Fiber bragg grating pressure sensor used in high-temperature high-voltage environment and manufacturing method

A technology of pressure sensor and optical fiber grating, which is applied in the field of optical fiber pressure sensor, can solve the problems such as inapplicability, and achieve the effects of no electromagnetic interference and low optical transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with the accompanying drawings.

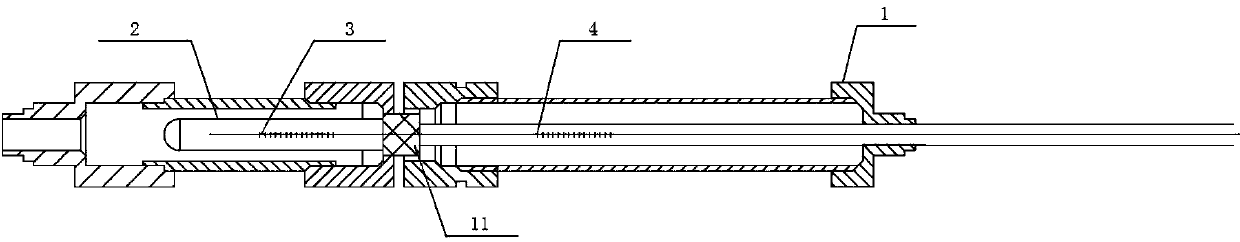

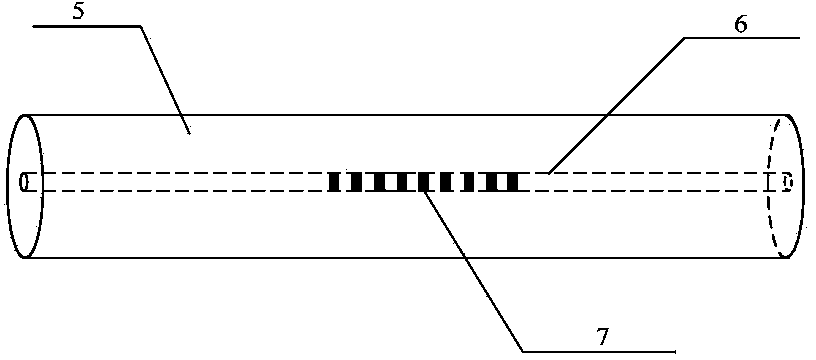

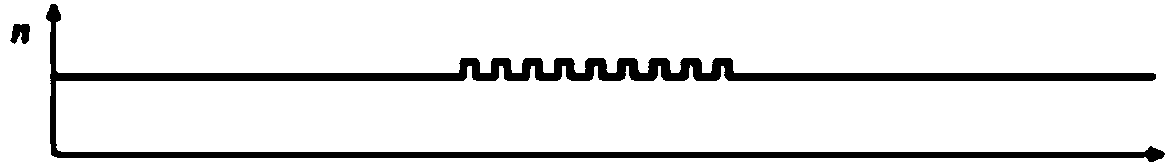

[0028] The invention discloses a fiber grating pressure sensor used in a high temperature and high pressure environment, and its preferred structure schematic diagram is as follows figure 1shown. The fiber grating pressure sensor includes a package housing 1, an elastic body 2 and a fiber grating sensing device arranged in the package housing 1, and the fiber grating sensing device includes a pressure sensitive grating 3 and a temperature compensation device connected to each other through an isolation device 11. The grating 4 , wherein the pressure sensitive grating 3 is embedded in the elastic body 2 , and the temperature compensation grating 4 is outside the elastic body 2 and packaged in the package casing 1 . Among them, the packaging shell 1 can be made of stainless steel or other rigid materials, the elastic body 2 is made of metal matrix composite material, the fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com