Polyvinyl chloride reinforcement pipe structure

A polyvinyl chloride and reinforced pipe technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of high cost, high transportation cost, heavy weight, etc., to improve the strength and pressure resistance, the overall structure is strengthened and strengthened The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

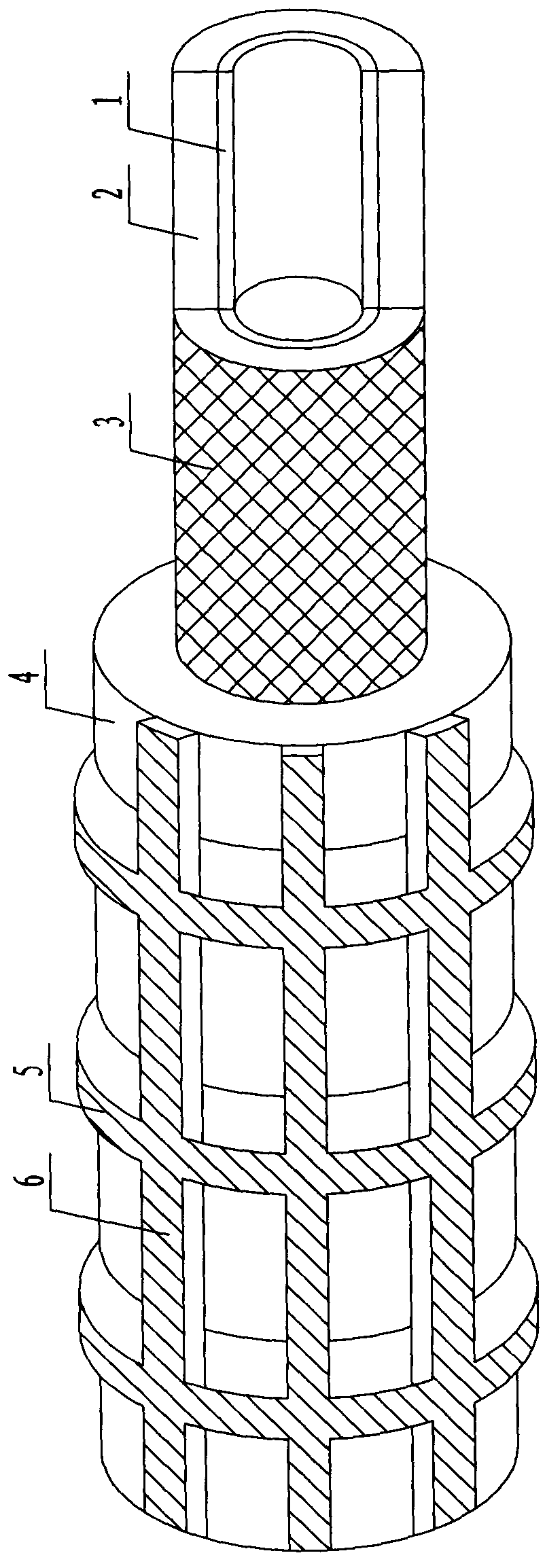

[0010] Such as figure 1 As shown, the polyvinyl chloride reinforced pipe structure includes: a scratch-resistant film layer 1, a polyvinyl chloride inner layer 2 arranged outside the scratch-resistant film layer 1, a braided reinforcement layer 3 arranged outside the polyvinyl chloride inner layer 2, The polyvinyl chloride outer layer 4 arranged on the outer side of the braided reinforcement layer 3 is uniformly interlaced on the outer side of the polyvinyl chloride outer layer 4 with a number of radially extending annular polyvinyl chloride reinforcing ribs 5 and axially extending Horizontal polyvinyl chloride reinforcement 6.

[0011] Such as figure 1 As shown, in this example, in order to achieve a better reinforcement effect, the braid reinforcement layer 3 is a polymer plastic fiber wire or a helical metal wire....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com