Water diversion and drainage system for mixing frame curtain wall

A drainage system and curtain wall technology, applied in the direction of walls, building components, building insulation materials, etc., can solve the problems of curtain wall water seepage, water seepage, unreliable sealant, etc., and achieve the effect of avoiding water accumulation, wide application, and preventing curtain wall leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

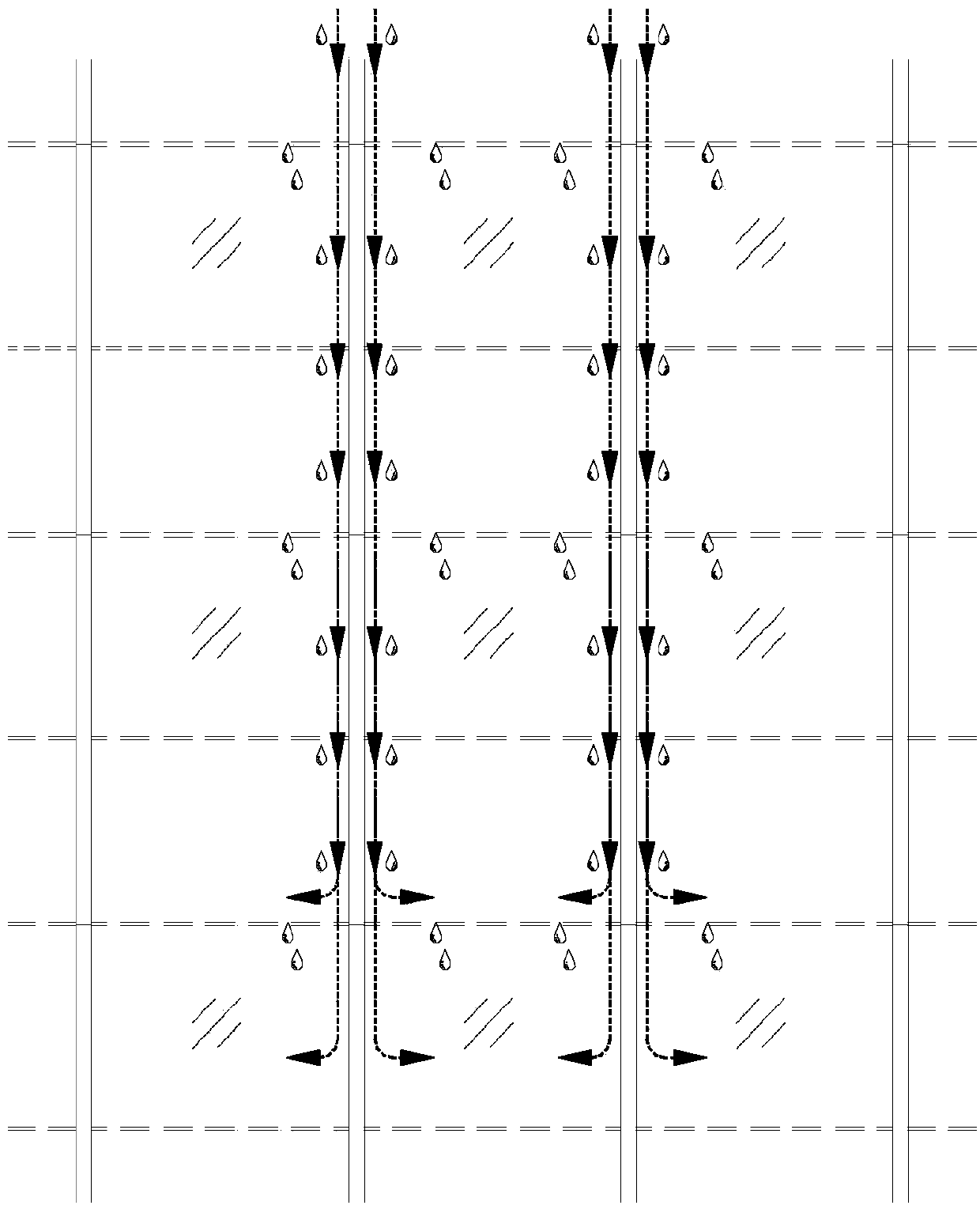

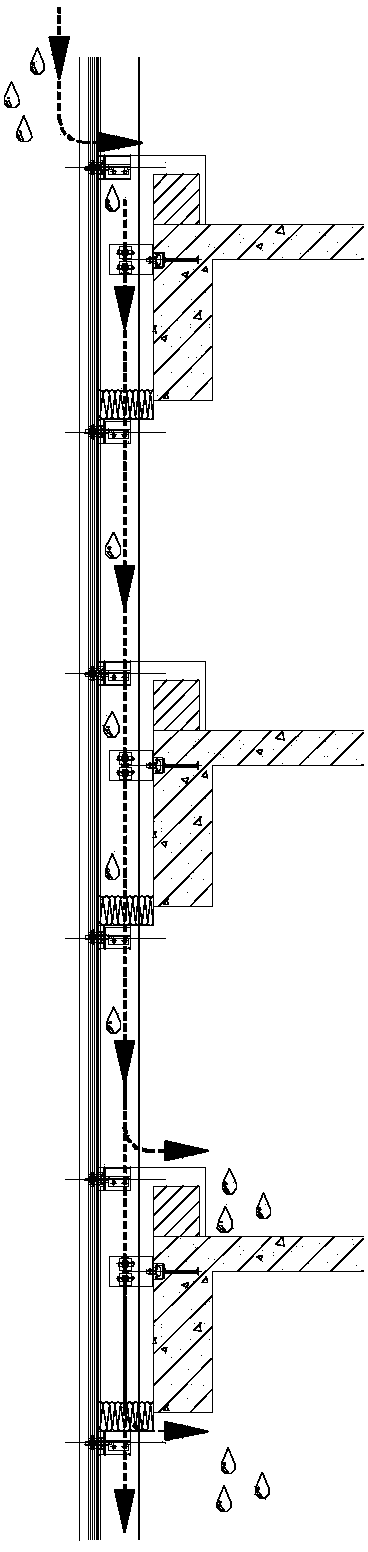

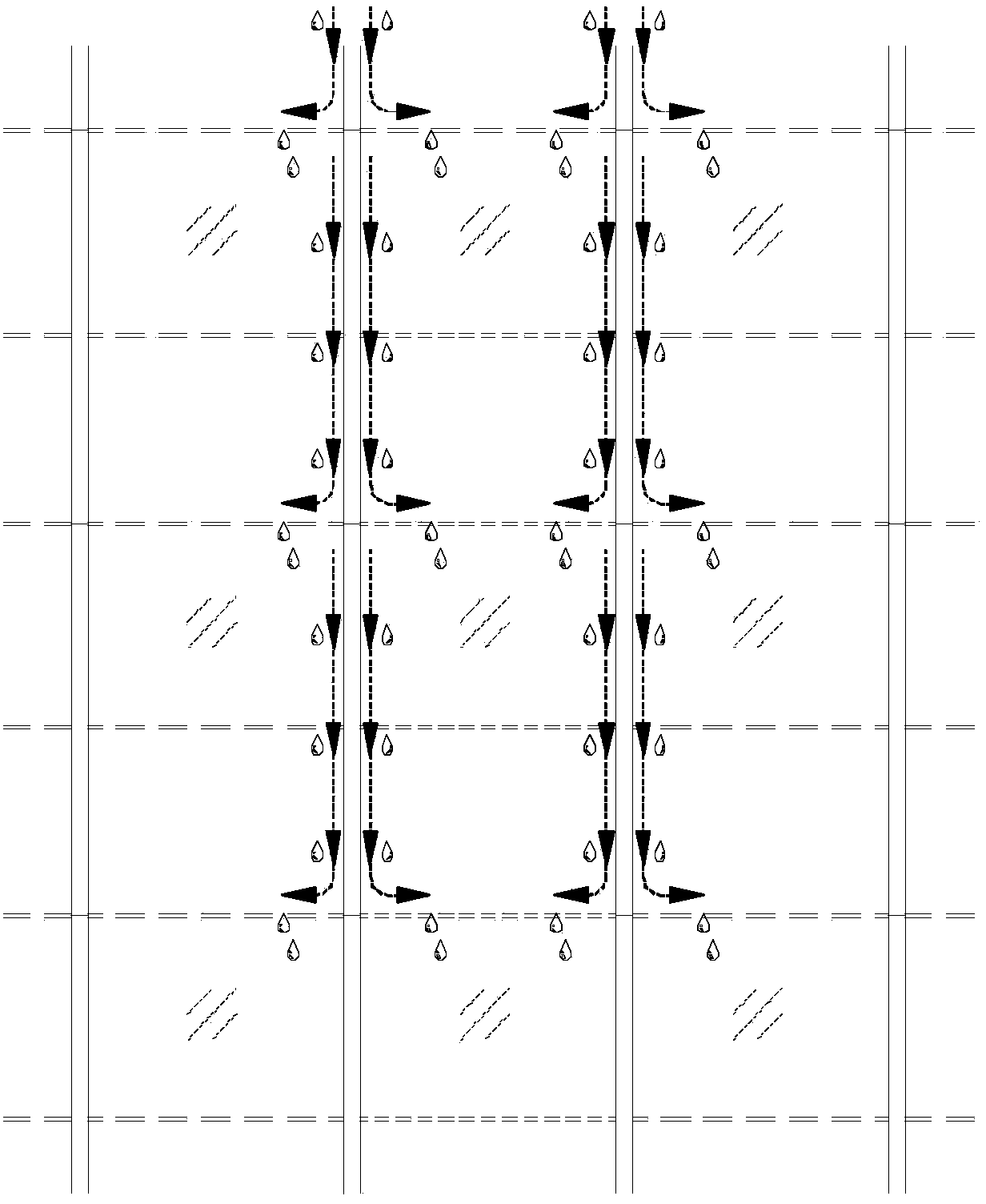

[0021] The water guide and drainage system with high waterproof function described in the present invention includes EPDM water guide tank 1, steel screw 2, plastic buckle cover 3, plastic baffle plate 4, aluminum alloy column 5, hollow glass 6, aluminum alloy pressure plate 7, aluminum alloy Buckle cover 8, sealant 9, aluminum alloy beam 10, EPDM sealant strip 11.

[0022] The EPDM water channel 1 is arranged between the aluminum alloy column 5 and the cavity between the hollow glass 6, and the edge of the EPDM water channel is sealed with a sealant; the EPDM sealing strip 11 is embedded in the aluminum alloy platen 7 with the hole opened, and the aluminum The alloy pressure plate is connected and fixed with the aluminum alloy column 5, the opening position of the aluminum alloy pressure plate is inserted into the drainage ditch of the EPDM water channel 1, the plastic buckle cover 3 is fixed on the opening position of the aluminum alloy pressure plate 7 by the steel screw 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com