Large Aperture Off-Axis Optical System and Passive Athermalization Method

An optical system and large-aperture technology, applied in optics, optical components, installation, etc., can solve the problems of increasing system volume, weight, and cost, and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

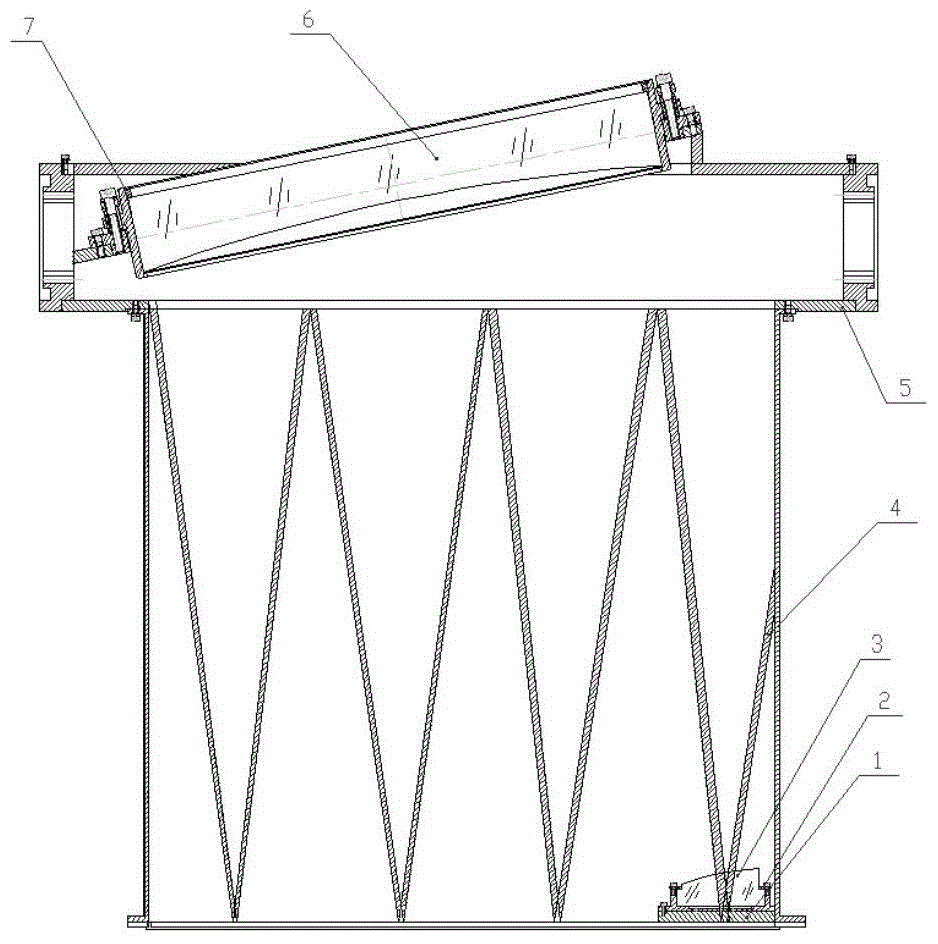

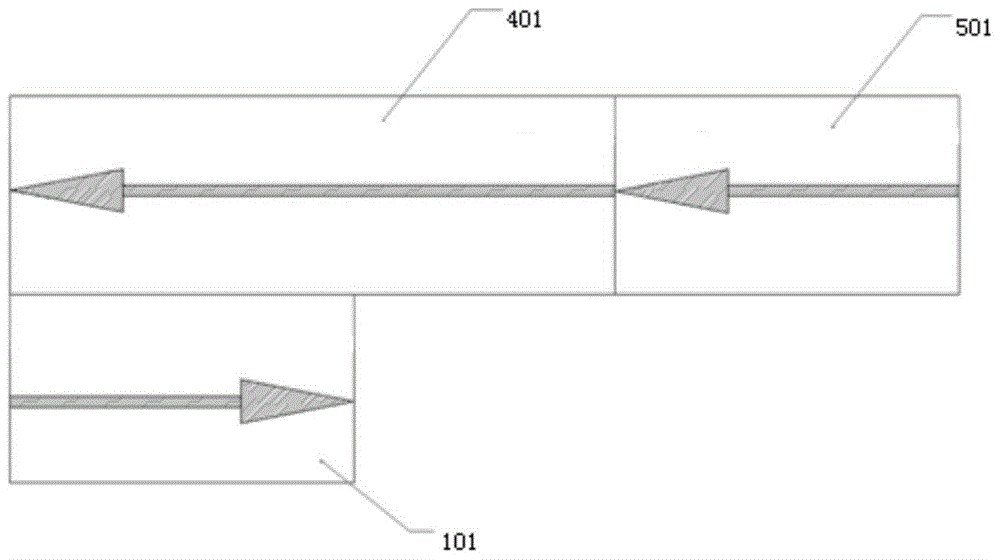

[0029] Embodiment 1: as figure 1 As shown, a large-aperture off-axis optical system includes: a displacement compensation mechanism 1, a secondary mirror chamber 2 with a parabolic secondary mirror 3 installed, a connecting frame 4, a primary mirror frame 5, and a primary mirror with an ellipsoidal primary mirror 6 installed Mirror chamber 7; the bottom of the displacement compensation mechanism 1 and the secondary mirror chamber 2 (the direction is the same as that shown in the accompanying drawing, the upper part of the secondary mirror chamber 2 is equipped with a secondary mirror 3, and the bottom of the secondary mirror chamber 2 faces away from the secondary mirror The upper part of chamber 2) is fixedly connected, the primary mirror frame 5 is fixedly connected with the primary mirror chamber 7, and the primary mirror frame 5 and the secondary mirror chamber 2 are connected by the connecting frame 4; the parabolic secondary mirror 3 and the ellipsoidal primary mirror 6 a...

example

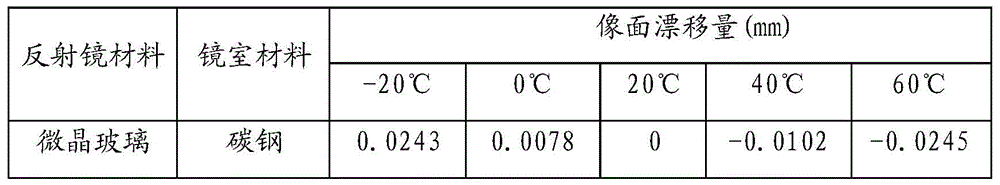

[0045] Table 2

[0046]

[0047] The data in Table 2 is calculated based on the above interval compensation formula. The displacement compensation mechanism 1 prepared by using a 64mm aluminum block can fully compensate the system interval caused by temperature. It effectively guarantees that the image quality of the system does not change with temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com