High-ground-clearance full-time four-wheel-drive rice transplanter

A high ground clearance, rice transplanter technology, applied in the direction of transplanting machinery, mechanical equipment, planting methods, etc., can solve the problems that affect the normal transplanting and growth of rice, the difficulty of ordinary rice transplanter operation, the increase of the depth of mud feet in paddy fields, etc., and achieve the passing performance Good, strong driving force, the effect of enhancing driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

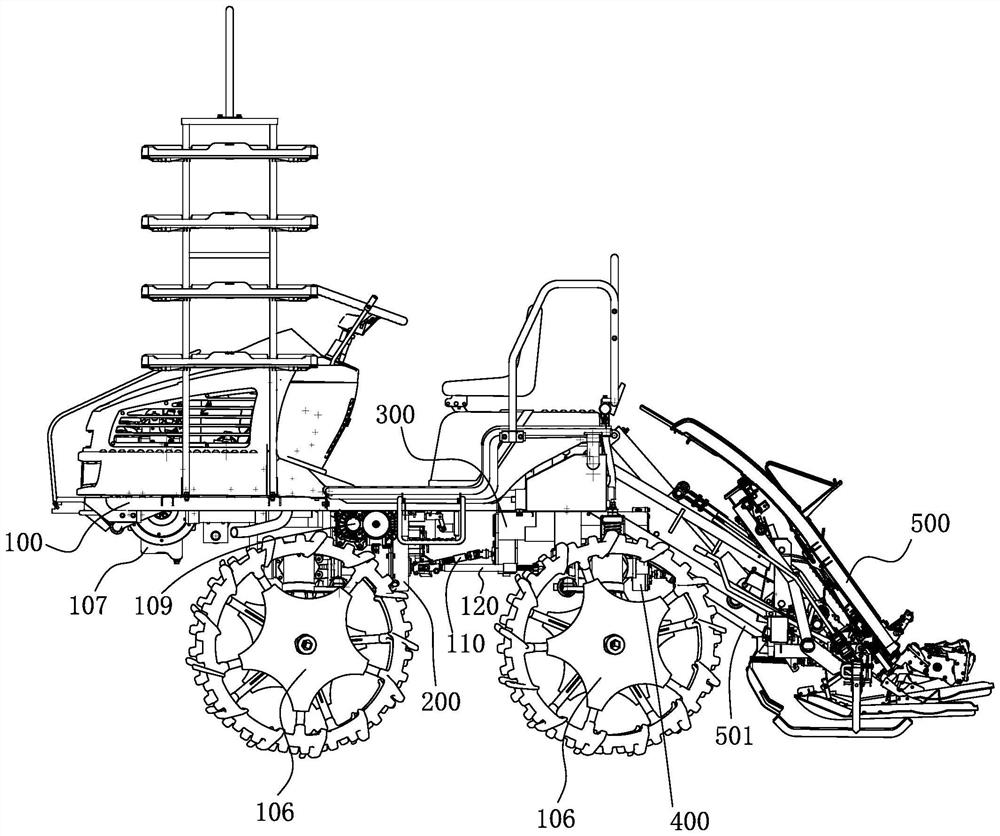

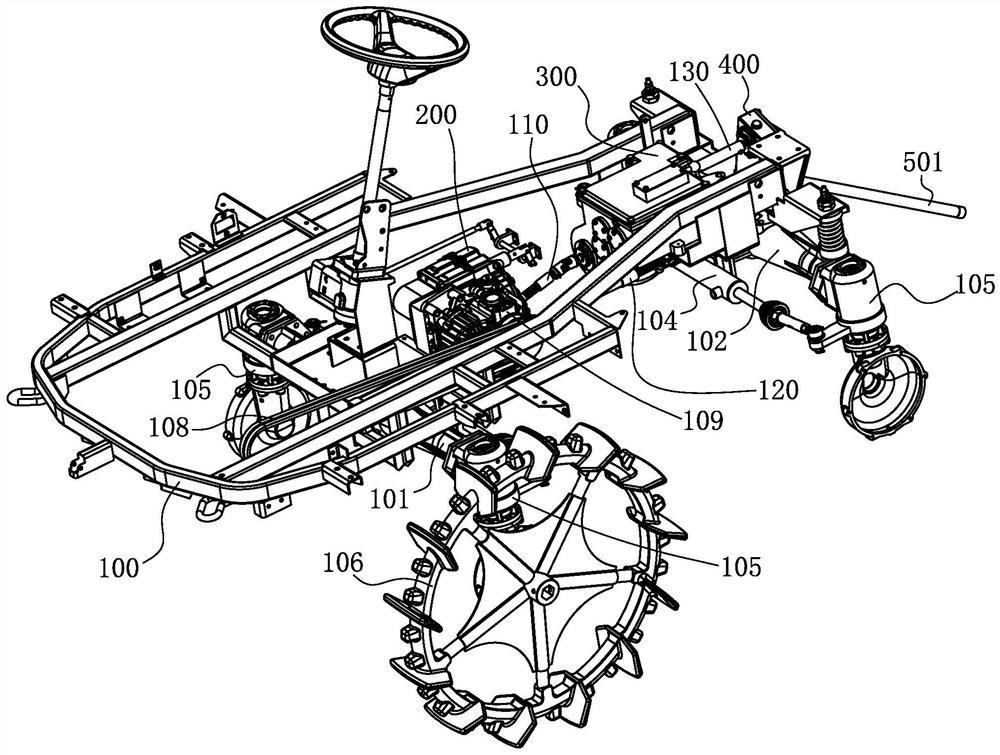

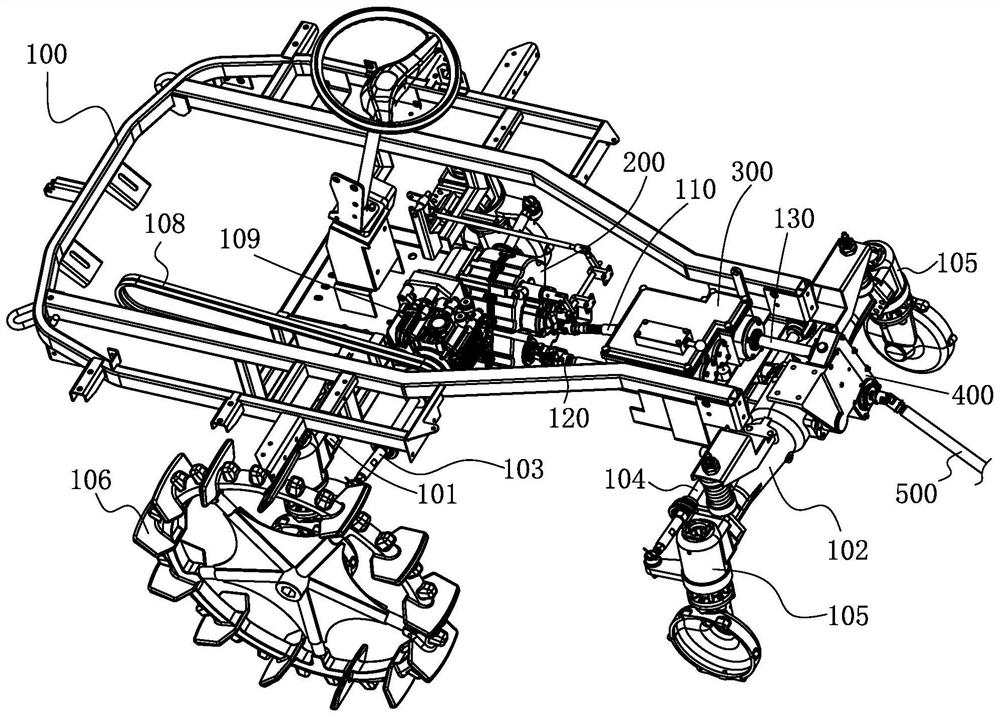

[0039] Such as Figure 1 ~ Figure 3 As shown, a full-time four-wheel drive rice transplanter with high ground clearance, front drive axle 101, rear drive axle 102 and transmission system are installed on the frame 100. Fixedly connected with the frame 100, the rear drive axle 102 is hinged with the frame 100, the front drive axle 101 is provided with a front steering oil cylinder 103, the rear drive axle 102 is provided with a rear steering oil cylinder 104, the two ends of the front drive axle 101 and the rear drive axle The two ends of 102 are respectively provided with a final drive device 105, and the final drive device 105 includes a steering knuckle housing 105A and an end housing 105B that are rotatably mounted together (see Figure 12 , will be described in detail later), the output shaft of the front drive axle 101 and the output shaft of the rear drive axle 102 are respectively connected with the input shaft of the corresponding final drive 105, and the output shaft ...

Embodiment 2

[0068] The structure of embodiment 2 is basically the same as that of embodiment 1. The difference is that the walking gearbox and the plant-to-plant distance gearbox are integrated into a walking-plant-to-plant-distance integrated gearbox, and the walking-to-plant-distance integrated gearbox is connected to the engine transmission. The plant-to-plant integrated gearbox includes a walking output shaft and a transfer shaft for transplanting rice. One end of the walking output shaft is in transmission connection with the front drive axle, and the other end of the walking output shaft is in transmission connection with the rear drive axle. The transfer shaft is in transmission connection with the transition box. Setting the traveling gearbox and the plant-to-plant-to-plant gearbox as a whole will make the transmission system more compact. As long as the overall size is properly controlled, it will not affect the minimum ground clearance of the rice transplanter increased by raisin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com