Deepwater net cage with single-point mooring system

A deep-water cage and mooring system technology, applied in fish farming, application, climate change adaptation, etc., can solve the problem that dynamic response cannot meet severe sea conditions, improve typhoon resistance and risk prevention capabilities, and avoid collision and entanglement. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

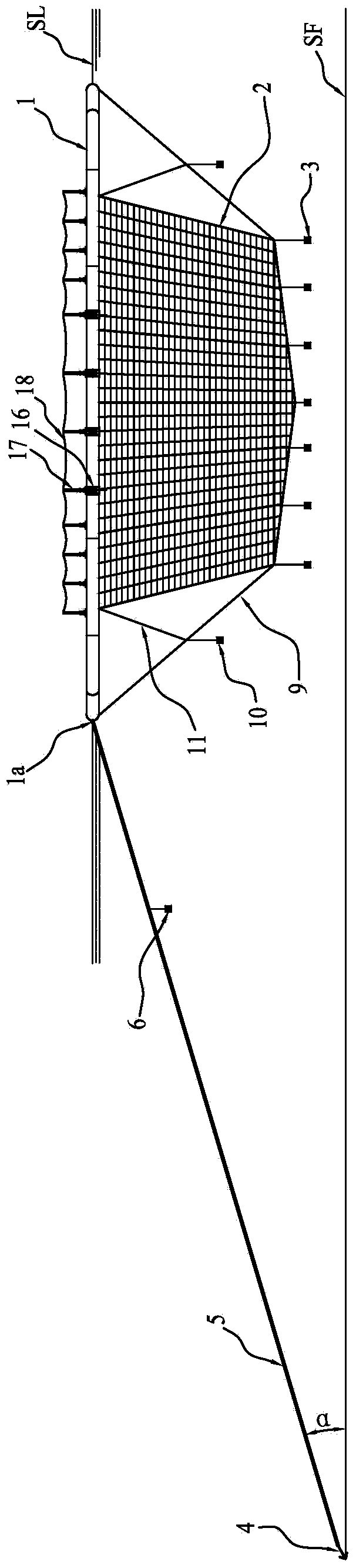

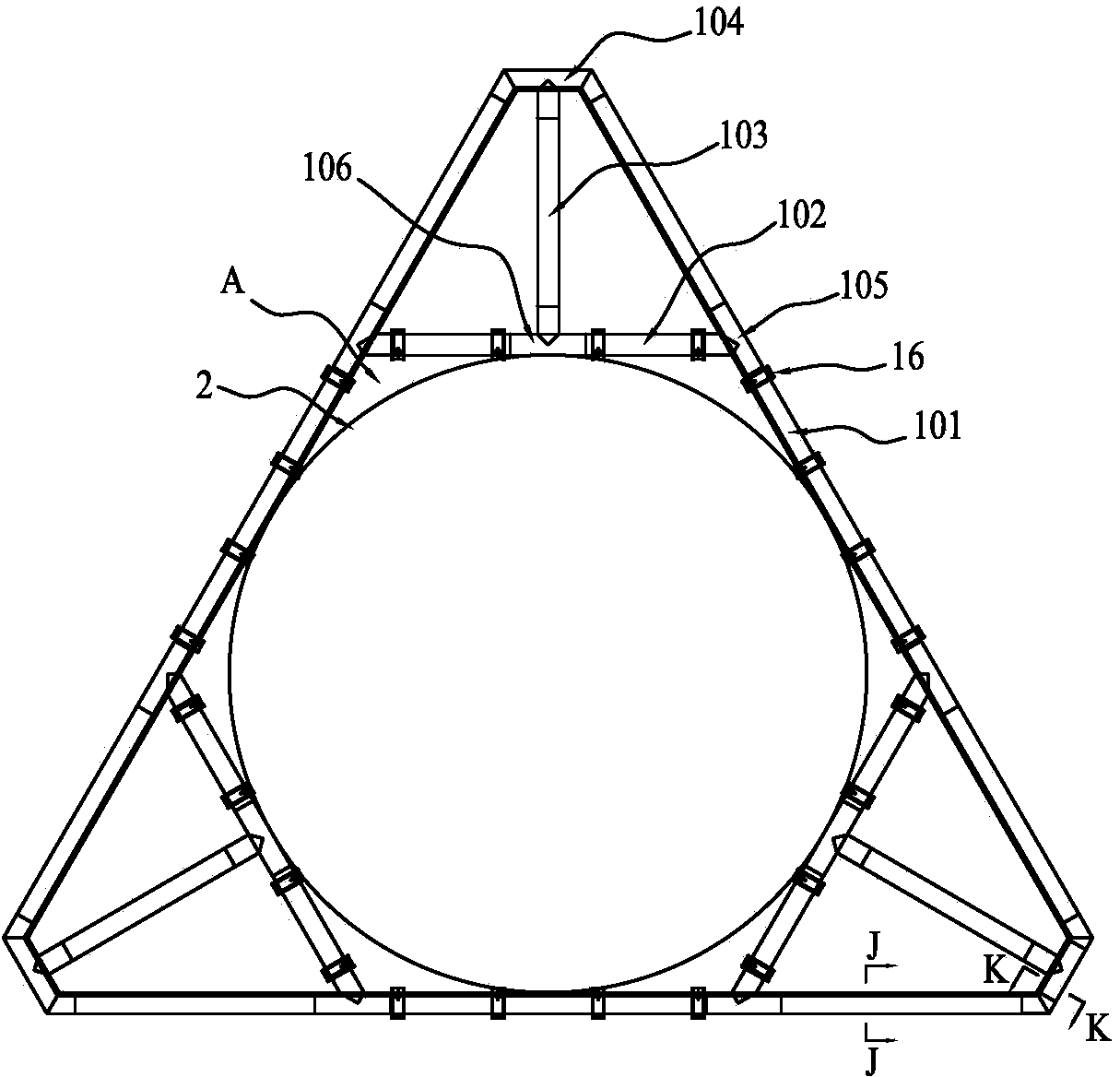

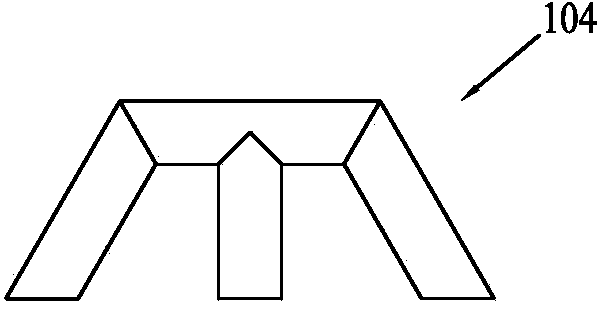

[0038] Such as Figure 1 to Figure 4-2 As shown, the deep-water net cage with the single-point mooring system of Embodiment 1 of the present invention includes a floating pipe frame 1, a net clothing 2 and an anchoring system. The floating pipe frame 1 floats on the sea level SL, and the top of the net clothing 2 is connected to a floating A net weight 3 is hung on the bottom of the pipe frame 1 to form a space for seawater cultivation.

[0039] The mooring system of the first embodiment includes an anchor 4, an anchor rope 5 and an anchor rope weight 6; the floating pipe frame 1 is provided with a mooring point 1a, the anchor 4 sinks into the seabed SF, and the lower end of the anchor rope 5 is connected to the anchor 4, The upper end is connected to the mooring box point 1a, and the rope length of the anchor rope 5 is such that the anchor rope 5 forms an angle α of 25° with the sea level SL in a tight state; the anchor rope weight 6 is hung on the anchor rope 5, and the anch...

Embodiment 2

[0059] Such as Figure 7 Shown, the deep-water net cage of embodiment two of the present invention is substantially the same as embodiment one, and their difference is: in the present embodiment two, the mooring system of deep-water net cage also comprises floater 7 and float cable 8; The upper end is connected to the mooring point 1a by the buoy 7 and the buoy cable 8, that is: the upper end of the anchor rope 5 and one end of the buoy cable 8 are respectively connected to the buoy 7, and the other end of the buoy cable 8 is connected to the mooring point 1a, and the buoy 7 floats in the sea. on the plane SL. The working principle of the second embodiment is basically the same as that of the first embodiment, and the increase of the float 7 and the float cable 8 can further buffer the instantaneous stress of the deep-water net cage and improve the stability of the deep-water net cage.

Embodiment 3

[0061] The deep-water cage of the third embodiment of the present invention can adopt any one of the construction methods described in the first or second embodiment. The difference is that in the third embodiment, the length of the anchor rope 5 is such that the anchor rope 5 is In the tense state, it forms an angle α of 17° with the sea level SL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com