Tin core laminated rubber bearing seat for base isolation

A technology of laminated rubber bearing and foundation isolation, which can be used in infrastructure engineering, earthquake prevention, construction, etc., can solve problems such as environmental pollution and human health damage, and achieve increased damping and early stiffness, high bearing capacity, and large damping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

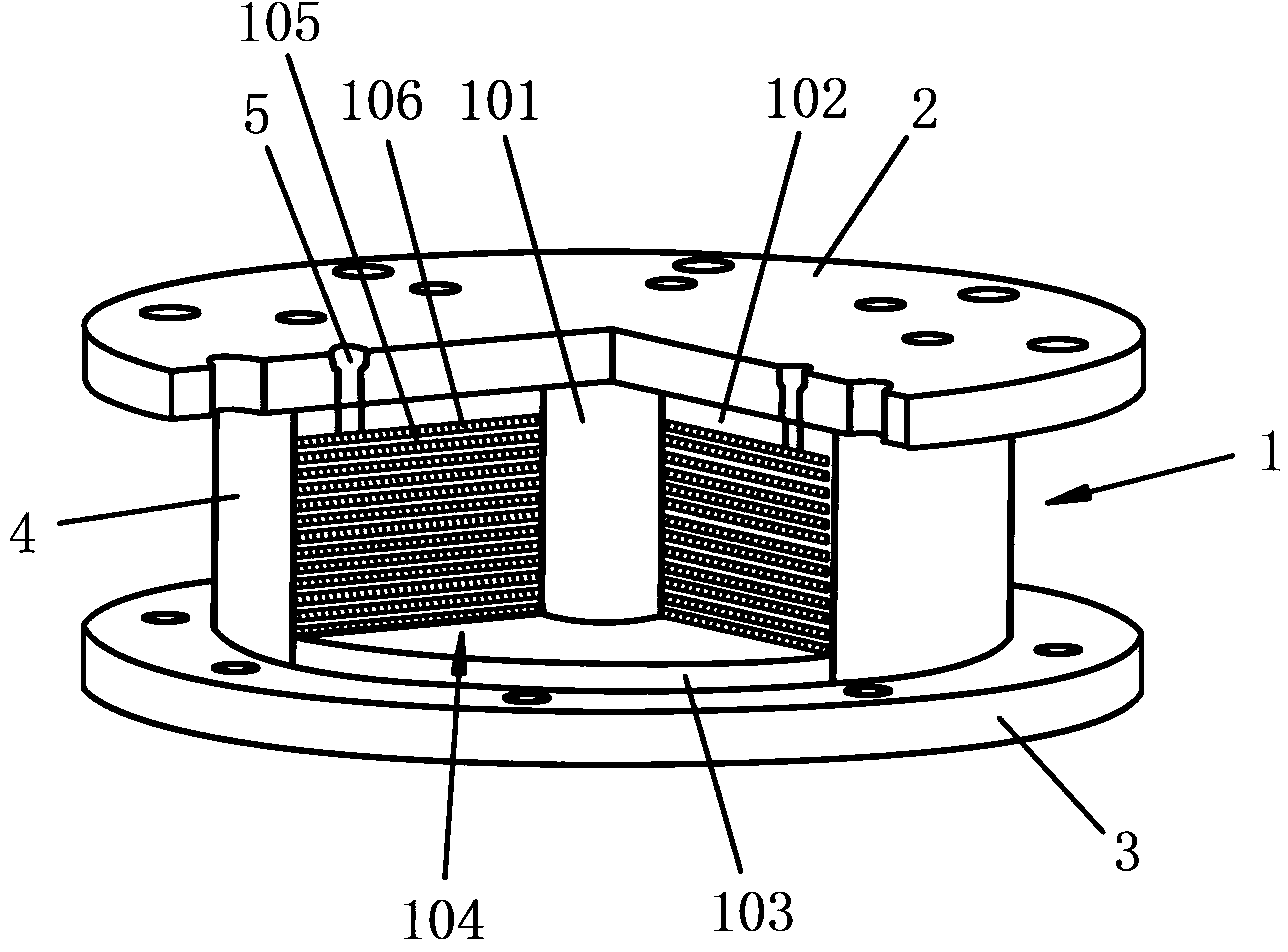

[0015] Such as figure 1 As shown, a tin-core laminated rubber bearing for base shock isolation includes a body 1, an upper connecting steel plate 2 and a lower connecting steel plate 3, a rubber protective layer 4 is pasted on the side of the body 1, and the upper connecting steel plate 2 and the lower connecting plate The steel plate 3 is provided with bolt holes 5, and is fixed on the body 1 by bolts. The body 1 includes a tin mandrel 101, an upper sealing plate 102, a lower sealing plate 103 and a laminated body 104, and the laminated body 104 is located on the upper sealing plate 102 and the lower sealing plate 103, the laminated body 104 is formed by successively stacking stiffened steel plates 105 and rubber plates 106, and the tin mandrel 101 passes through the upper sealing plate 102, the laminated body 104 and the lower sealing plate in sequence 103.

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com