Multifunctional testing fixture

A multi-functional, checking tool technology, which is applied in the direction of manufacturing tools, instruments, measuring devices, etc., can solve the problems of narrow use range of checking tools, affecting the accuracy of measurement results, and insufficient uniformity of measurement standards, and achieves simple structure and strong practicability , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

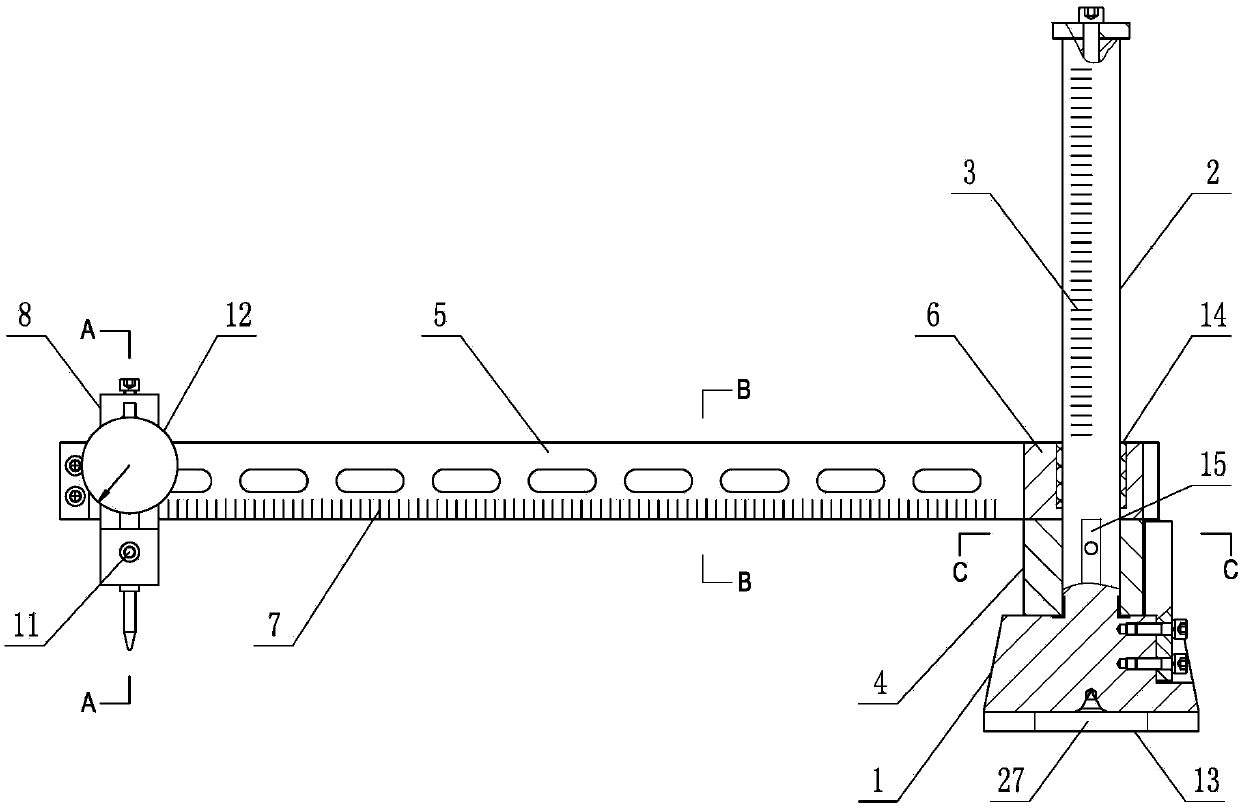

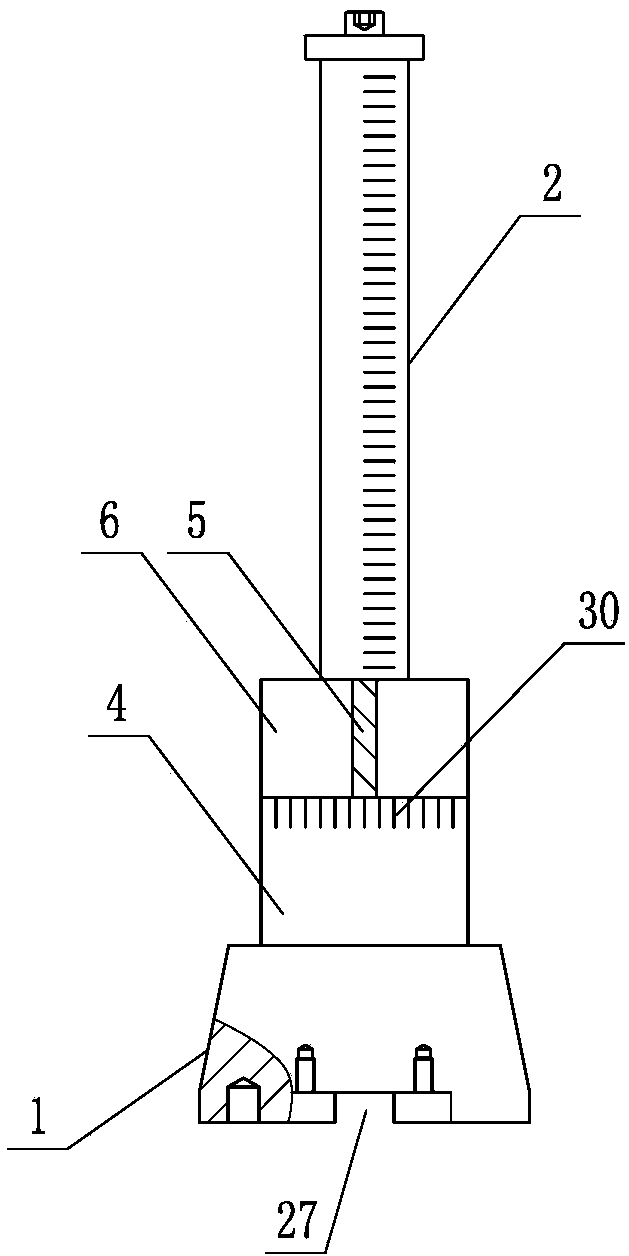

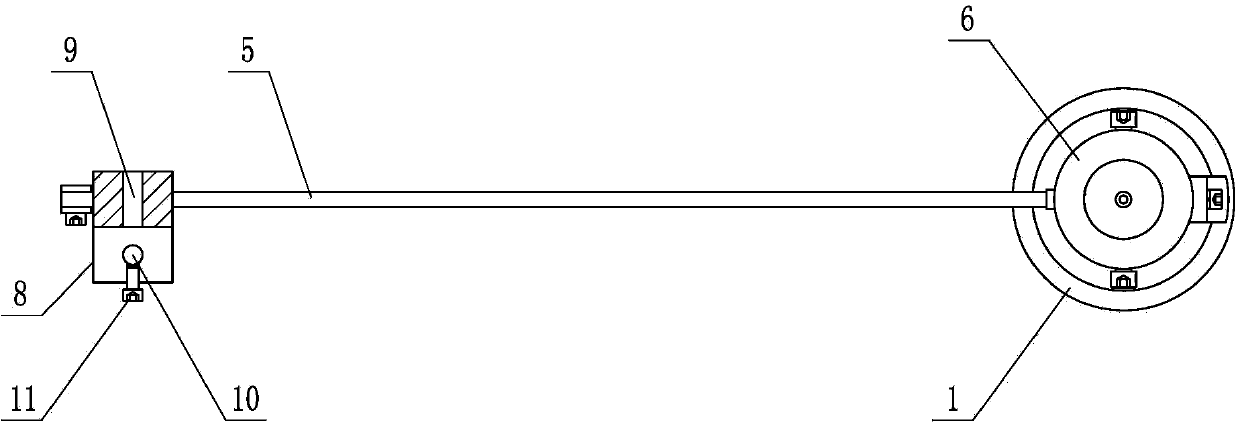

[0025] see figure 1 , image 3 , a kind of multi-functional inspection tool, comprises reference support 1, and the center of described reference support is provided with support guide post 2 vertically, and described support guide post is provided with height scale 3; On described support guide post The lifting bracket 4 is set, and an axial locking mechanism is arranged on the lifting bracket; a rocker guide rod 5 is arranged above the lifting bracket, and one end of the rocker guide rod is hinged with the guide column of the support through a sliding sleeve 6, so that The rocker arm guide rod is provided with a radius scale 7; the rocker arm guide rod is provided with a slide seat 8, and the slide seat is provided with a horizontal positioning hole 9 and a vertical positioning hole 10, and the horizontal positioning hole and the A set screw 11 is arranged on one side of the vertical positioning hole, and a dial indicator 12 is installed on the horizontal positioning hole o...

Embodiment 2

[0034] This embodiment is an improvement made on the basis of Embodiment 1. For the same parts as in Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and no repeated description will be made here.

