Press-down type centerless grinding machine

A centerless grinding machine and down-pressing technology, which is applied in the field of parts processing, can solve the problems of affecting the processing accuracy and surface smoothness, easy to produce deviation, and not stable enough, so as to improve the grinding accuracy and surface smoothness, and increase the grinding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

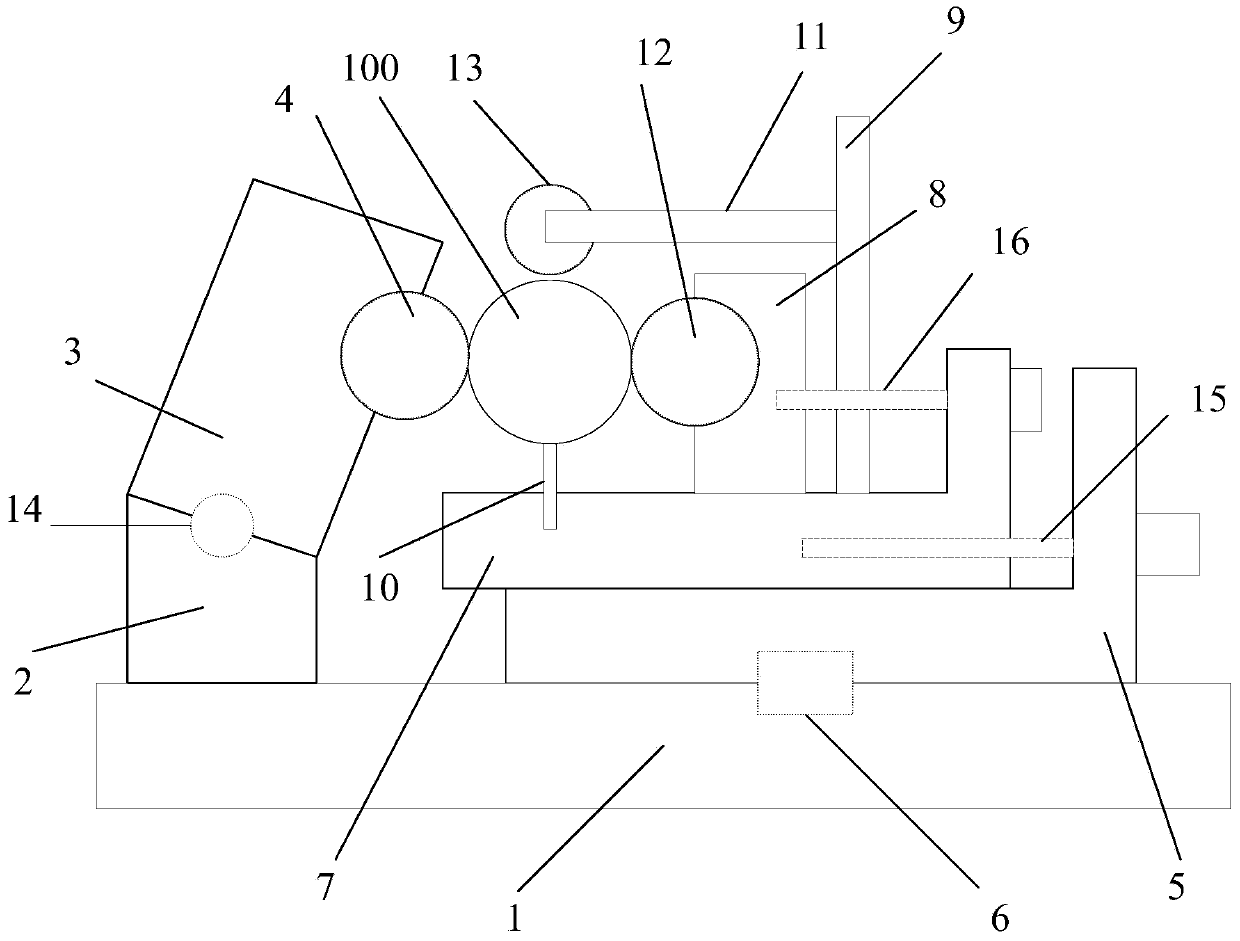

[0020] The present invention proposes a press type centerless grinder, such as figure 1 As shown, it includes: base 1, support seat 2, first support 3, first grinding wheel 4, rotating platform 5, rotating shaft 6, sliding platform 7, second support 8, third support 9, workpiece support 10, support Rod 11 , second grinding wheel 12 , adjustment wheel 13 , first adjustment screw 14 , second adjustment screw 15 and third adjustment screw 16 .

[0021] The support base 2 is mounted on the base 1 , the first bracket 3 is slidably installed on the support base 2 , and the first bracket 3 is connected with a first adjusting screw 14 for adjusting its position on the support base 2 . The first grinding wheel 4 is installed on the first support 3 for grinding the workpiece.

[0022] The rotating platform 5 is horizontally rotatably mounted on the base 1 via a rotating shaft 6 .

[0023] The sliding platform 7 is slidably installed on the rotating platform 5 , and the sliding platfor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap