A concrete vacuum suction device

A vacuum water absorption and concrete technology, which is applied in the direction of ceramic molding mandrel, ceramic molding machine, manufacturing tools, etc., can solve the problems of shortening the service life of the vacuum machine, damage of the vacuum machine, and large fluctuation of vacuum degree, so as to reduce production costs and absorb water. The effect of shortening the time and reducing the fluctuation of the vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

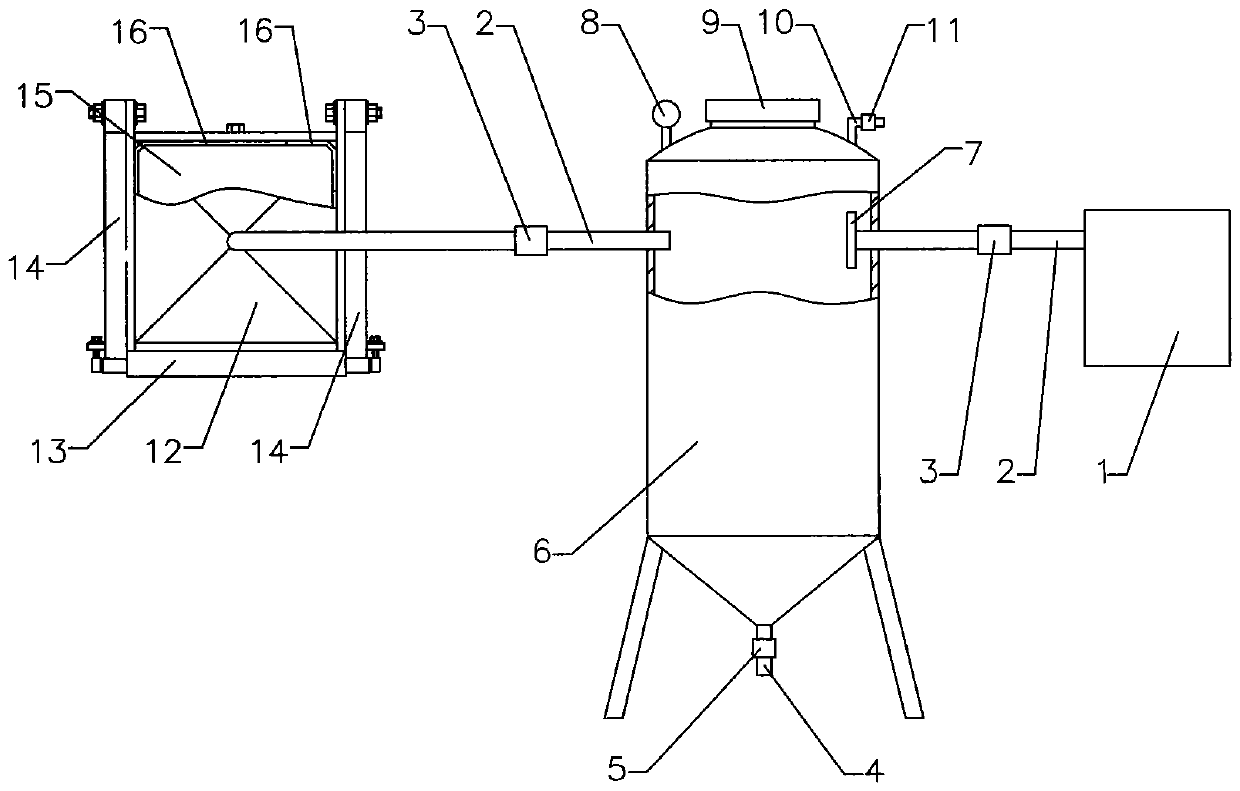

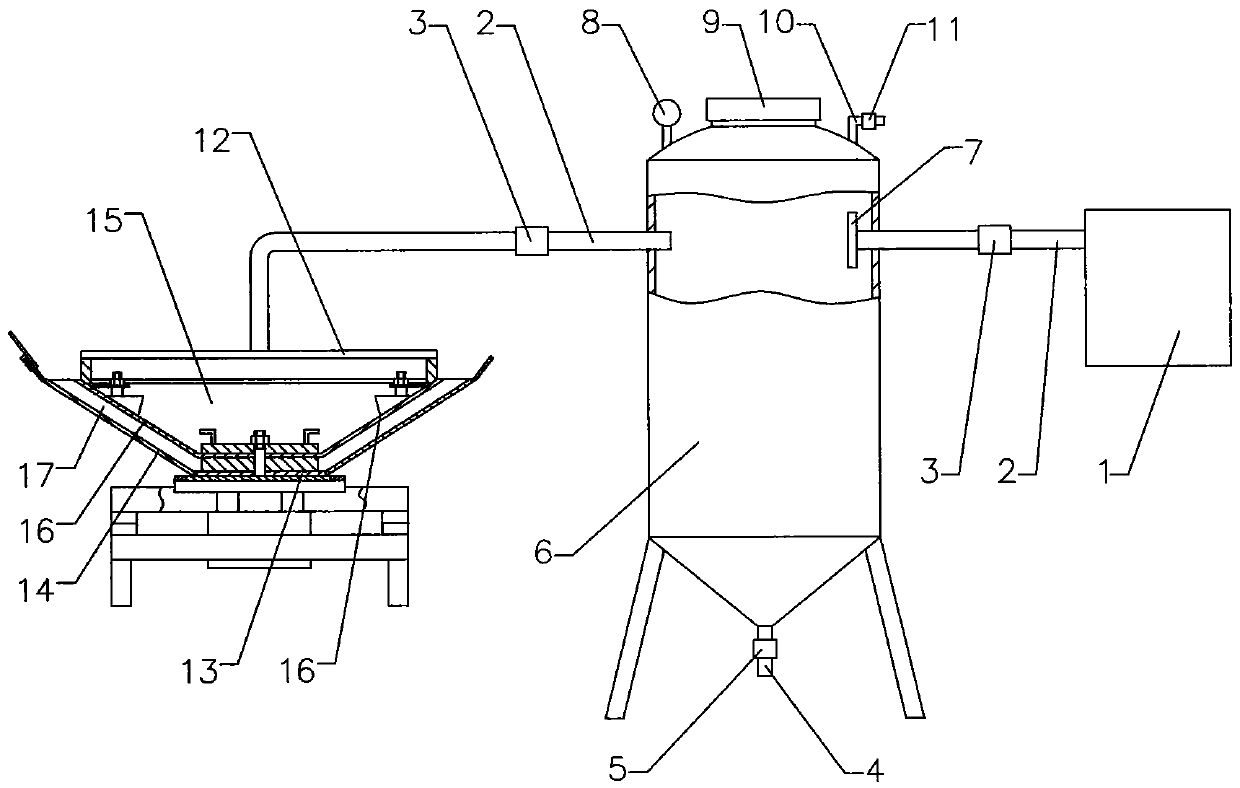

[0046] Example 1: as attached figure 1 As shown, a concrete vacuum suction device includes a vacuum tank 6, a plurality of connecting pipes 2 are arranged on the vacuum tank 6, at least one connecting pipe 2 is connected with a vacuum machine 1, and / or in the vacuum tank 6 on the connecting pipe 2 A filter device is provided, through which sewage, sundries, cement thin materials, etc. are effectively prevented from entering the vacuum machine 1, and the vacuum machine 1 is effectively protected.

[0047] In this embodiment, only a schematic structural diagram of the connection between one connecting pipe 2 and the vacuum machine 1 is shown, and a plurality of connecting pipes 2 can be connected between the vacuum tank 6 and the vacuum machine 1 as required.

[0048] The filter device is a filter screen 7, a filter cloth or a filter cotton. In this embodiment, a filter screen 7 is used, which can be replaced with a filter cloth or filter cotton as required, or a filter plate, w...

