A compound screening machine

A sieving machine and compound technology, which is applied in the direction of sieving, solid separation, and separation of solids from solids with airflow, can solve the problems of continuous gradation of particles, easy accumulation of sieve surface, large mud powder content, etc. Achieve the effect of improving reliability and durability, strong reliability, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

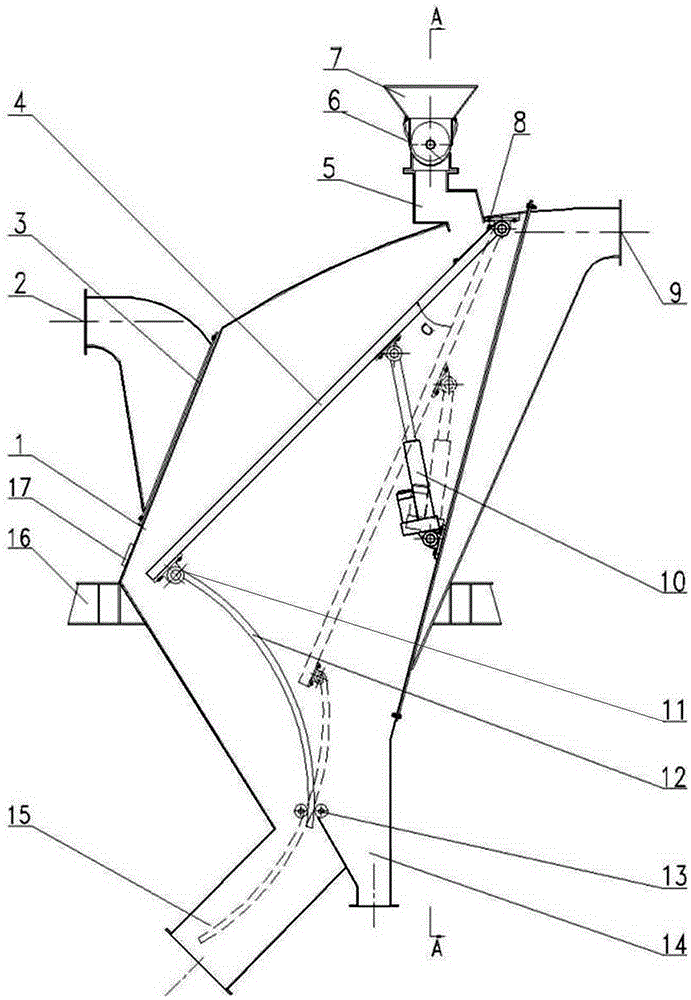

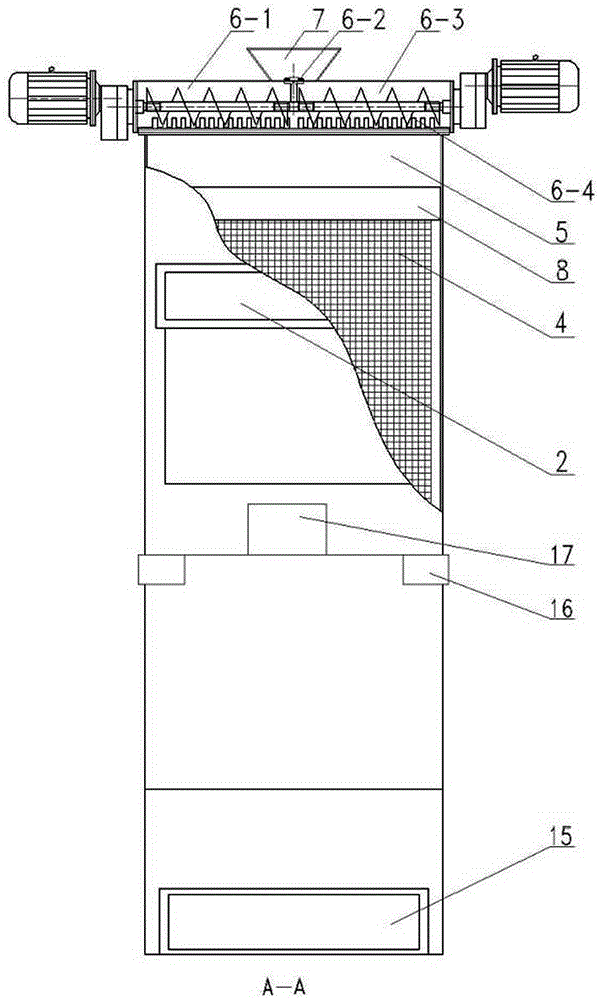

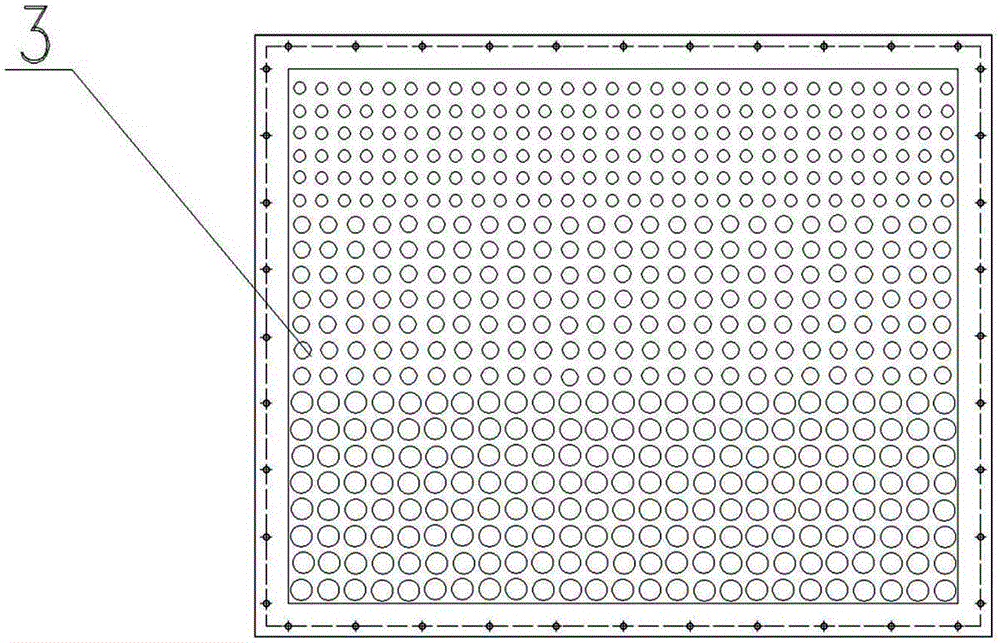

[0026] Such as figure 1 and 2 Shown, a kind of composite screening machine comprises screen box, air inlet, feed hopper, screen cloth, material discharge port; The present invention is characterized in that, air inlet 2 is opened on screen box 1 top, and between air inlet 2 and screen box 1 is provided with air distribution plate 3; feed hopper 7 is set on the top of screen box 1, and below feed hopper 7 is set as feed conduit 5; between feed hopper 7 and feed conduit 5 is provided with spiral cloth machine 6; the upper end of the screen 4 is fixed on the inner wall of the screen box 1 and is hinged to the rear side of the feed conduit 5; the lower end of the screen 4 is hinged to the upper end of an arc-shaped material partition 12; Between the rollers 13 fixed on the inner wall of the screen box 1; an electric push rod 10 is hingedly connected to the back of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com