Automatic cleaning structure and method for heater wire of bag making machine

An automatic cleaning, electromechanical technology, applied in container manufacturing machinery, paper/cardboard containers, containers, etc., can solve problems such as odor generation, affecting heat conduction of heating wires, and reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

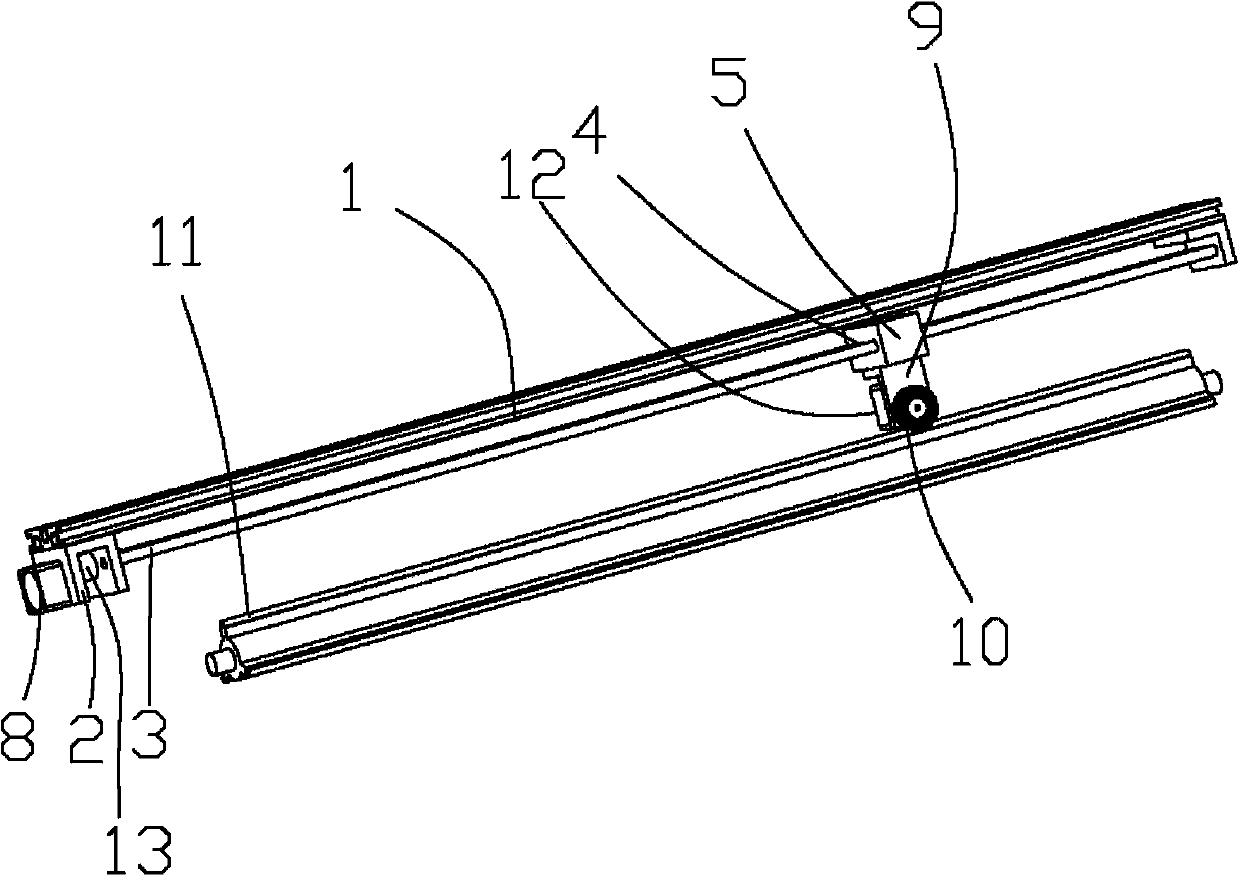

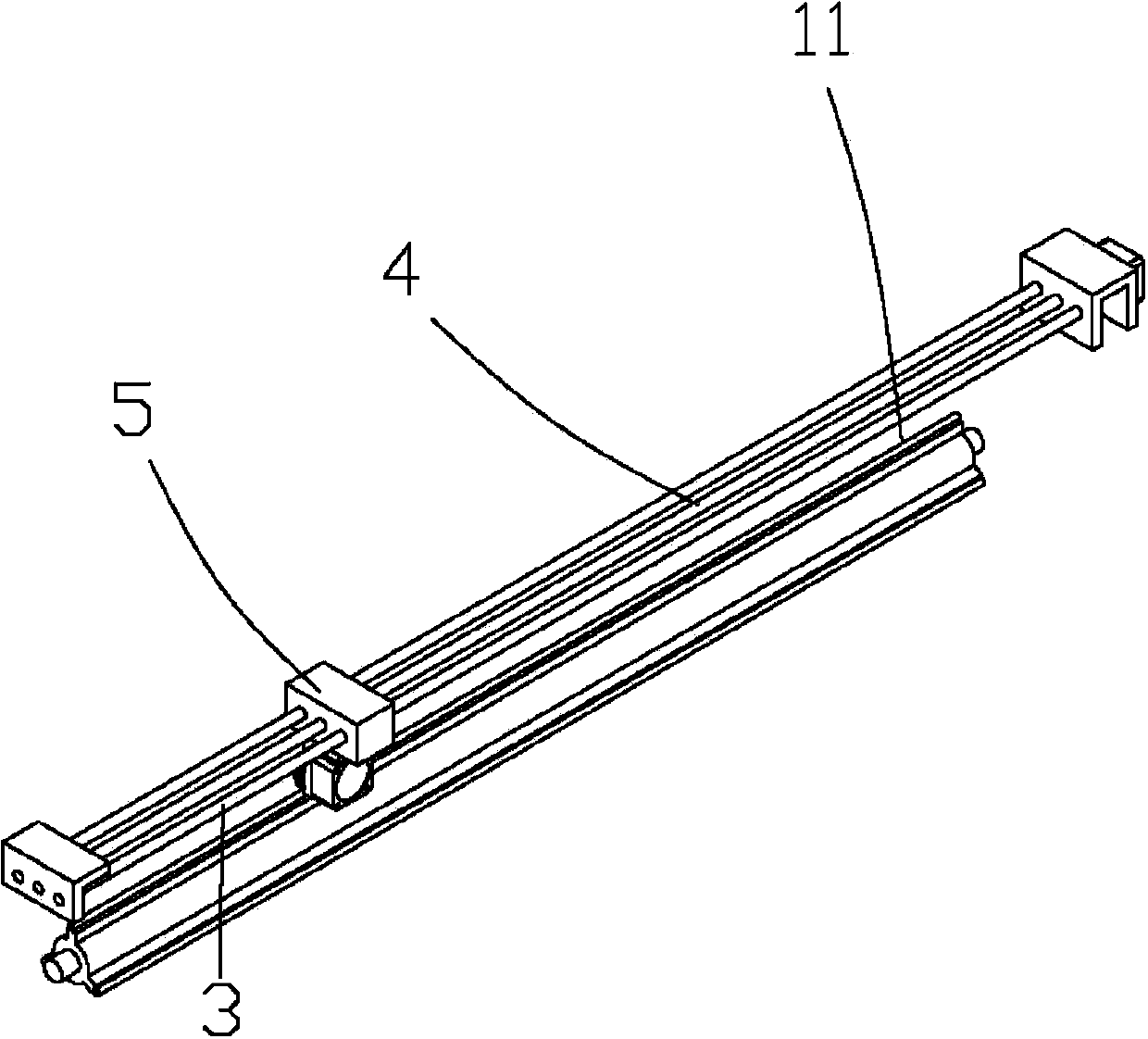

[0013] refer to figure 1 , figure 2 , the present invention discloses a structure and method for quickly cleaning plastic residues on the surface of a heating wire without stopping the machine.

[0014] Power mechanism is made up of cylindrical guide rail 3, leading screw 4, leading screw nut 5, leading screw driving motor 8 and shaft coupling 13; Fixed wire brush driving motor 12 on the motor support 9, and the shaft end of wire brush driving motor 12 is fixed with Steel wire brush 10, motor support 9 are fixed on the leading screw nut 5, do linear motion with leading screw nut 5.

[0015] When the heating wire 11 is in a static state, the screw drive motor 8 drives the screw 4 to rotate through the coupling 13 so that the wire brush drive motor 12 fixed with the screw nut 5 moves linearly along the two cylindrical guide rails 3 At the same time, the wire brush 10 is driven by the wire brush drive motor 12 to rotate at a high speed to clean the heating wire 11 quickly.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com