Transmission parking pawl actuation assembly

A technology for actuating components and transmissions, applied to vehicle components, brake components, brakes, etc., can solve the problems of increasing complexity, weight cost and packaging size, and increasing the overall performance of the transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

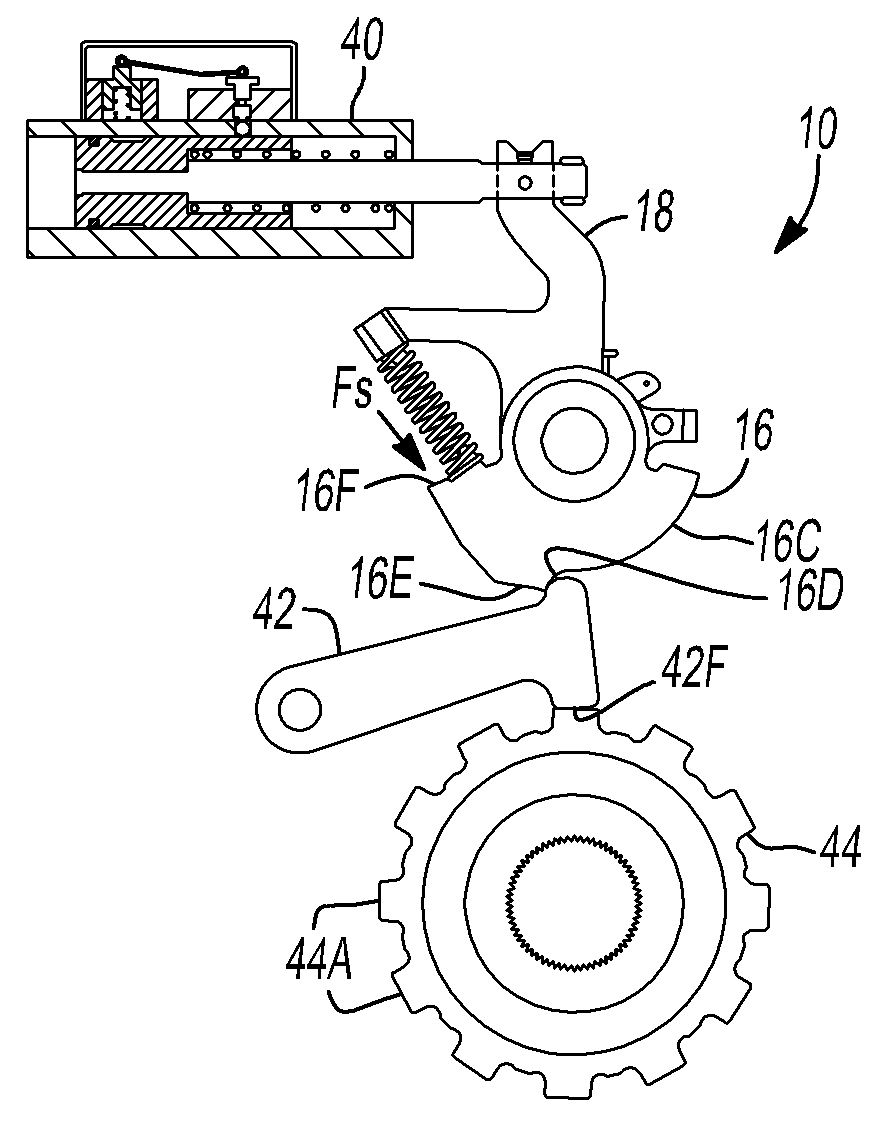

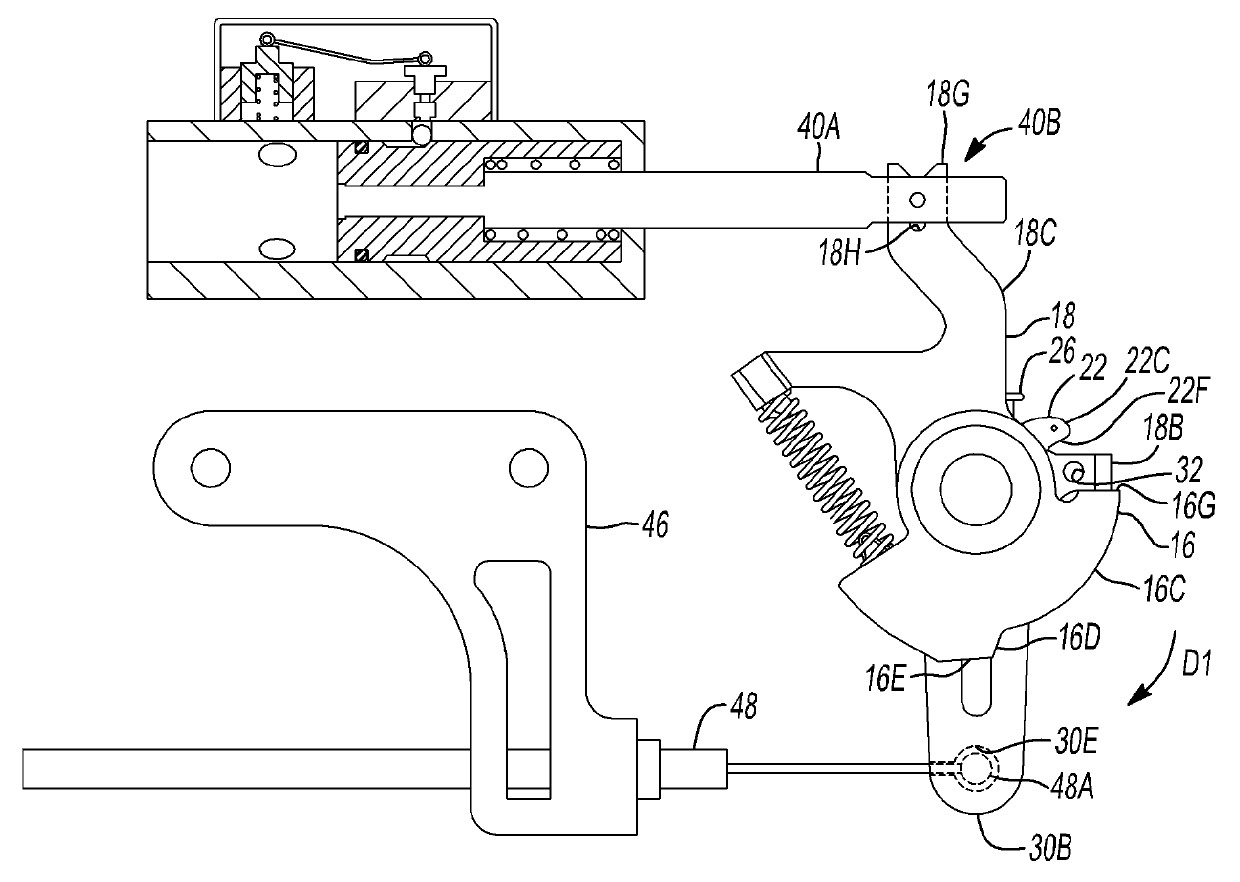

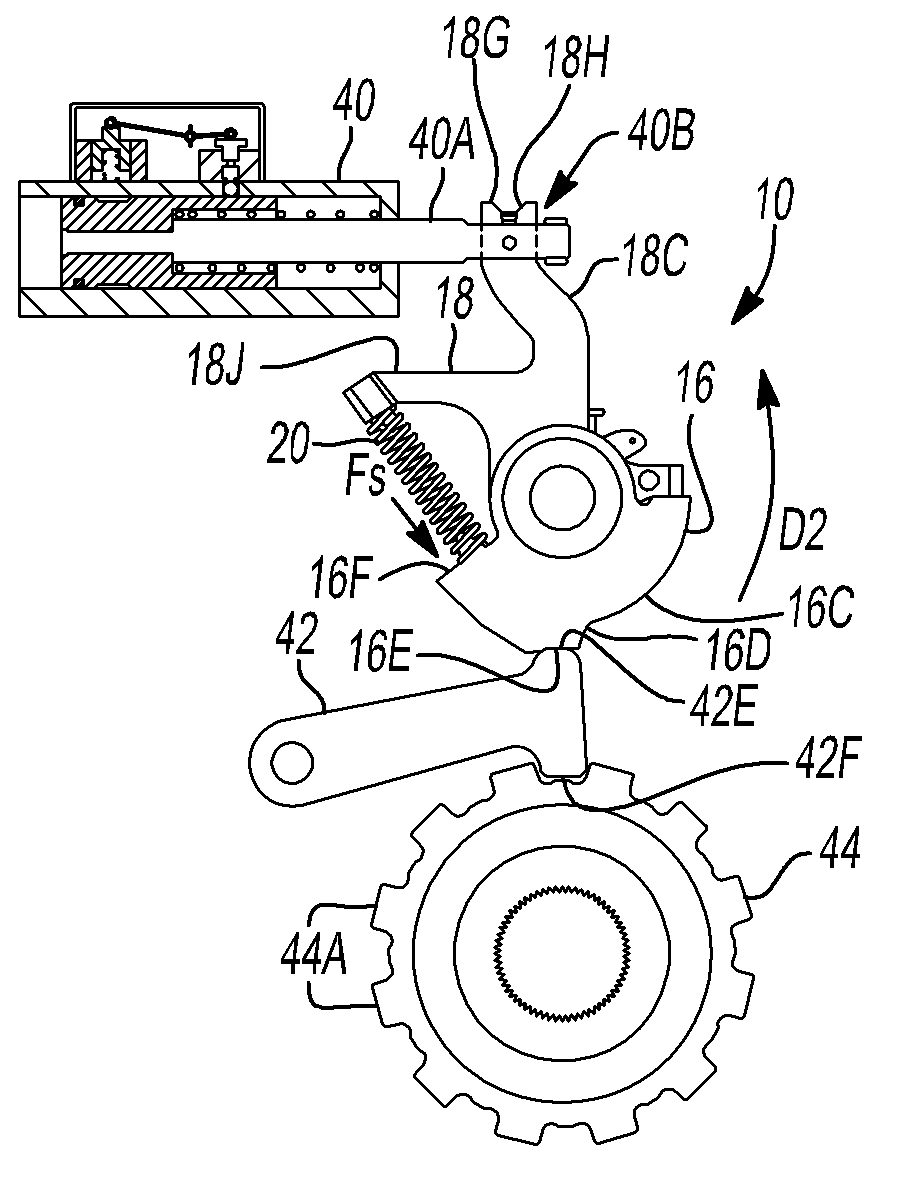

[0100] refer to Figures 1A-1C , a park pawl actuation assembly for a transmission in accordance with the principles of the present invention is generally designated by the reference numeral 10 . The park pawl actuation assembly 10 includes a shaft 12 supported by a transmission housing (not shown), a hub 14, a cam plate 16, a lever plate 18, a compression spring 20, a spring plate 22, a spring 24, first and second Pins 26, 28 and manual release lever 30. More specifically, hub 14 is supported by shaft 12 and is further connected to shaft 12 by pin 26 . The cam plate 16 and the lever plate 18 are rotatably supported by the hub 14 such that the cam plate 16 can move freely relative to the hub 14 and the lever plate 18 . The lever plate 18 is also free to rotate relative to the hub 14 . A compression spring 20 is interposed between the cam plate 16 and the lever plate 18 . The compression spring 20 is arranged to create an angular compressive force between the cam plate 16 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com