Copper row chain cleaner of wire cutting machine

A copper chain and cleaning machine technology, applied in the direction of cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of labor-intensive, time-consuming, poor cleaning effect, etc., to improve labor efficiency, facilitate maintenance work, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

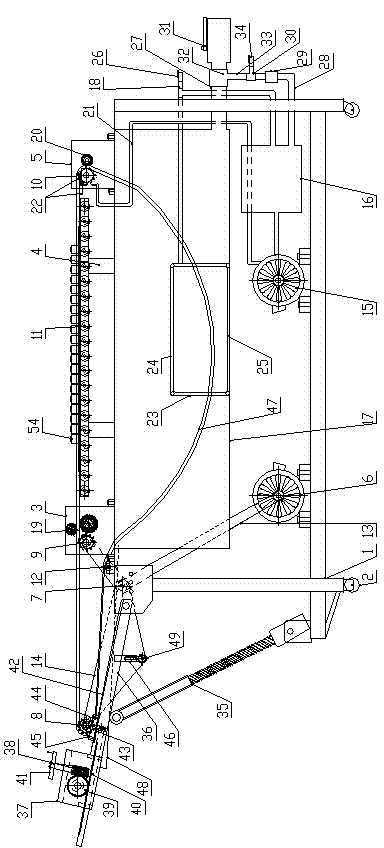

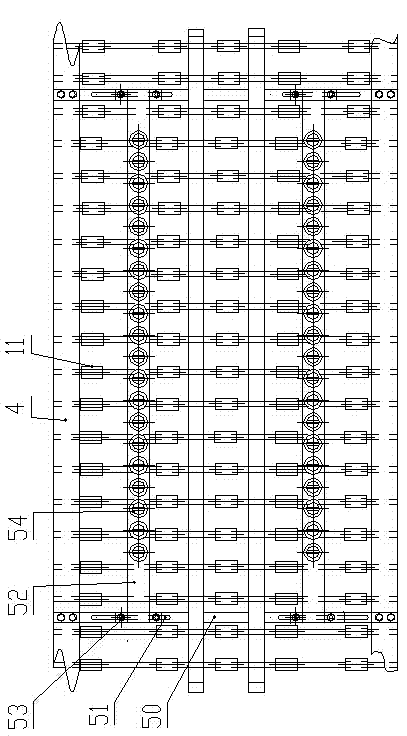

[0028] Such as figure 1 and figure 2 As shown, the wire cutting machine copper row chain cleaning machine of the present invention includes a frame 1, a universal wheel 2 is arranged under the frame 1, and a power transmission mechanism, a cleaning device, and a copper row chain length adjustment mechanism are arranged on the frame 1 And copper bar chain width adjustment mechanism.

[0029] The power transmission mechanism includes front bracket 3, middle bracket 4, rear bracket 5, motor 6, transmission sprocket group 7, tension idler 8, driving idler 9, driven idler 10, idler group 11 and support idler 12. The motor 6 is set on the front side of the lower part of the frame 1, the front support 3, the middle support 4 and the rear support 5 are respectively set on the front side, the middle part and the rear side of the top of the frame 1, and the driving roller 9 is set on the front support 3, The idler group 11 is set on the middle bracket 4, the driven idler 10 is set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com