Thermal insulation wired glass

A technology of wired glass and flat glass, which is applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., which can solve the problems of poor safety, easy breakage, and poor thermal insulation effect, and achieve the goal of using High safety, good heat insulation performance, not easy to break

Inactive Publication Date: 2014-12-10

张玉芬

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most of the glass widely used by people is single-layer flat glass, which has good light transmission, but its thermal insulation effect is poor, and it cannot effectively block the heat of outdoor sunlight from entering the room, resulting in high indoor temperature and its strength. Poor, easy to break when impacted, less safe to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

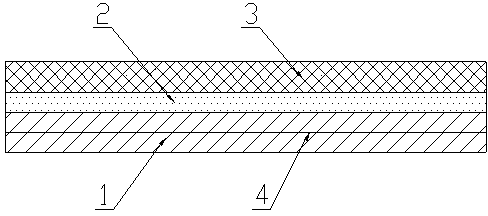

[0013] see figure 1 , a kind of heat-insulating wired glass of the present invention, it comprises flat glass 1, and described flat glass 1 surface is provided with heat-insulating PVB film layer 2, and described heat-insulating PVB film layer 2 is provided with heat-insulating coating layer 3, so A wire mesh 4 is arranged inside the flat glass 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to glass and in particular relates to thermal insulation wired glass. The thermal insulation wired glass comprises sheet glass (1), wherein a thermal insulation PVB film layer (2) is arranged on the surface of the sheet glass (1); a thermal insulation coating layer (3) is arranged on the thermal insulation PVB film layer (2); and a wire mesh (4) is arranged inside the sheet glass (1). The thermal insulation wired glass disclosed by the invention has high thermal insulation property, can effectively shield sunlight so as to keep a shady and cool indoor space, is high in strength and unlikely to break when being impacted, and is high in using safety.

Description

technical field [0001] The invention relates to a glass, in particular to a heat-insulating wire glass. Background technique [0002] Glass is a transparent semi-solid and semi-liquid substance that forms a continuous network structure when molten, and is a silicate non-metallic material that gradually increases in viscosity and hardens during cooling. The main component of ordinary glass is silicon dioxide, which has high chemical stability, thermal stability and good transparency, so it is widely used in various fields. At present, most of the glass widely used by people is single-layer flat glass, which has good light transmission, but its thermal insulation effect is poor, and it cannot effectively block the heat of outdoor sunlight from entering the room, resulting in high indoor temperature and its strength. Poor, easy to break when impacted, and less safe to use. Contents of the invention [0003] The purpose of the present invention is to overcome the above disad...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B3/12B32B15/02B32B15/04B32B17/06B32B33/00B32B7/10

Inventor 张玉芬

Owner 张玉芬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com