Preparation process of ashitaba fermented tea

A production process and technology for fermenting tea, applied in the field of beverages, can solve the problems of incompletely exerted nutritional and health care functions, difficult leaching of macromolecular nutrients, lack of fragrance of ordinary tea leaves, etc. thick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

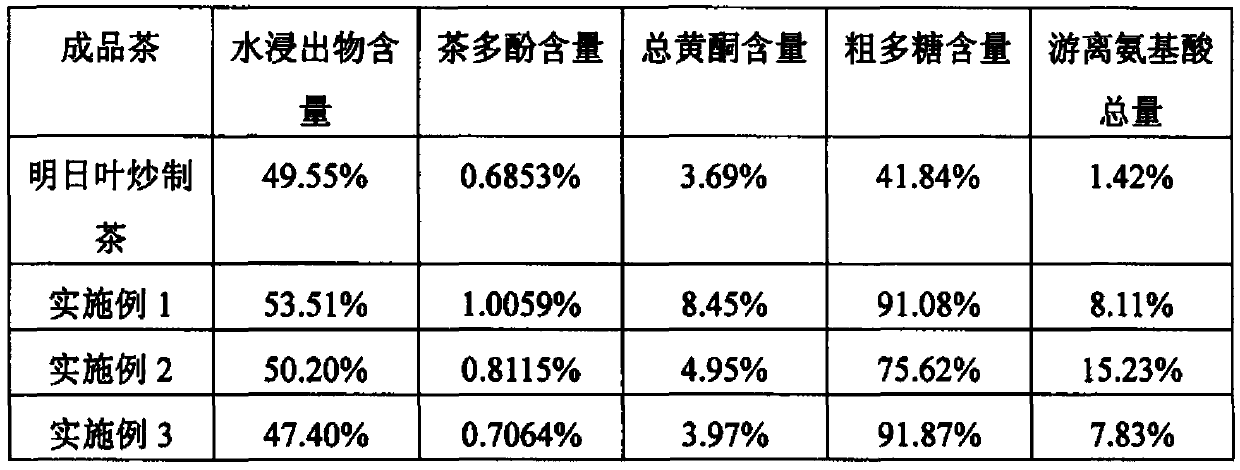

Examples

Embodiment 1

[0031] Cleaning: pick the fresh leaves of Ashitaba after 30 days of growth, remove the stalks, wash with water and remove the water;

[0032] Spreading and withering: spread the washed and dehydrated Ashitaba for 8 hours, turn the pile 4 times, and turn the pile once every 2 hours;

[0033] Temperature drift: water temperature 60 ℃, time 30 seconds;

[0034] Water shake: time 3 minutes;

[0035] Cutting: Cut Ashitaba into small pieces of about 8cm×4cm;

[0036] Baking (withering in hot air): drying with hot air at low temperature, the temperature at the air outlet is 60°C, the time is 15 minutes, and the pile is turned 8 times during the baking;

[0037] Kneading: Spray cellulase with an enzyme activity of 190 units during the rolling process, and the amount of cellulase added is 0.15g / 100g fresh leaves;

[0038] Fermentation: Put the kneaded ashitaba into the fermentation room for fermentation. The fermentation temperature is 37° C., the relative humidity is 97%, and the ...

Embodiment 2

[0044] Cleaning: pick the fresh leaves of Ashitaba after 30 days of growth, remove the stalks, wash with water and remove the water;

[0045] Spreading and withering: spread the washed and dehydrated Ashitaba for 8 hours, turn the pile 4 times, and turn the pile once every 2 hours;

[0046] Temperature drift: water temperature 60 ℃, time 30 seconds;

[0047] Water shake: time 3 minutes;

[0048] Cutting: Cut Ashitaba into small pieces of about 8cm×4cm;

[0049] Baking (withering in hot air): drying with hot air at low temperature, the temperature at the air outlet is 60°C, the time is 15 minutes, and the pile is turned 8 times during the baking;

[0050] Kneading: Spray a medium-temperature amylase with an enzyme activity of 9816 units during the rolling process, and the amount of the medium-temperature amylase added is 0.015g / 100g of fresh leaves;

[0051] Fermentation: Put the kneaded ashitaba fermented tea into the fermentation room for fermentation. The fermentation te...

Embodiment 3

[0057] Cleaning: pick the fresh leaves of Ashitaba after 30 days of growth, remove the stalks, wash with water and remove the water;

[0058] Spreading and withering: spread the washed and dehydrated Ashitaba for 8 hours, turn the pile 4 times, and turn the pile once every 2 hours;

[0059] Temperature drift: water temperature 60 ℃, time 30 seconds;

[0060] Water shake: time 3 minutes;

[0061] Cutting: Cut Ashitaba into small pieces of about 8cm×4cm;

[0062] Baking (withering in hot air): drying with hot air at low temperature, the temperature at the air outlet is 60°C, the time is 15 minutes, and the pile is turned 8 times during the baking;

[0063] Kneading: Spray pectinase with an enzyme activity of 5718 units during the rolling process, and the amount of pectinase added is 0.015g / 100g fresh leaves;

[0064] Fermentation: Put the kneaded ashitaba fermented tea into the fermentation room for fermentation. The fermentation temperature is 37° C., the relative humidity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com