Micro thermal power generation device

A power generation device, thermal power technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problems of large vibration, noise, circuit influence, etc., to achieve the effect of high power density, symmetrical structure, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

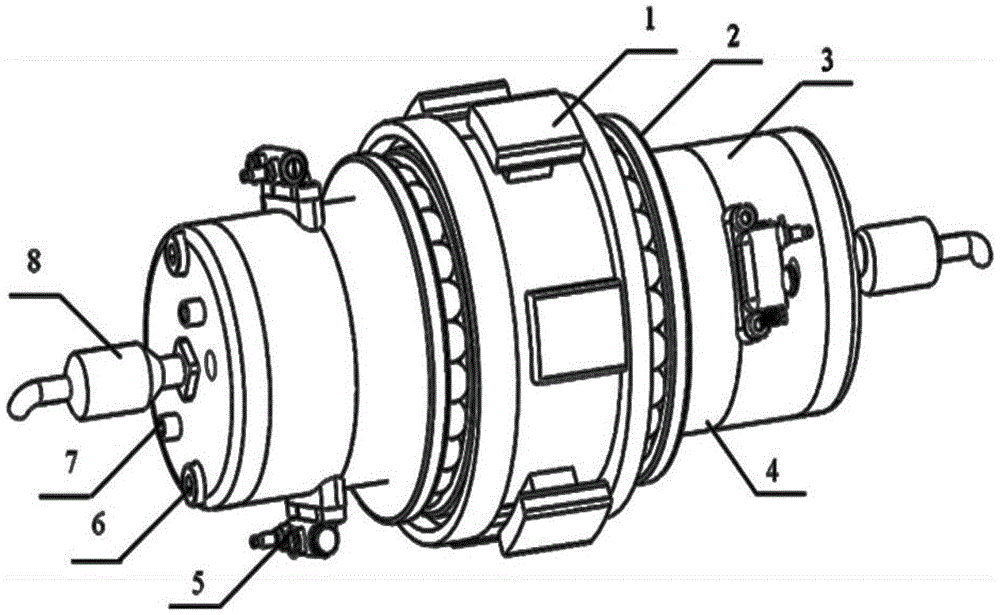

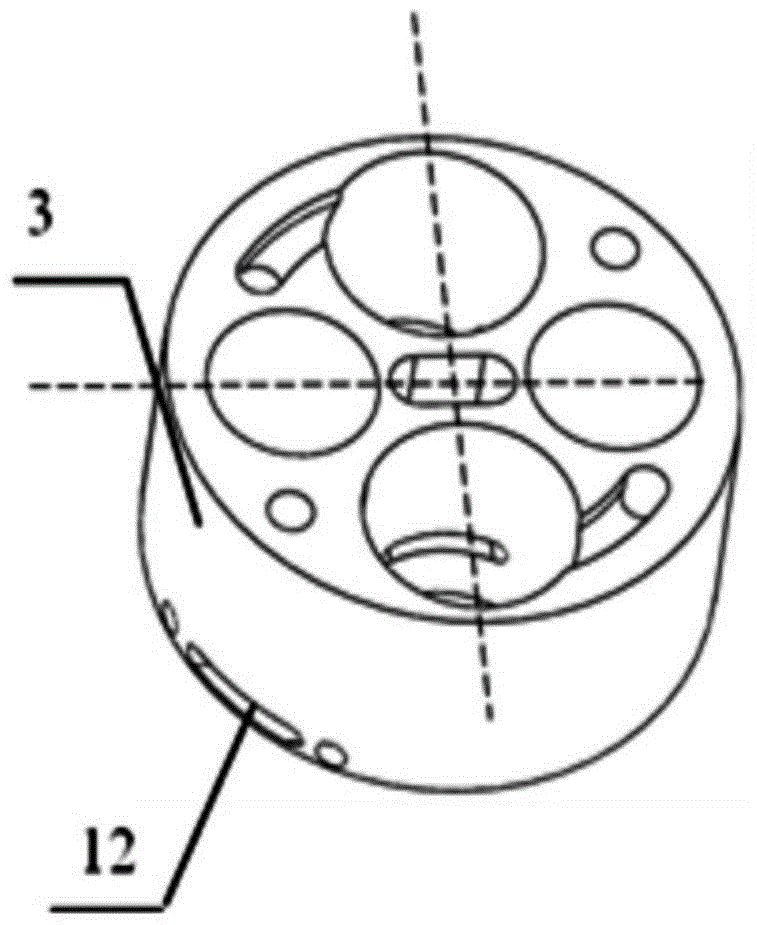

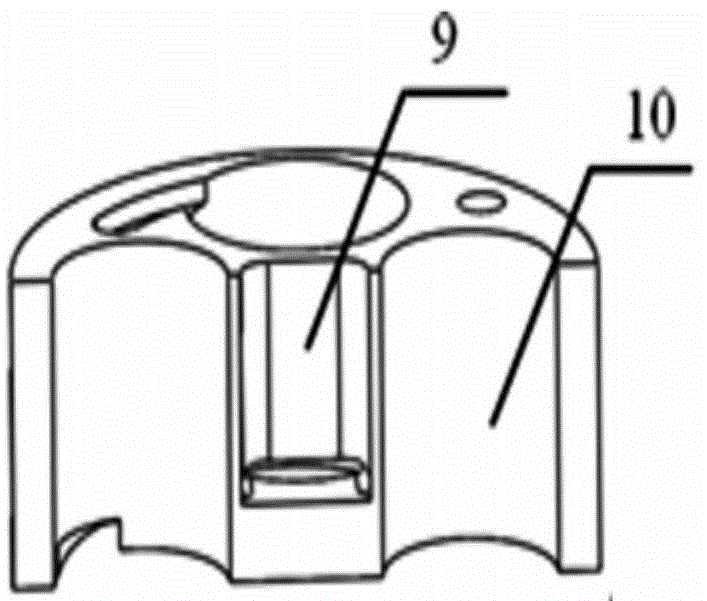

[0039] Such as figure 1 As shown, the micro-miniature thermal power generating device of the present invention includes an engine assembly and a generator rotor 1, the engine assembly is an axial piston type, and a cam (such as an end face cylindrical cam) is used as a main power conversion component to convert the up and down reciprocating motion of the piston into the rotary motion of the cam. The main axis of the axial piston engine is parallel to the cylinder axis arranged in the circumferential direction. It has the advantages of compact structure and high power density. It is more suitable for the power source of the miniaturized mobile power generation device. The generator rotor 1 is directly connected with the cam and is organically combined. The engine assembly adopts an opposed arrangement structure, and the two cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com