Compound support leg disk mounting device for engineering vehicle

A technology for engineering vehicles and installation devices, applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve problems affecting vehicle transfer and off-road driving performance, affecting vehicle driving stability, and vehicle gap failure. Improve site adaptability and off-road driving performance, save labor time and work intensity, and increase the effect of minimum ground clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

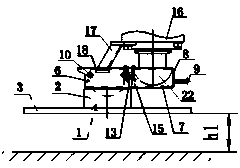

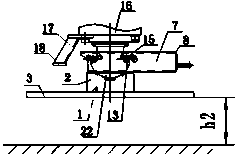

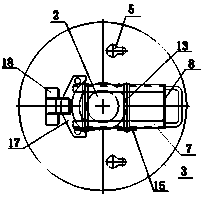

[0026] The present invention will be further described in detail below in conjunction with the drawings.

[0027] Such as Figure 1 to Figure 12 As shown, the composite foot plate installation device of the engineering vehicle includes a leg cylinder 16 and a foot plate 1. The foot plate 1 includes a welded and fixed bottom plate 3 and a ball socket 2. The top of the ball socket 2 is provided with a spherical shape In the groove, the bottom plate 3 is provided with two special-shaped pin holes 5, each of the special-shaped pin holes 5 includes two connected circular holes of different diameters; on the top of the ball socket 2 is fixedly connected a carriage 6, the carriage 6 includes two parallel and spaced apart The channel steel 7, the connecting plate 8 connecting the front end of the two channel steel 7, the handle 9 fixedly connected to the connecting plate 8, the notches of the two channel steel 7 are arranged oppositely, and the rear end of the lower leg plate of the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com