Modified peanut shell cationic adsorbent, preparation method and application

A cationic, peanut shell technology, applied in the field of environment and chemistry, can solve problems such as unreported, and achieve the effects of low cost, good pollution control effect, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

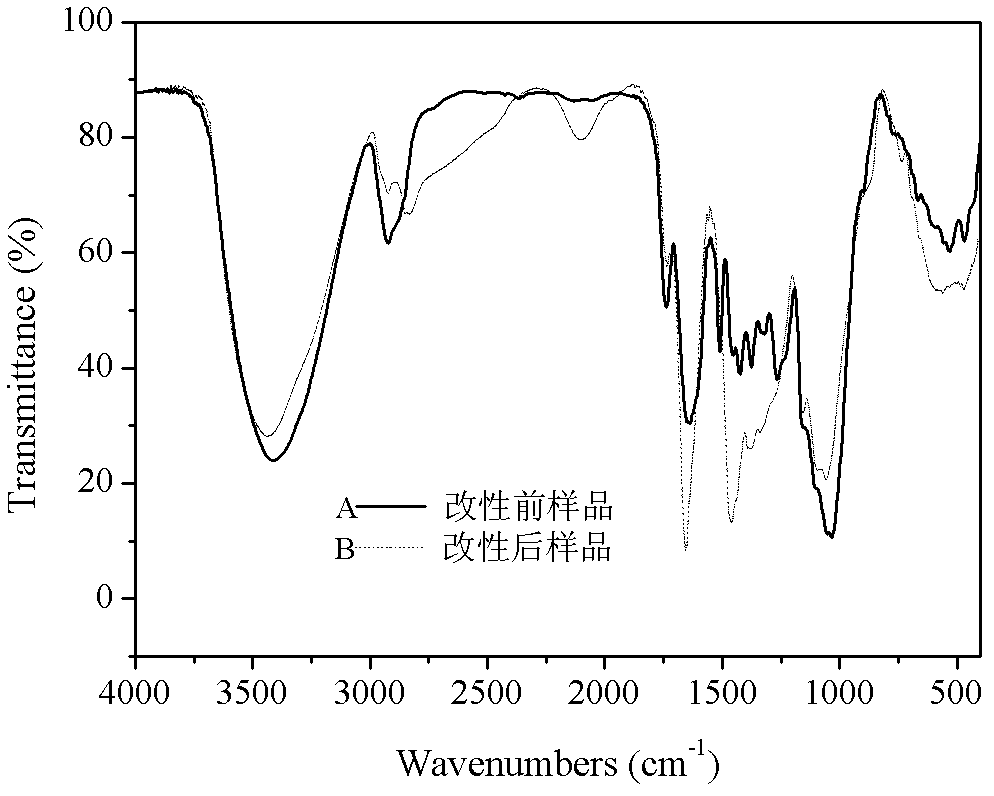

[0030] (1) Peanut shells are crushed to a powder below 1mm by a grinder, weigh 4g of crushed peanut shells into a three-neck round bottom flask, add 10mL epichlorohydrin and 10mL DMF, and place in a constant temperature water bath at 85°C to stir and react 1 hour.

[0031] (2) 4 mL of triethylenetetramine was added dropwise to the reactant in step (1), and stirred and reacted in a constant temperature water bath at 85° C. for 1 hour.

[0032] (3) The sample obtained by the reaction was taken out from the three-neck round bottom flask, washed 3 times with distilled water, and then filtered and dried with a vacuum pump. The dried sample was placed in an oven at 105°C for 5 hours, taken out and ground to a size below 1mm to obtain a modified peanut shell cationic adsorbent.

Embodiment 2

[0034] The operation steps are the same as in Example 1, except that the steps (1) and (2) are respectively stirred and reacted in a constant temperature water bath at 80°C for 70 minutes.

Embodiment 3

[0036] (1) Peanut shells are crushed to a powder below 1mm by a grinding mill, weigh 4g of crushed peanut shells into a three-neck round-bottomed flask, add 15mL epichlorohydrin and 15mL DMF, and place in a constant temperature water bath at 80°C to stir and react 1 hour.

[0037] (2) 6 mL of triethylenetetramine was added dropwise to the reactant in step (1), and stirred and reacted in a constant temperature water bath at 85° C. for 1 hour.

[0038] Step (3) is the same as in Example 1.

