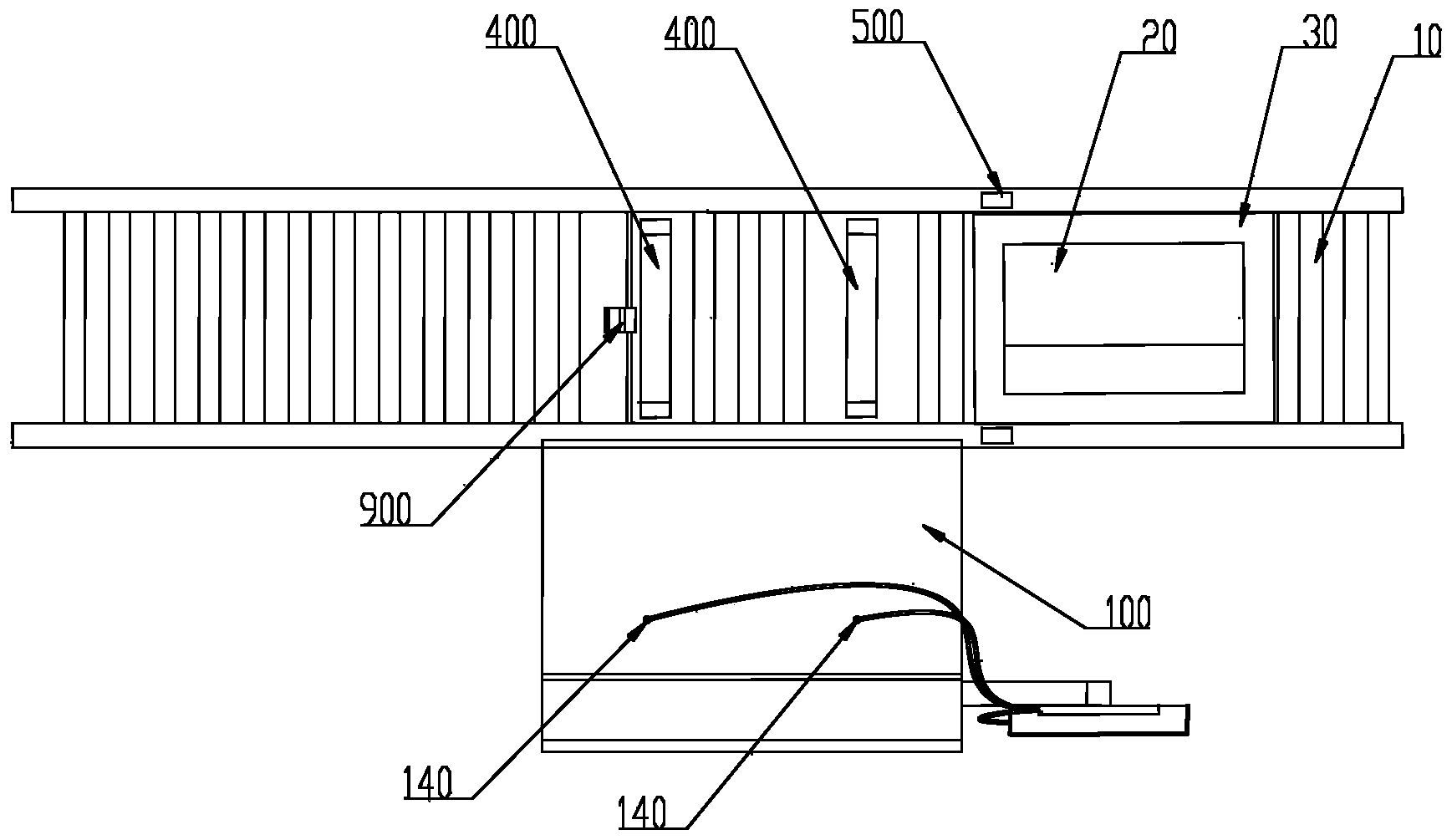

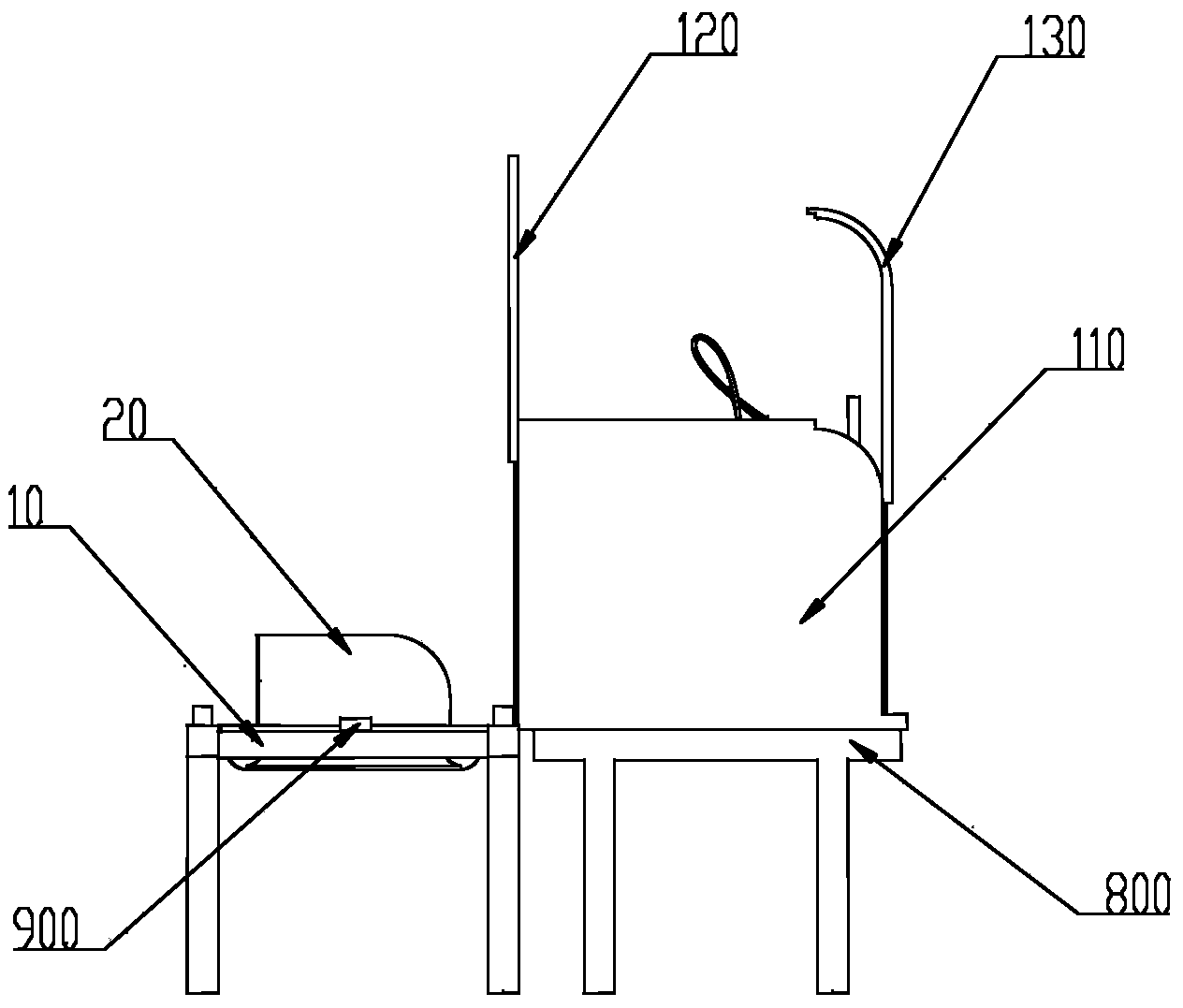

[0042] see Figure 1 to Figure 9 , an embodiment of the noise testing system provided by the present invention includes a silent box 100, a digital display 200 and a power amplifier 300, wherein the silent box 100 is arranged on one side of the production line 10 in parallel, and it can be connected with the production line by screws, bolts, etc. Pipeline 10 is fixed. Specifically, the mute box 100 includes a box body 110 , an entrance and exit door 120 and an observation door 130 . Both the access door 120 and the observation door 130 are electronically controlled doors, which are respectively slidably connected with the box body 110 under the drive of the cylinder, can slide up and down along the box body, and have tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com