Novel technology for continuous pneumatic conveying of powder materials

A powder material, pneumatic conveying technology, applied in the direction of conveyor, conveying bulk material, transportation and packaging, etc., can solve the problems of automatic adjustment of valve operation frequency, inability to achieve continuous material conveying, complex control system, etc., to reduce Equipment investment and operating costs, the effect of reducing equipment investment and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

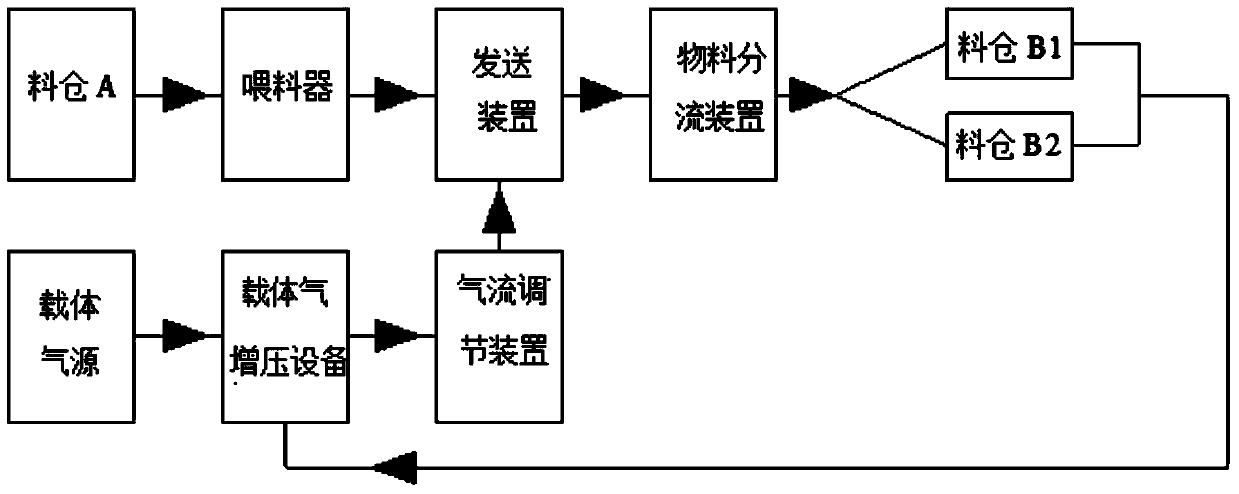

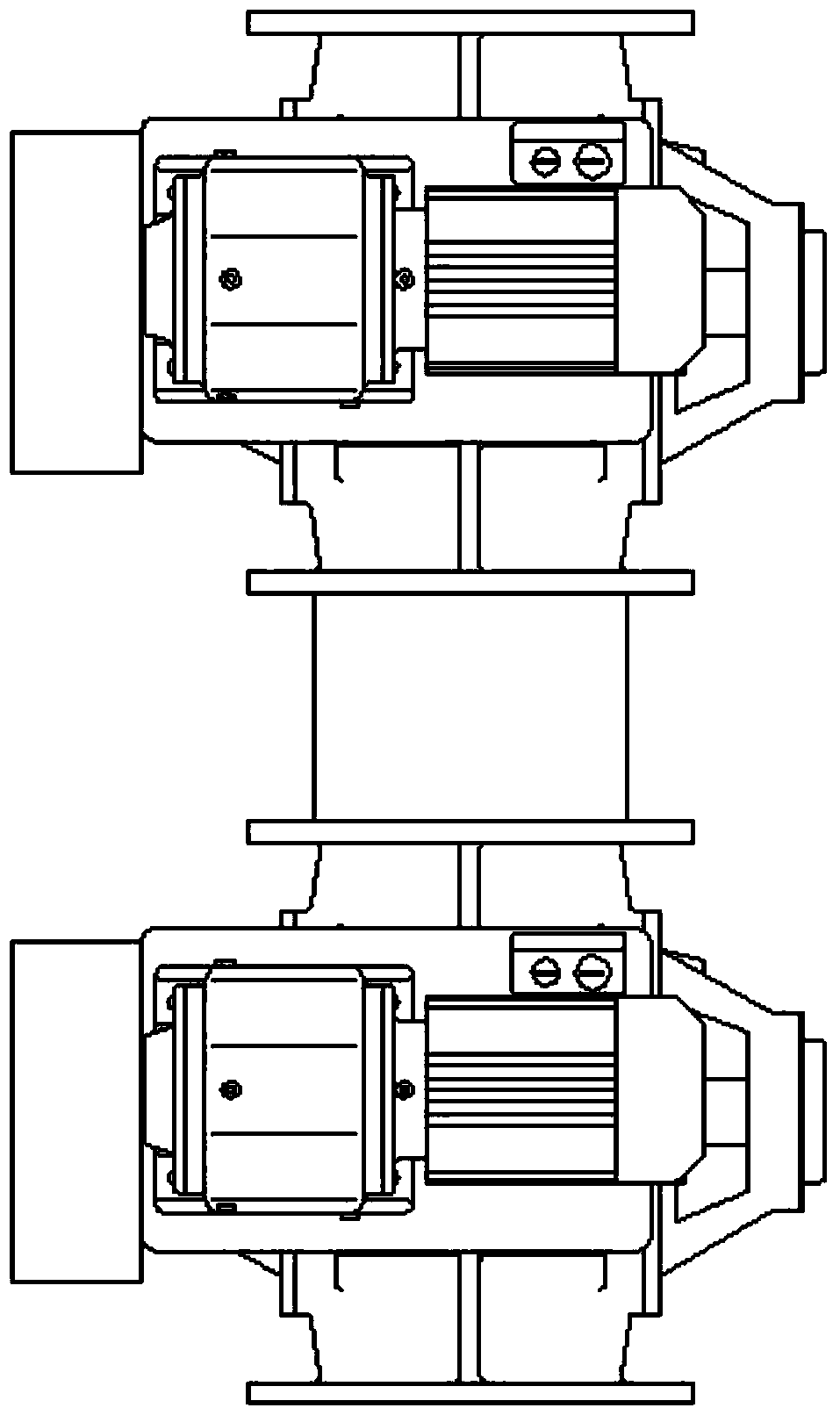

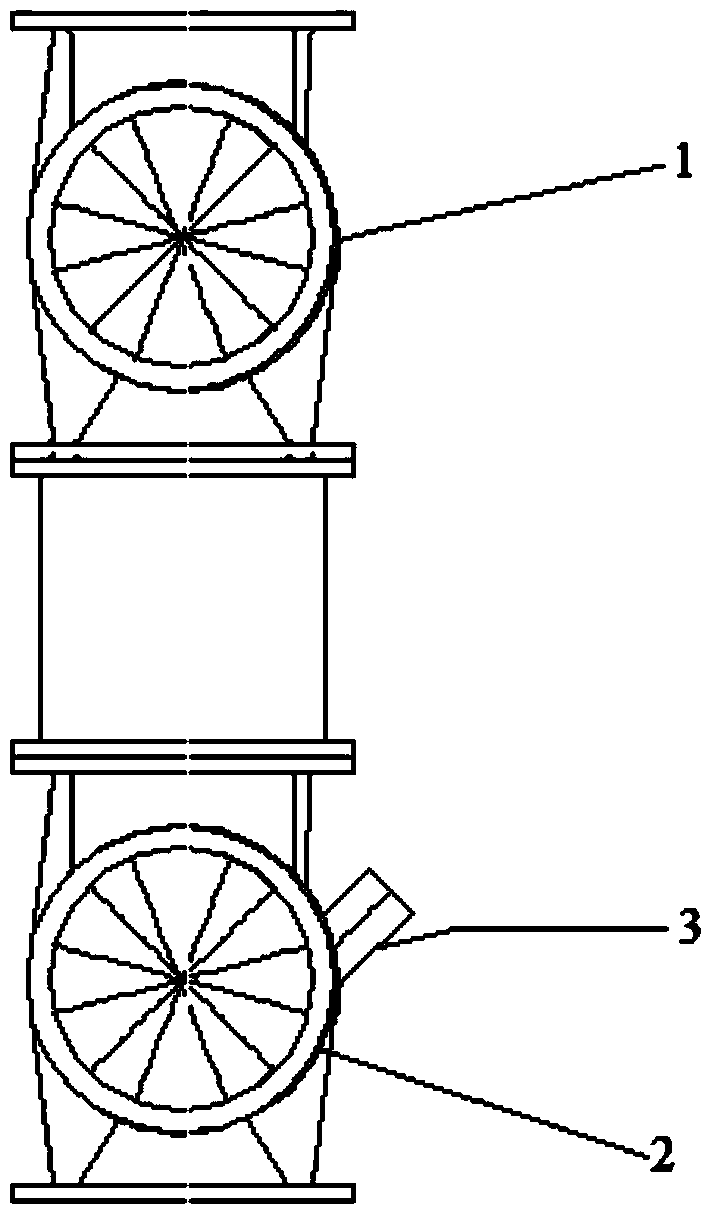

[0022] A new technology for continuous pneumatic conveying of powder materials, such as Figure 1-5 As shown, the easily oxidizable powder material from silo A is transported to the material delivery device after passing through the feeder, and the nitrogen gas output from the nitrogen source is pressurized by 0.35 MPa through the carrier gas booster device, and then passed through the airflow adjustment device and the powder material At the same time, it enters the sending device. In the sending device, the powder material is transported to the material splitting device by nitrogen gas and then sent to different receiving bins B1 and B2 respectively. The nitrogen gas is discharged from the top of the receiving bin B1 and B2 and enters the carrier gas booster. Pressurize the equipment and return it to the system.

[0023] The powder material enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com