Gas-liquid mixing cyclone

A gas-liquid mixing and cyclone technology, which is used in cyclone devices, mixing methods, chemical instruments and methods, etc., can solve problems such as low separation efficiency, and achieve the effect of improving separation efficiency and increasing specific gravity difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

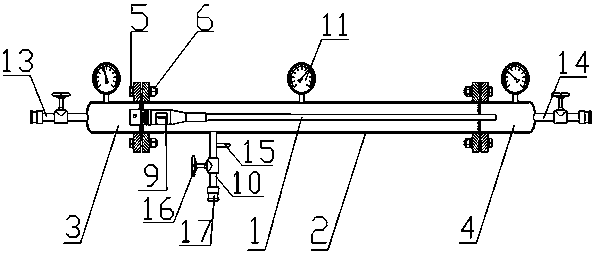

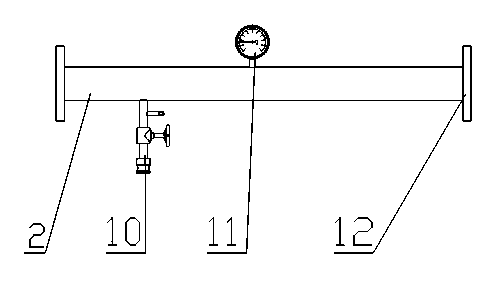

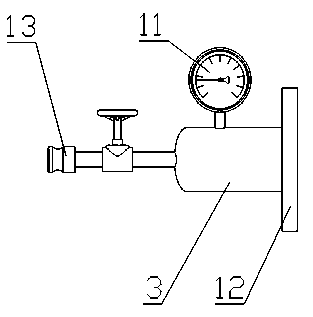

[0017] figure 1 Among them, the present invention includes a cylinder body 2, a left head 3 and a right head 4 installed at both ends of the cylinder body 2, and the inner cavity of the cylinder body 2 is equipped with a swirl pipe 1 for separating oil and sewage. One end of the cylinder 2 is provided with a large end hole for installing the large end of the swirl tube 1 , and the other end of the cylinder 2 is provided with a small end hole for installing the small end of the swirl tube 1 . The large end of the swirl tube 1 extends into the inner cavity of the left head 3, the small end of the swirl tube 1 extends into the inner cavity of the right head 4, and the middle part of the swirl tube 1 is placed in the inner cavity of the cylinder body 2; the middle part of the swirl tube 1 is close to The big end is provided with a tangential inlet 9. The swirl tube 1 communicates with the inner cavity of the cylinder body 2 through the tangential inlet 9 . The inner cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com