Submerged membrane separation device and its operating method

A submerged, separation membrane technology, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., to achieve the effect of reducing operating power consumption and controlling membrane pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

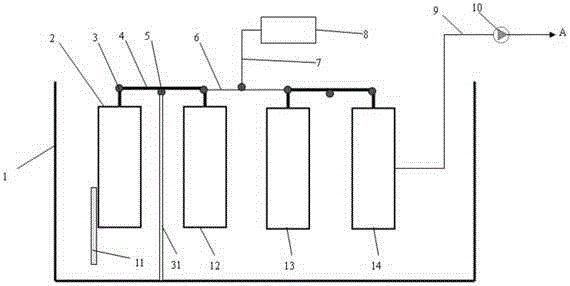

[0019] Embodiment one, such as figure 1 Shown:

[0020] Membrane units 2, 12, 13, 14 are respectively arranged on the positioning guide rails 11 perpendicular to the liquid surface of the water tank, and immersed in the water tank 1. The two cantilever ends of the balance bar 4 are connected to the membrane unit through the rotatable connector 3. 2 and the membrane unit 12 are connected to form a balance group, and 5 is the gravity balance fulcrum of the balance bar; the same balance bar is used to connect the membrane unit 13 and the membrane unit 14 to form another balance group; the two balance groups pass through the linkage rod 6 and the traction Steel rope 7 and traction motor 8 form a linkage group. The balance bar 4 or the linkage bar 6 is connected with the support 31 vertically erected and fixed in the water tank through the gravity balance fulcrum 5 .

[0021] The produced water is pumped out by the produced water pump 10 through the produced water pipe 9 . The s...

Embodiment 2

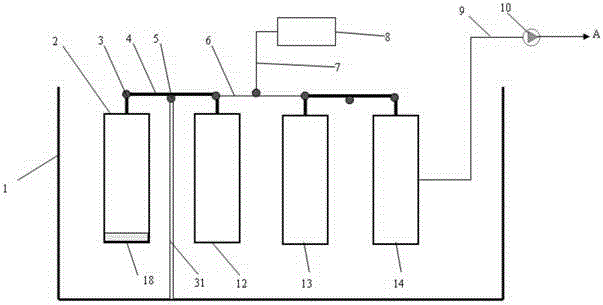

[0024] Embodiment two, such as figure 2 Shown:

[0025] The bottom ends 18 of the membrane units 2, 12, 13, 14 are fixed on the bottom of the water tank 1, and the upper sides of the membrane units 2, 12, 13, 14 are respectively slidably positioned on the positioning guide rails vertically erected in the water tank. The upper part is pulled and lifted by the traction motor, and other operating modes are the same as in Embodiment 1, such as figure 1 shown. In this way, as the upper end of the hollow fiber membranes in the membrane units 2, 12, 13, 14 is pulled up and down by the traction motor, the membranes change periodically from nearly stretching to bending, and the hollow fiber membranes can also be bent. Mechanical scour occurs between the filament and the water body, thereby preventing the accumulation of pollutants on the surface of the hollow fiber membrane and between the filaments of the hollow fiber membrane.

[0026] The content not described in the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com