Head belt unfolding device with belt sway switches

A technology of deviation switch and display belt, which is applied in the direction of conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems of inability to open, inaccessible, incapable of alarm and parking, and achieve the effect of preventing vicious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

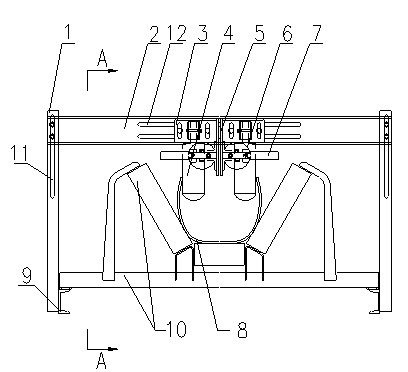

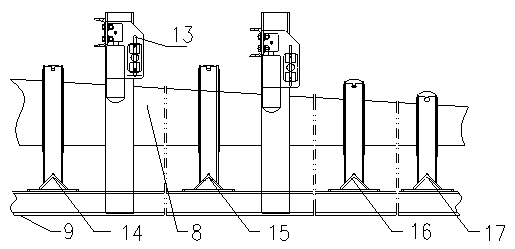

[0027] Example 1: The vertical height or horizontal width can be adjusted through the combination of long holes and bolts to ensure that all parts are in the best position when in use, so that the unwinding roller group is close to the conveyor belt. When the conveyor belt deviates, the conveyor belt will The side will touch the stop roller of the deviation switch, and push the stop roller to rotate, and send out an alarm and stop signal.

[0028] No. 1 long hole 11 is established on the upper end of pole 1, and the end of door beam 2 passes through No. 1 long hole 11 by bolt and is fixed, and the height of door beam 2 is adjusted by the position of bolt and No. 1 long hole 11. The No. 1 long hole on the poles on both sides is connected with the door beam. According to the different belt surface heights of the conveyor belt at different groove angles, adjust the height of the unwinding roller and the deviation switch to ensure that the unwinding roller can be inserted into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com