[0035] see Figure 12 , Figure 13 , in this embodiment, the sliding sleeve 6 of the rocker arm guide rod 5 is provided with an anti-rotation groove 18, and the stop long ruler 19 is fixed on the reference support 1, and the stop long ruler is stuck on the anti-rotation In the turn slot. The bottom of the stop ruler is fixed on the reference support 1 by screws 20, and the stop ruler cooperates with the anti-rotation groove to realize the circumferential fixation of the rocker guide rod, and the slide seat can only move along the rocker arm. The guide rod moves in a straight line. By keeping the rocker arm guide rod parallel to the axis of the workpiece to be measured, the straightness error of the workpiece to be measured can be detected. ...

Embodiment 3

[0039]This embodiment is an improvement made on the basis of Embodiment 1. For the same parts as in Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and no repeated description will be made here.

[0040] see Figure 5 , in the present embodiment, the bottom of the slide seat 8 is provided with a threaded hole, the threaded hole is fixed with a marking cone 22, the tapered rod of the marking cone is provided with an external thread, and the tapered rod of the marking cone is connected to the Threaded hole threaded connection. Also be equipped with backstop nut 23 on the tapered rod of marking cone, the end face of backstop nut is pressed against on the described slide seat. A set screw 24 is arranged on the sliding seat. The set screw can realize the positioning of the sliding seat on the rocker arm guide rod 5 .

[0041] Before drawing concentric circles, first determine the center of the reference circle, draw two straight lines throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com