Automobile fender with double-layer fabrics and preparation process of automobile fender

A technology of double-layer fabrics and fenders, applied in the direction of lamination, layered products, lamination devices, etc., can solve the problems of high noise, heavy weight, easy to break fenders, etc., and achieve good sound absorption effect and light weight. , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment one: The low-melting-point fiber adopts the low-melting-point fiber of modified PET, and the melting point is 110~120°C.

[0021] The hollow fibers are hollow PET fibers. Fender fabric skin density is 100g / m 2 , fender mixed fiber felt density is 950g / m 2 .

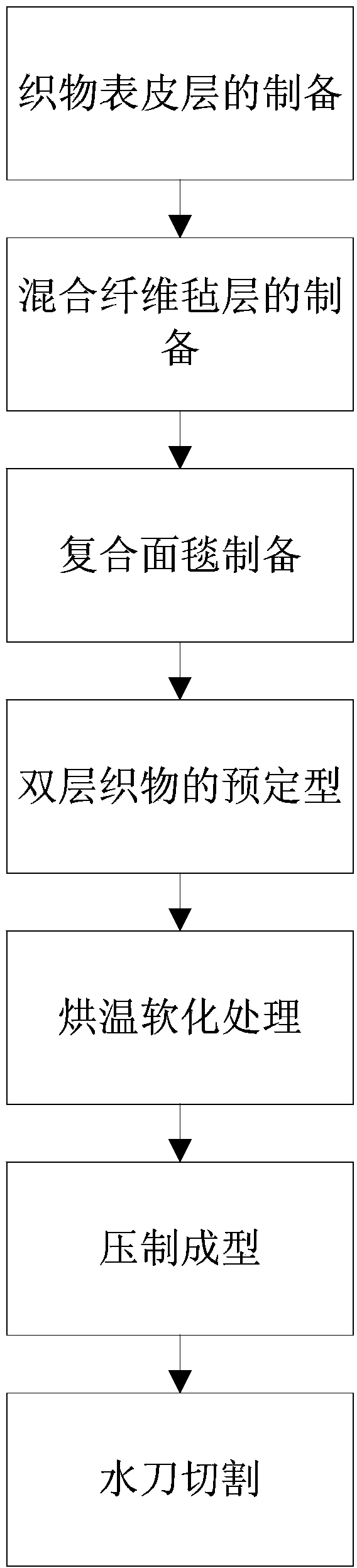

[0022] A kind of automobile double-layer fabric fender preparation process, comprises the steps:

[0023] (1) Preparation of the fabric skin layer: 75 parts by weight of polyester fiber and 25 parts by weight of polypropylene fiber are mixed, carded, laid and needled to make the skin layer of the fabric. The frequency of pre-needling is 490HZ, and the frequency of down-needling is 32HZ , the upper acupuncture frequency is 30HZ;

[0024] (2) Preparation of mixed fiber mat layer: 40 parts by weight of low melting point fiber, 10 parts by weight of hollow fiber, and 50 parts by weight of polyester fiber were mixed, carded, laid and needled to prepare a mixed fiber felt layer, and the pre-needling freq...

Embodiment 2

[0030] Embodiment two : The low-melting-point fiber adopts low-melting-point fiber of modified PET, and the melting point is 110~120°C. The hollow fibers are hollow PET fibers. The density of the fender fabric skin layer is 125g / m 2 , the density of the fender mixed fiber felt layer is 1025g / m 2 .

[0031] A kind of automobile double-layer fabric fender preparation process, comprises the steps:

[0032] (1) Preparation of the fabric skin layer: 77.5 parts by weight of polyester fiber and 22.5 parts by weight of polypropylene fiber were mixed, carded, laid and needled to make the fabric skin. The upper acupuncture frequency is 32HZ;

[0033] (2) Preparation of mixed fiber felt layer: 45 parts by weight of low-melting fiber, 12.5 parts by weight of hollow fiber, and 42.5 parts by weight of polyester fiber were mixed, carded, laid and needled to prepare a mixed fiber felt, and the frequency of pre-needling was 490HZ, the lower acupuncture frequency is 33HZ, and the upper a...

Embodiment 3

[0040] Embodiment three: The low-melting-point fiber adopts the low-melting-point fiber of modified PET, and the melting point is 110~120°C. The hollow fibers are hollow PET fibers. The density of the fender fabric skin layer is 150g / m 2 , the density of the fender mixed fiber felt layer is 1100g / m 2 .

[0041] A kind of automobile double-layer fabric fender preparation process, comprises the steps:

[0042] (1) Preparation of fabric skin layer: 75 parts by weight of polyester fiber and 25 parts by weight of polypropylene fiber are mixed, carded, laid and needled to make a fabric skin. The frequency of pre-needling is 510HZ, and the frequency of lower needling is 35HZ. The upper acupuncture frequency is 35HZ;

[0043] (2) Preparation of mixed fiber felt layer: 50 parts by weight of low-melting fiber, 15 parts by weight of hollow fiber, and 45 parts by weight of polyester fiber were mixed, carded, laid and needled to prepare a mixed fiber felt. The pre-needling frequency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap