Crude oil conveying pipeline system and crude oil conveying method thereof

A technology for transporting pipelines and crude oil, which is applied in the crude oil transportation pipeline system and its field of crude oil transportation. It can solve the problems of lower crude oil temperature, large transportation energy consumption, and increased crude oil viscosity, so as to reduce transportation resistance, avoid direct contact, and reduce transportation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

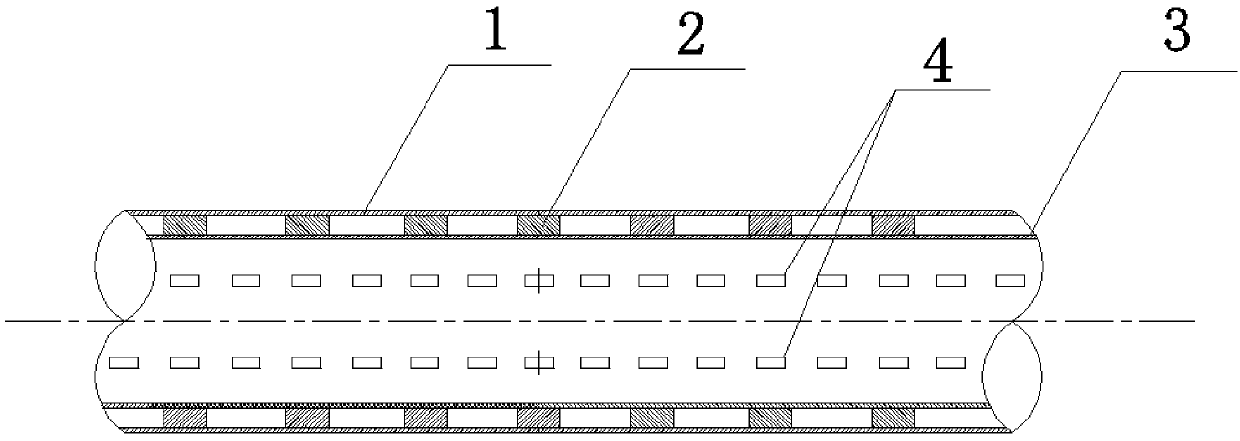

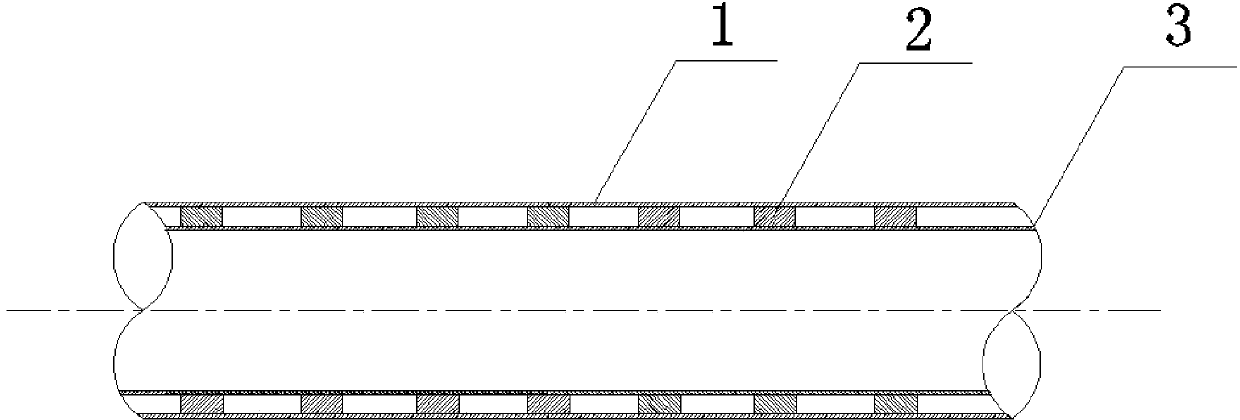

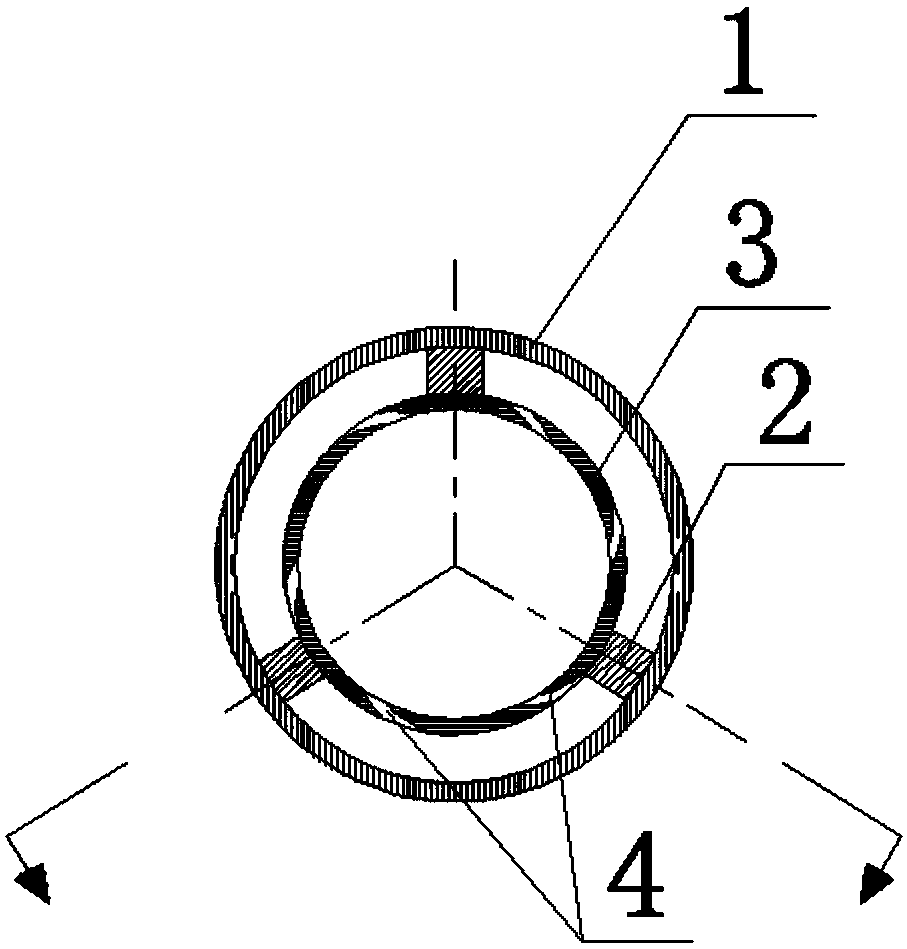

[0025] A crude oil transportation pipeline system, comprising an outer pipe 1 and an inner pipe 3, the inner pipe 3 is set inside the outer pipe 1, the inner pipe 3 is filled with crude oil, and a positioning block 2 is installed between the inner pipe 3 and the outer pipe 1, A closed cavity is formed between the inner tube 3 and the outer tube 1, and the high-pressure liquid filled in the cavity is a low-viscosity liquid that is easily obtained such as condensate oil or light oil or oilfield production water, and the pressure is 0.5MPa-15MPa.

[0026] There are a plurality of swirl holes 4 on the inner pipe wall from the outer surface to the inner surface. The swirl holes 4 are evenly distributed on the inner pipe wall. The ratio of the diameter of the swirl holes to the diameter of the inner pipe is 0.001-0.02, so as to form a uniform conveying medium layer. The swirl holes obliquely intersect with the inner pipe wall, and the included angles formed by each swirl hole and th...

Embodiment 2

[0033] A crude oil transportation pipeline system, including an outer pipe and an inner pipe, the inner pipe is set inside the outer pipe, the inner pipe is filled with crude oil, a positioning block is installed between the inner pipe and the outer pipe, and the inner pipe and the outer pipe form a The airtight cavity, the high-pressure gas that can also be filled in the cavity is an inert gas such as natural gas or nitrogen, and the pressure is 0.5MPa-15MPa.

[0034] There are multiple swirl holes on the inner pipe wall from the outer surface to the inner surface, and the swirl holes are evenly distributed on the inner pipe wall. The ratio of the diameter of the swirl holes to the diameter of the inner pipe is 0.001-0.02, so as to form a uniform conveying medium layer. The swirl holes obliquely intersect with the inner pipe wall, and the included angles formed by each swirl hole and the tangent plane of the swirl hole inlet are consistent. The swirl hole connects the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com