Waterproof composite regenerative road graded broken stone hardcore material and graded broken stone hardcore

A technology of graded crushed stone and composite regeneration, which is applied in roads, roads, buildings, etc., can solve problems such as unsatisfactory adaptability, and achieve the effects of reducing construction funds, controllable pollution performance, and small environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Raw materials

[0041] Sintering red mud: no more than 0.075mm;

[0042] Asphalt milling material: (0-4.75mm) files;

[0043] Water stable milling material: (4.75mm-10mm) file and (10mm-30mm) file combination.

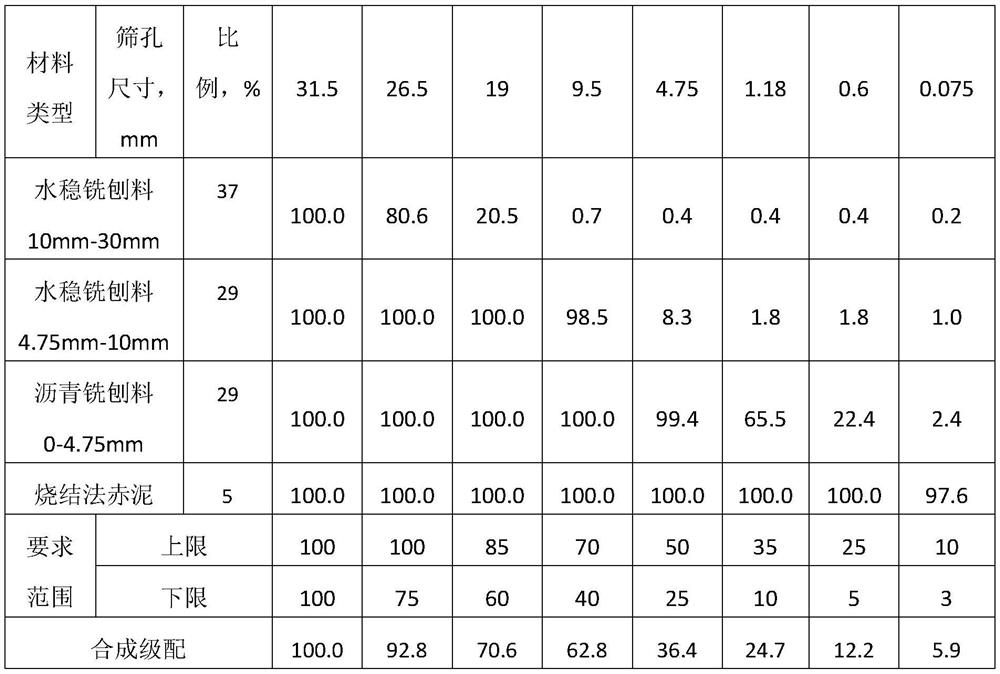

[0044] Gravel cushion material gradation control is as follows:

[0045]

[0046] Among them, the mass ratio of water-stabilized milling material (10mm-30mm): water-stabilizing milling material (5mm-10mm): asphalt milling material (0-4.75mm): sintering red mud is 37:29:29:5.

[0047] 2. Paving test

[0048] According to the frost resistance design of the road in the test area, a single layer can meet the freezing depth requirement. Lay a layer of composite recycled graded gravel cushion with a thickness of 20cm on the rolled subgrade. After the cushion pavement is completed, the measured result of the subgrade rebound modulus on the road surface is 230MPa, which meets the requirement of not less than 150MPa.

Embodiment 2

[0050] 1. Raw materials

[0051] Sintering red mud: no more than 0.075mm;

[0052] Asphalt milling material: (0-4.75mm) files;

[0053] Water stabilized milling material: (4.75mm-10mm) file, (10mm-30mm) file combination.

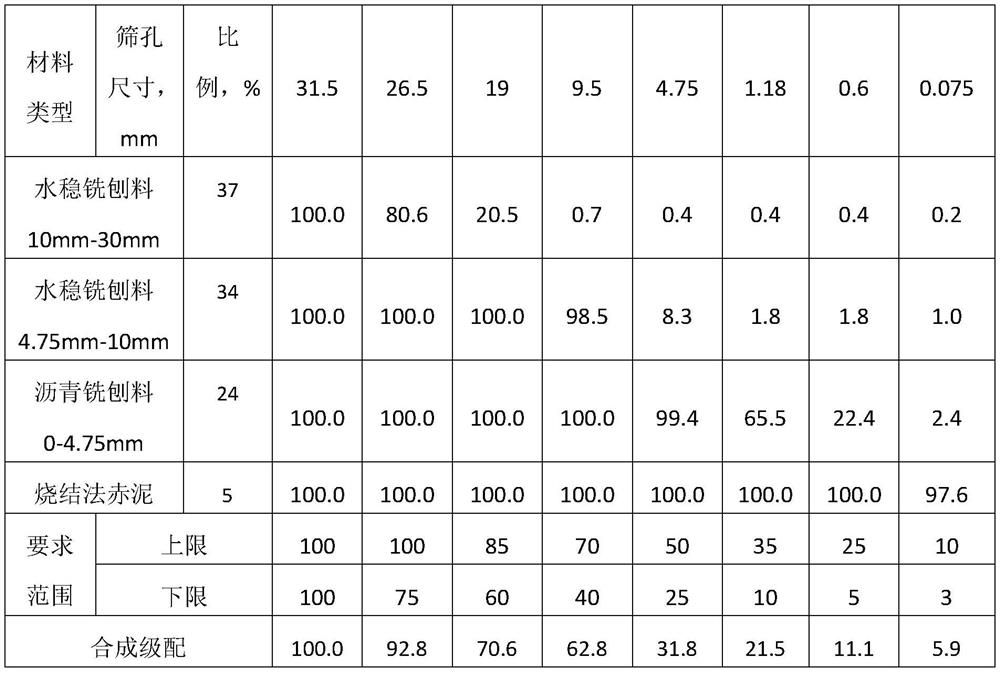

[0054] Gravel cushion material gradation control is as follows:

[0055]

[0056] Among them, the mass ratio of water-stabilized milling material (10mm-30mm): water-stabilizing milling material (4.75mm-10mm): asphalt milling material (0-4.75mm): sintering red mud is 37:34:24:5 .

[0057] 2. Paving test

[0058] The paving test method is the same as in Example 1. After the cushion pavement is completed, the measured result of the subgrade rebound modulus on the road surface is 214MPa, which meets the requirement of not less than 150MPa.

Embodiment 3

[0060] 1. Raw materials

[0061] Sintering red mud: no more than 0.075mm;

[0062] Water stabilized milling material: (0-4.75mm) files;

[0063] Water stable milling material: (4.75mm-15mm) file and (15mm-30mm) file combination.

[0064] Gravel cushion material gradation control is as follows:

[0065]

[0066]

[0067] Among them, the mass ratio of water-stabilized milling material (10mm-30mm): water-stabilized milling material (4.75mm-10mm): water-stabilized milling material (0-4.75mm): sintering red mud is 37:29:29: 5.

[0068] 2. Paving test

[0069] The paving test method is the same as in Example 1. After the cushion pavement is completed, the measured result of the subgrade rebound modulus on the road surface is 191MPa, which meets the requirement of not less than 150MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com