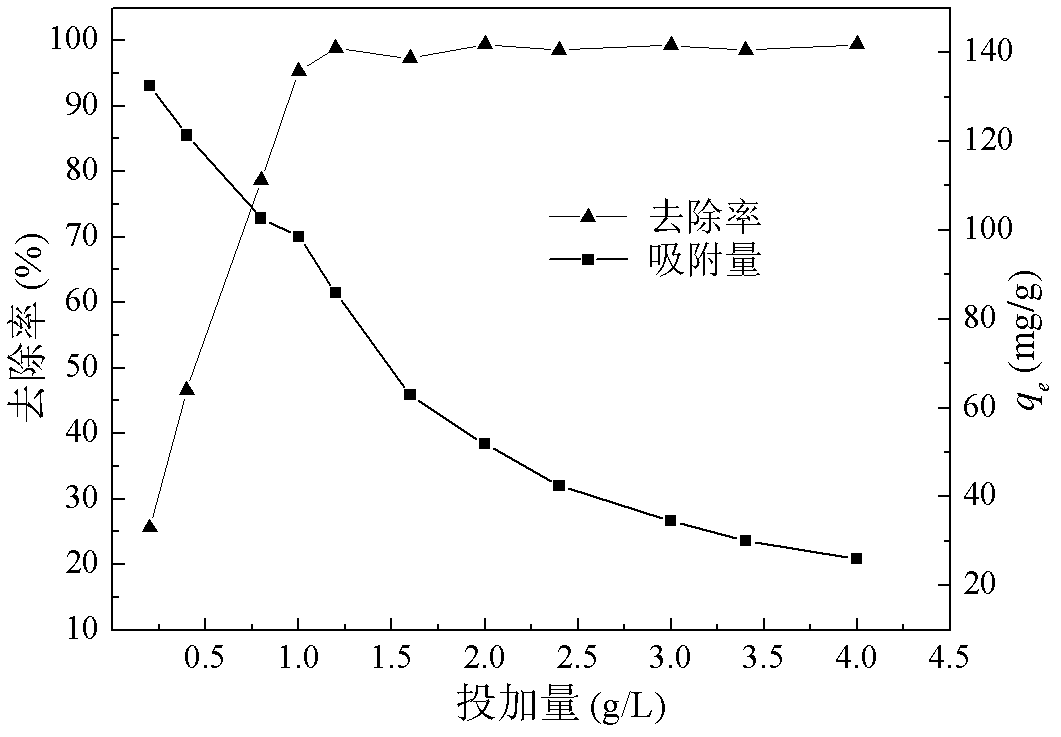

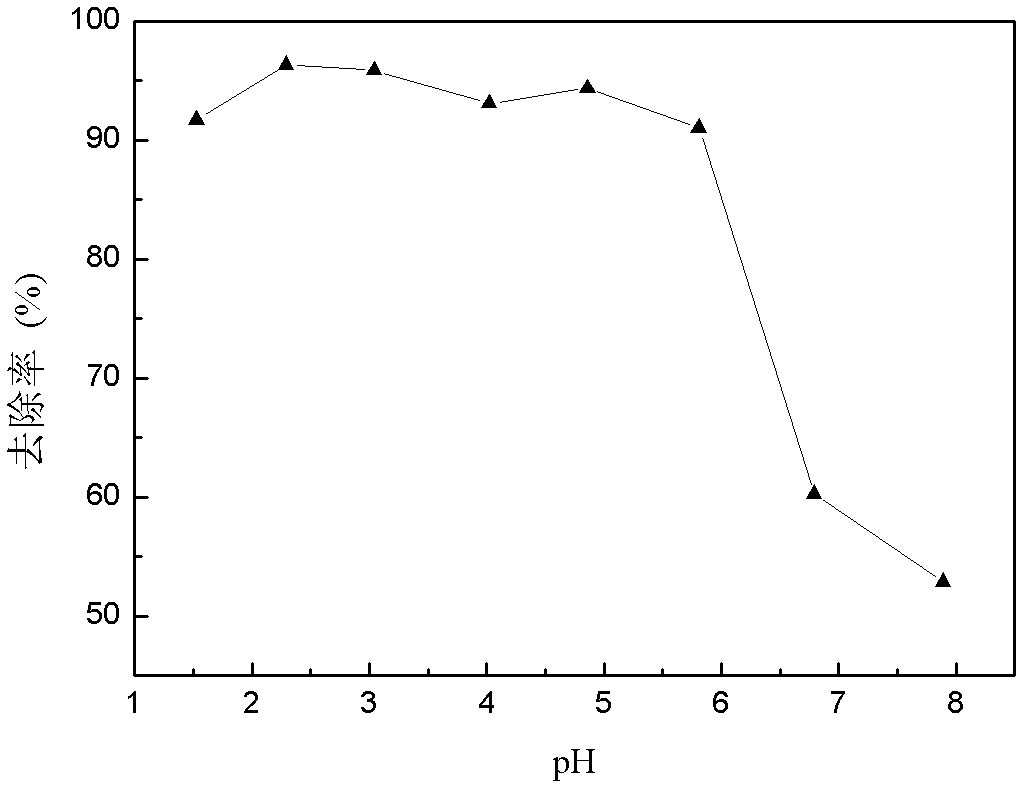

[0039] The following is an application example of using the modified peanut shell cationic adsorbent of Examples 1-3 for the adsorption of Cr(VI) ions in wastewater. The adsorption test conditions are as follows:

[0040] The dosage of modified peanut shell cationic adsorbent is 1g / L, the pH value of the solution is under the condition of natural preparation, the Cr(VI) ion concentration in the wastewater is 100mg / L, and the modified peanut shell cationic adsorbent is added to the wastewat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com