Drive axle shaft tube assembly for electric estate car

A station wagon and tube assembly technology, applied to axles, wheels, vehicle parts, etc., can solve the problems of difficult to ensure passenger-carrying operation of electric vehicles, troublesome disassembly and assembly, adjustment of the main reducer, poor shock and noise reduction, and poor braking effect and other issues, to achieve the effect of safe and stable passenger-carrying operation, material saving, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

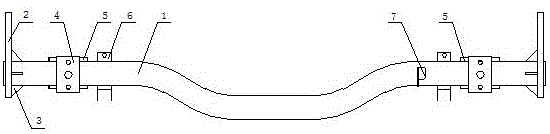

[0018] Below in conjunction with accompanying drawing, the embodiment of this electric station wagon drive axle shaft tube assembly is described in further detail:

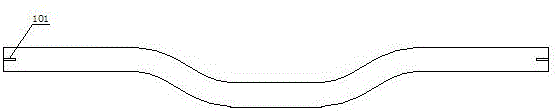

[0019] The axle tube assembly of the drive axle of the electric station wagon is composed of an elbow 1, a bottom plate 2, a reinforcing rib 3, a leaf spring seat 4, a reinforcing ring 5, a shock absorber bracket 6, and a line pipe bracket 7, and both ends of the elbow 1 are welded symmetrically. The bottom plate 2 is installed, and the reinforcement rib 3 is welded on the bottom plate 2, and the reinforcement rib 3 is welded and fixed with the elbow 1; Reinforcing ring 5 is welded at the rear; shock absorber bracket 6 is welded symmetrically on the side close to leaf spring seat 4 on elbow 1; wire pipe bracket 7 is welded on the right side of elbow 1 near shock absorber bracket 6 .

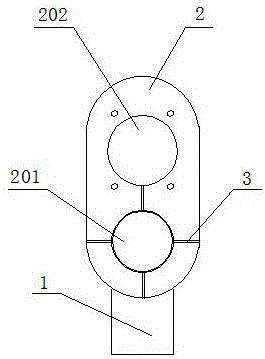

[0020] The bottom plate 2 is formed with a small mounting hole 201 and a large mounting hole 202, the bottom plate 2 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com