Device and method for testing elongation and pull-apart of integral rubber track in horizontal state

A technology of rubber track and horizontal state, which is applied in the direction of testing the ductility of materials and testing the strength of materials by applying stable tension/pressure, which can solve the problems of long development cycle, high test cost, and inability to collect test data, etc. Short development cycle, reduce test cost, and ensure the effect of internal force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

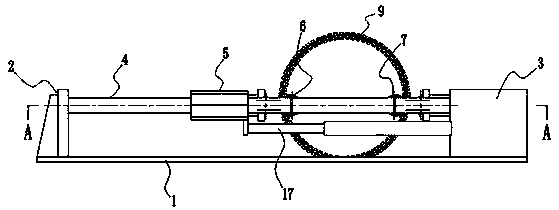

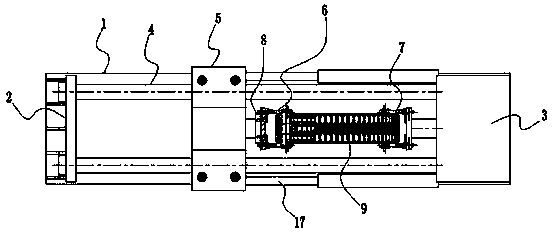

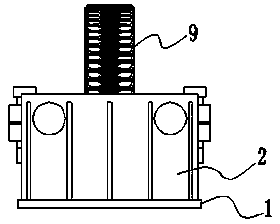

[0049] Embodiment 1: as Figure 1 to Figure 3As shown, an integral rubber track elongation rate and tear-off test device in a horizontal state includes a platform 1, and the integral rubber track elongation rate and tear-off test device in a horizontal state also includes a device arranged on the platform 1 The support 2 on the side, the horizontal loading hydraulic cylinder 3 arranged on the other side of the platform 1, the horizontal support column 4 fixedly arranged between the support 2 and the horizontal loading hydraulic cylinder 3, can be mounted along the horizontal support column 4 Move back and forth and lock the beam box 5 fixed on the horizontal support column 4, the simulated driving wheel device 1 6, the simulated driving wheel device 2 7, the load sensor used to measure the load of the horizontally loaded hydraulic cylinder 3 8. A displacement sensor (not shown in the figure) and a controller (not shown in the figure) used to measure the loading displacement of...

Embodiment 2

[0069] Embodiment 2: as Figure 10 with Figure 11 As shown, compared with Embodiment 1, the difference is that: the beam box 5 includes two boxes, respectively an upper box 51 and a lower box 52, and the beam box 5 also includes a locking screw 53 and lock nut 54; the lock screw 53 passes through the two casings and the lock nut 54 is respectively locked on the two ends of the lock screw 53 passing through the two casings; through the lock nut 54 cooperates with the locking screw 53 so that the two boxes are in contact, so that the two boxes are locked and fixed on the horizontal support column 4, and the parts where the two boxes are in contact are respectively opened There are notch one 15 and notch two 16 , and when the two boxes are in contact, the notch one 15 and notch two 16 form a through hole matching the horizontal support column 4 . When the beam box 5 needs to move along the horizontal support column 4, the lock nut 54 can be unscrewed first, so that the upper b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com