Peeling and grain recycling mechanism for corn harvester

A technology of corn harvester and recovery mechanism, which is applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of complex structure and large volume of the machine, and achieve the effect of reducing the volume of the machine and simplifying the structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

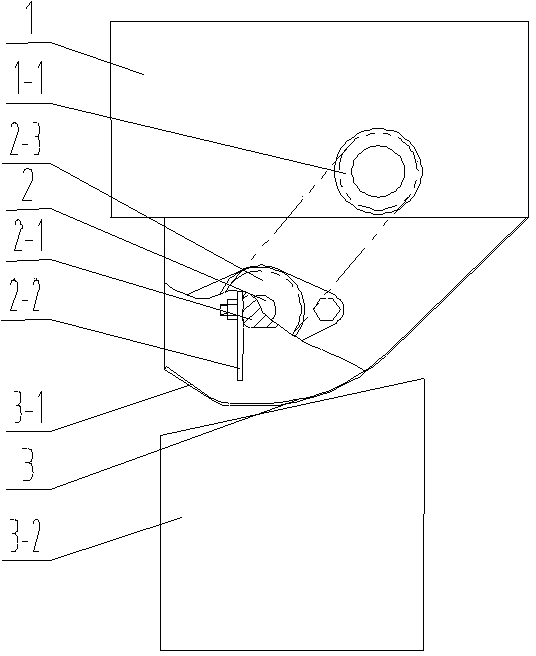

[0013] The detailed description and technical content of the present invention are described as follows in conjunction with the accompanying drawings. However, the accompanying drawings are only provided for reference and description, and are not used to limit the present invention.

[0014] When the corn machine is working, the corn husks and corn kernels peeled off by the peeling machine (1) fall on the grain recovery screen (3-1) installed below, and the power is transmitted from the power output wheel (1-1) to the power input wheel (2-3), drive the agitator shaft (2-1) to rotate, the blade (2-2) installed on the agitator shaft (2-1) throws the corn husks out of the kernel recovery sieve (3-1), and the corn The grains fall into the grain recovery box (3-2) through the grain recovery hole at the bottom of the grain recovery screen (3-1), realizing the function of grain recovery.

[0015] The foregoing descriptions are only preferred embodiments of the present invention, and are n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap