Waterproof heat insulation structure for steel-structure roof

A technology of steel structure and thermal insulation layer, applied in the direction of roof, roof covering, roof using flat/curved panels, etc., can solve the problem of no anti-cold bridge, unable to meet production requirements, roof condensed water hindering production, etc. To achieve the effect of good waterproof performance, prevent condensation water, and avoid cold bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

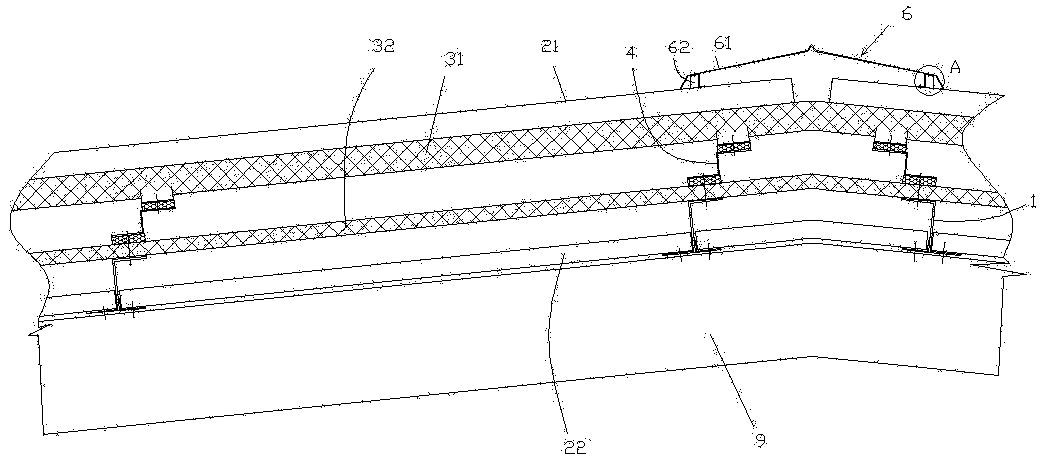

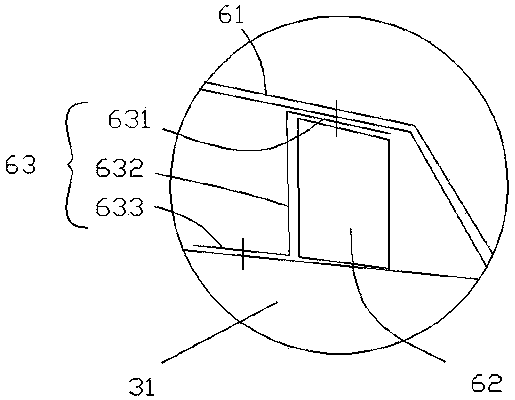

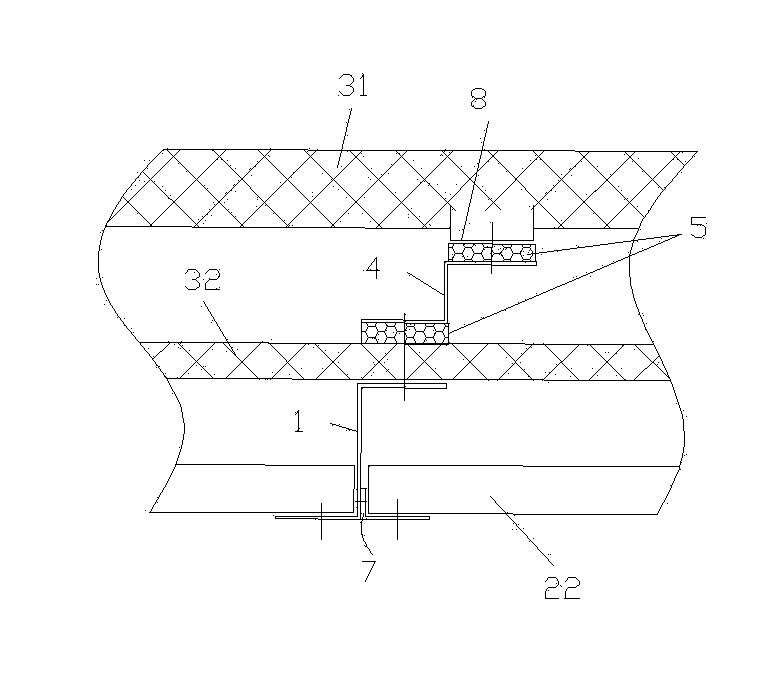

[0023] Example 1: Such as figure 1 As shown, a steel structure roof waterproof and thermal insulation structure, the roof is sloped. The steel structure is mainly composed of steel beam 9 and purlin 1. The upper end of the purlin 1 is laid with a roof top plate 21, and the lower end of the purlin 1 is a roof bottom plate 22. Two insulation layers are provided between the roof top plate 21 and the purlin 1, which are an upper insulation layer 31 and a lower insulation layer 32, respectively. The upper insulation layer 31 and the lower insulation layer 32 are separated by a supporting inner purlin 4. The supporting inner purlin 4 and the purlin 1 are arranged correspondingly, and the purlin 1 is used as the supporting base. The supporting inner purlin 4 separates the upper thermal insulation layer 31 and the lower thermal insulation layer 32 to form a closed thermal insulation cavity to prevent the "cold bridge" phenomenon. From top to bottom, a layered structure of the roof t...

Embodiment 2

[0028] Embodiment 2: The difference from Embodiment 1 is that the upper insulation layer 31 is a glass wool board layer with a thickness of 80 mm, and the lower insulation layer 32 is a glass wool board layer with a thickness of 50 mm. The insulating cushion layer 5 is a polystyrene board layer with a thickness of 20 mm.

Embodiment 3

[0029] Embodiment 3: The difference from Embodiment 1 is that the upper insulation layer 31 is a glass wool board layer with a thickness of 100 mm, and the lower insulation layer 32 is a glass wool board layer with a thickness of 30 mm. The insulating cushion layer 5 is a polystyrene board layer with a thickness of 30 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com