A wrapping knife structure of a fully automatic rotor shredder

A paper shredder, fully automatic technology, applied in the direction of laying solid insulation, etc., can solve the problems that affect the use of the entire rotor, paper warping, time-consuming and labor-intensive problems, reduce labor intensity and production costs, convenient operation, and motor life. The effect of safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

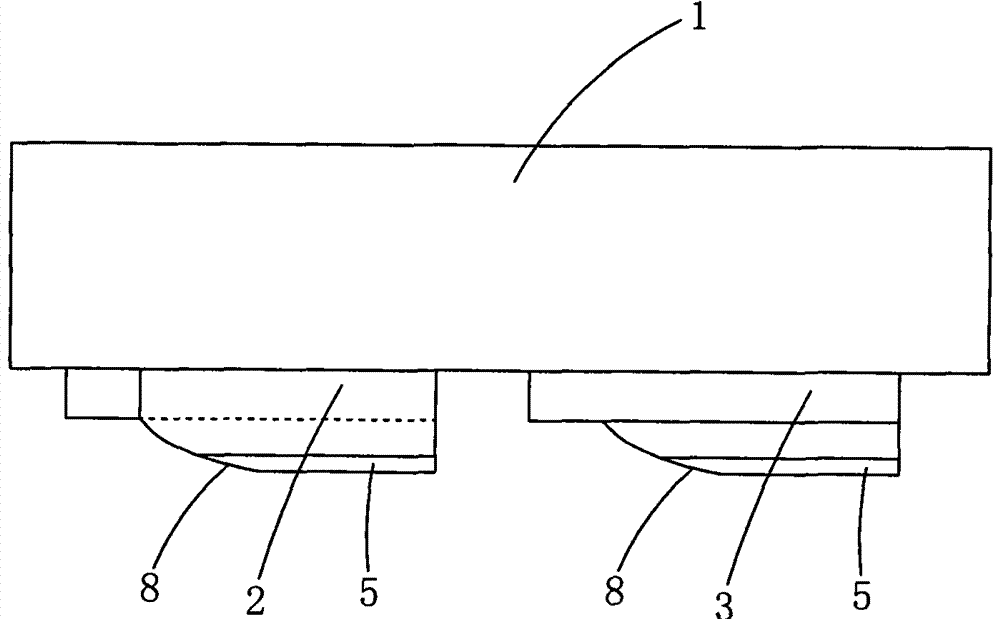

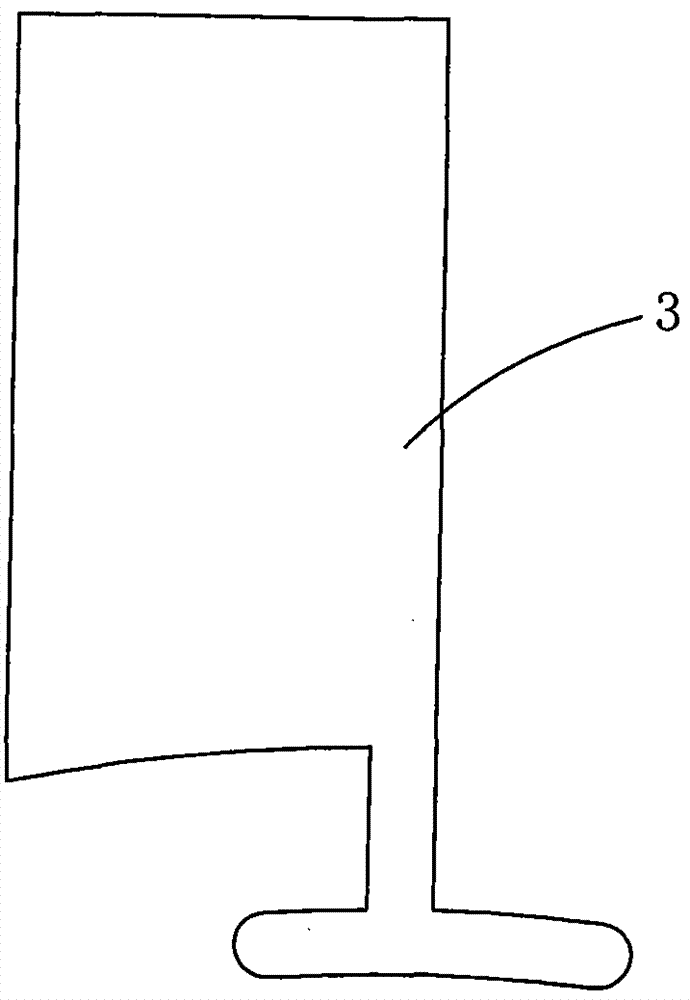

[0014] refer to Figure 1 to Figure 6 According to the embodiment of the present invention, a paper wrapping knife structure of a fully automatic rotor paper shredder includes a paper wrapping knife mounting seat 1, and the paper wrapping knife mounting seat 1 is provided with a front paper wrapping blade 2 and a rear paper wrapping blade 3 , the front paper wrapping blade 2 and the rear paper wrapping blade 3 are respectively provided with a guide slope 4, the guide slope 4 is set in the opposite direction, the guide slope 4 ensures that the insulating paper can accurately enter the rotor core slot, the front paper wrap blade 2 And the back paper wrapping blade 3 is also respectively provided with a paper pressing sheet 5, and the surface of this paper pressing sheet 5 has a wide end 6 and a narrow end 7, and the paper pressing sheet 5 is provided with an inclined from the narrow end 7 end. Wrapping the knife face 8, the paper pressing sheet 5 wraps the scratched insulating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com