Equipment and method for removing and recovering sludge at the bottom of a crude oil storage tank

A technology for crude oil storage tanks and recovery equipment, which is applied in the field of cleaning and recovery of sludge at the bottom of crude oil storage tanks. It can solve the problems of inability to use the main cleaning cycle system in series, high operating costs, and poor economy, and achieves reductions in cleaning treatment costs and equipment. The effect of low investment and improved operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

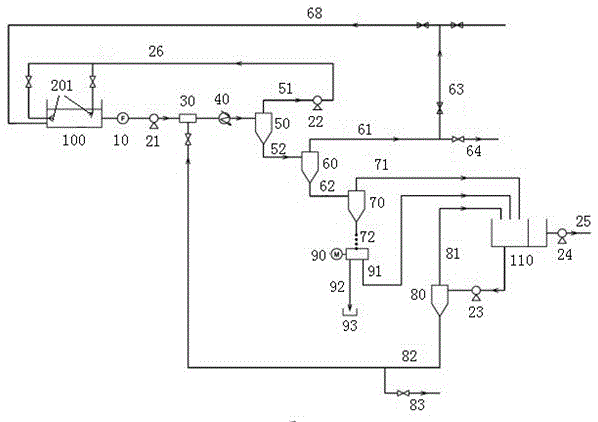

[0053] Such as figure 1 As shown, the suction pump 21 extracts the "oil-water-sand" mixture from the cleaned crude oil storage tank 100, and the "oil-water-sand" passes through the filter 10 before the pump and flows into the mixer 30; The water storage side in the type oil-water separator 110 is drawn out, and through the deoiling hydrocyclone 80, the deoiling hydrocyclone 80 further separates the water containing a small amount of oil from the gravity type oil-water separator 110, and the rich The oily water flows back to the oil-water separator 110 from the overflow port, and the oil-poor water flows out from the bottom flow port, and is input into the mixer 30 through the pipeline 82, and the used mixer is a static mixer. Here, water is thoroughly mixed with the "oil-water-sand" mixture from the crude oil storage tank 100, and the amount of water added should be sufficient to make the volume content of water in the material in the mixer 30 greater than 50%, and to ensure t...

Embodiment 2

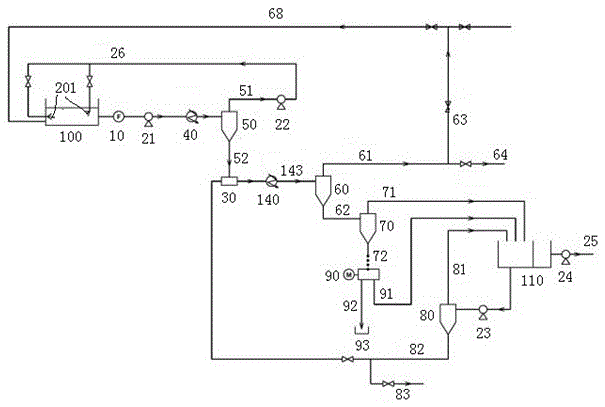

[0060] Such as figure 2 As shown, the suction pump 21 extracts the "oil-water-sand" mixture from the cleaned crude oil storage tank 100, passes through the pre-pump filter 10, flows into the heater 40, and heats up to a suitable temperature for cleaning and hydrocyclone separation.

[0061] The heated material enters the screening hydrocyclone 50, where the "oil-water-sand" mixture is initially separated into two parts with a smaller specific gravity and a larger specific gravity. The split ratio of the screening hydrocyclone 50 is controlled so that the overflow The flow rate out of the outlet matches the flow rate of the cleaning pump 22, and the lighter material with more oil and less water and sand flowing out from the overflow port passes through the first pipeline 51, the cleaning cleaning pump 22, and then is sprayed at high pressure by the cleaning nozzle 201 to On the sludge at the bottom of the crude oil storage tank 100, the sludge is cut, stirred, and under the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com