Outer skin of sport ball and production process thereof

A production process and technology for sports balls, which are applied in the field of sports ball skins and their production processes, can solve the problems of insufficient three-dimensionality, poor touch feeling, and poor anti-slip effect, and achieve the effects of good anti-slip effect, soft touch and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The sports ball skin in this embodiment is made by the following process:

[0025] Make the main body of the skin; this step adopts the process of the prior art, and will not be repeated here;

[0026] Steps for forming non-slip bumps on skin body:

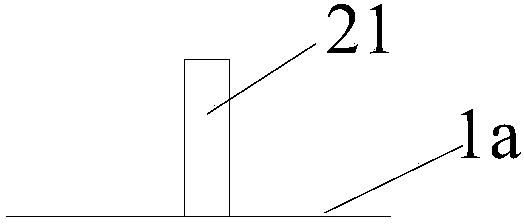

[0027] The silicone material for printing is repeatedly overprinted 10 times on the surface of the outer skin body by printing process at room temperature to form cylindrical needle-shaped protrusions. The diameter of the cylindrical needle-shaped protrusions is 1mm and the height is 5mm. The interval is 2 to 3 minutes. Between two adjacent printings, the main body of the skin is baked in an oven at a temperature of 90°C.

[0028] During baking, the oven moves over the body of the skin.

[0029] During the baking process, the moving speed of the oven during baking is 8 m / min.

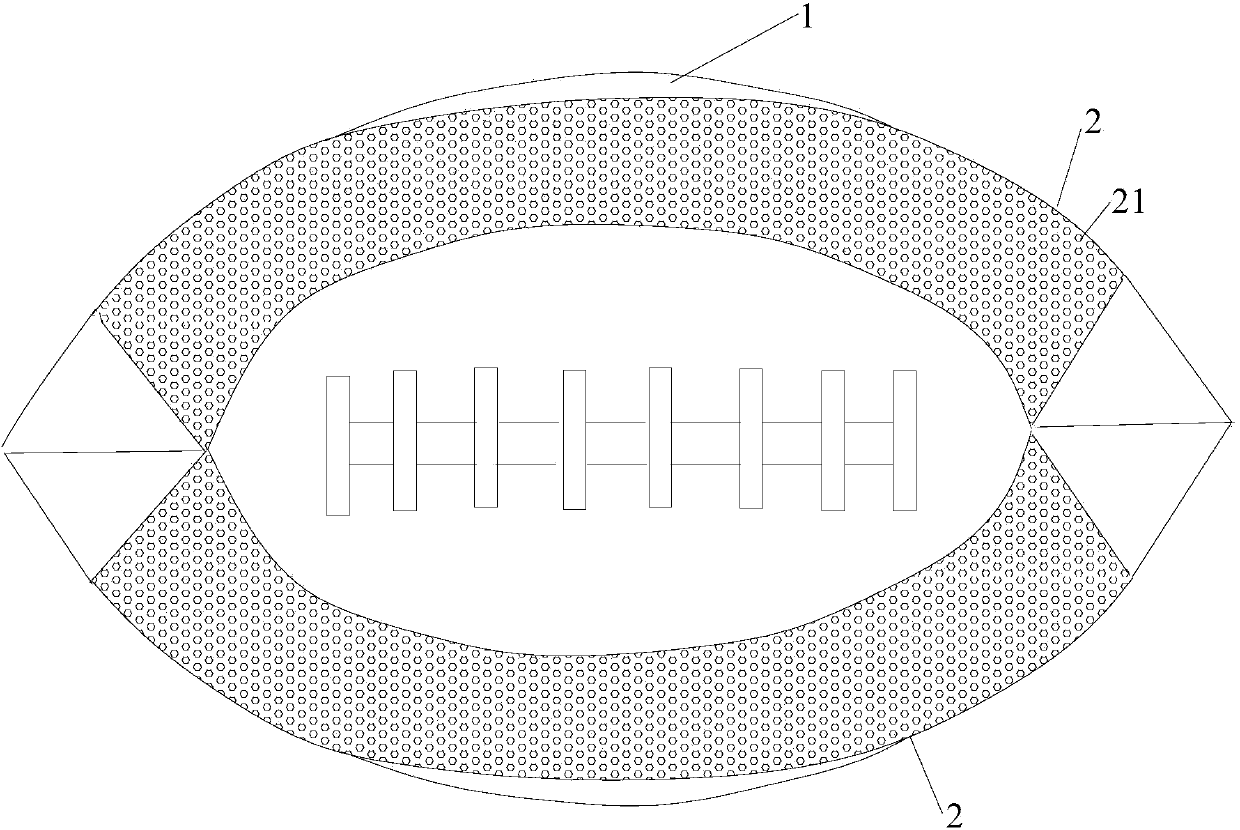

[0030] The sports ball skin that present embodiment forms is rugby skin, see figure 1 , figure 2 , the sports ball skin includes a skin main ...

Embodiment 2

[0032] The sports ball skin in this embodiment is made by the following process:

[0033] Make the main body of the skin; this step adopts the process of the prior art, and will not be repeated here;

[0034] Steps for forming non-slip bumps on skin body:

[0035] The rubber material for printing is repeatedly overprinted 8 times on the surface of the main body of the skin through the printing process to form cylindrical needle-shaped protrusions. The diameter of the cylindrical needle-shaped protrusions is 1.5 mm and the height is 4 mm. The interval between two adjacent printings should be 2 ~3 minutes. Between two adjacent printings, an oven with a temperature of 100° C. is used to bake the main body of the skin.

[0036] During baking, the oven moves over the body of the skin.

[0037] During the baking process, the moving speed of the oven during baking is 9 m / min.

Embodiment 3

[0039] The sports ball skin in this embodiment is made by the following process:

[0040] Make the main body of the skin; this step adopts the process of the prior art, and will not be repeated here;

[0041] Steps for forming non-slip bumps on skin body:

[0042] The TPR material for printing is repeatedly overprinted 10 times on the surface of the main body of the skin by printing technology to form cylindrical needle-shaped protrusions. The diameter of the cylindrical needle-shaped protrusions is 2 mm and the height is 5 mm. The interval between two adjacent printings should be 2~ 3 minutes. Between two adjacent printings, an oven with a temperature of 110° C. is used to bake the main body of the skin.

[0043] During baking, the oven moves over the body of the skin.

[0044] During the baking process, the moving speed of the oven during baking is 10 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com