Embodiment 2

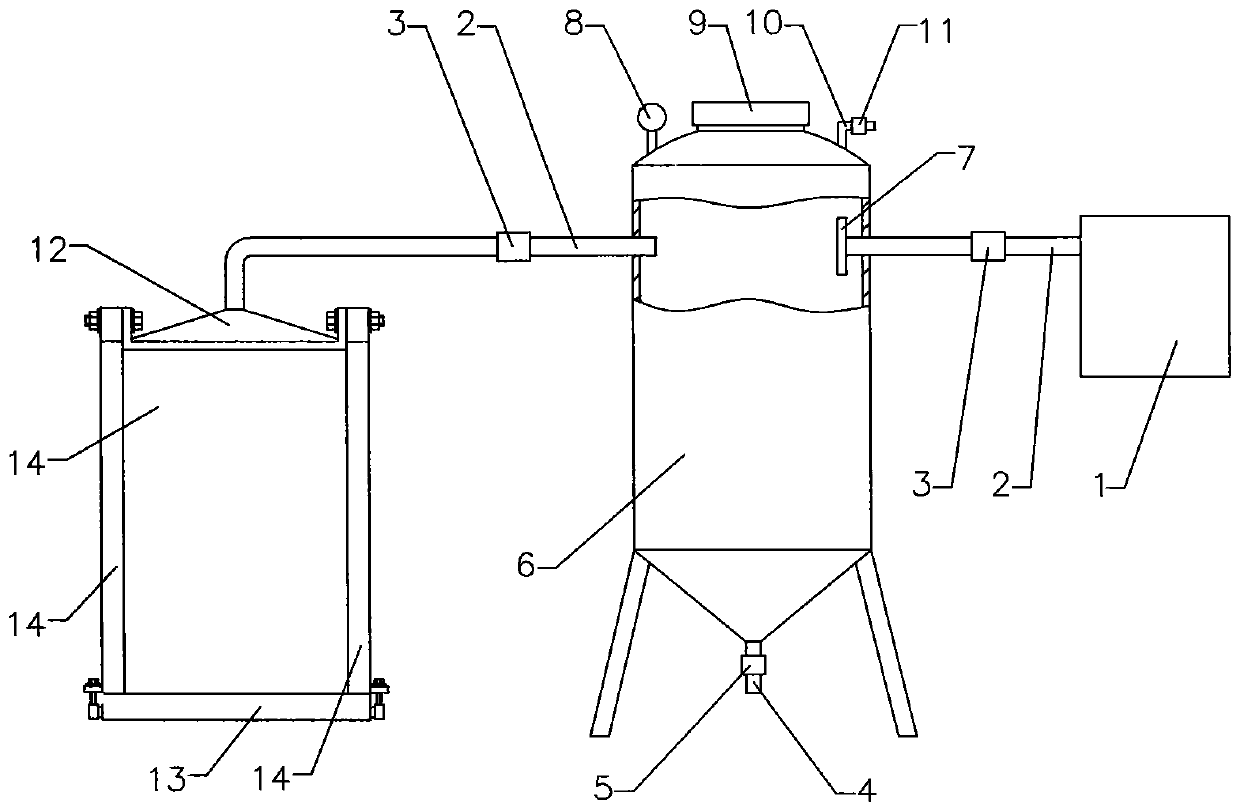

[0069] Example 2: as attached figure 2 As shown, the mold connected to the vacuum tank 6 is a vertical mold.

[0070] The other structures are the same as in Example 1.

Embodiment 3

[0071] Example 3: as attached figure 1 As shown, a concrete vacuum suction device includes a vacuum tank 6, a plurality of connecting pipes 2 are arranged on the vacuum tank 6, at least one connecting pipe 2 is connected with a vacuum machine 1, and / or in the vacuum tank 6 on the connecting pipe 2 A filter device is provided, through which sewage, sundries, cement thin materials, etc. are effectively prevented from entering the vacuum machine 1, and the vacuum machine 1 is effectively protected.

[0072] In this embodiment, only a schematic structural diagram of the connection between one connecting pipe 2 and the vacuum machine 1 is shown, and a plurality of connecting pipes 2 can be connected between the vacuum tank 6 and the vacuum machine 1 as required.

[0073] The filter device is a filter screen 7, a filter cloth or a filter cotton. In this embodiment, a filter screen 7 is used, which can be replaced with a filter cloth or filter cotton as required, or a filter plate, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com