Fiber grating osmometer

A technology of optical fiber grating and piezometer, applied in the direction of fluid pressure measurement using optical methods, can solve problems such as difficult productization and complex structure, and achieve the effects of easy productization, high precision, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, but are only examples to make the advantages of the present invention more clear and easy to understand.

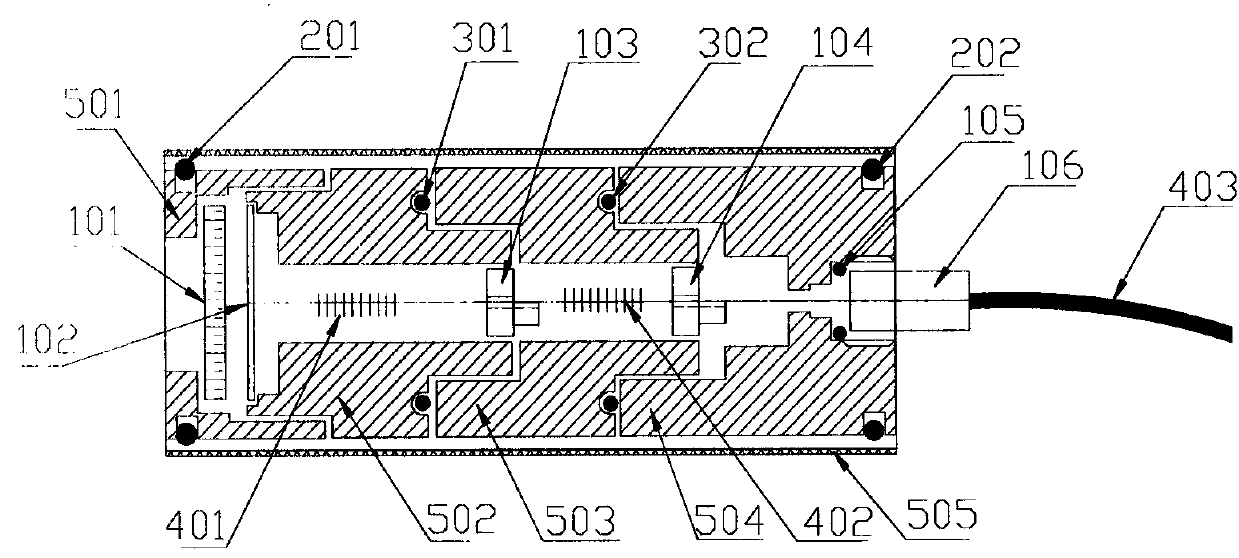

[0017] Such as figure 1 As shown, a fiber grating osmometer includes an outer cylinder 505, permeable stone bases 501 and end plugs 504 respectively arranged at both ends of the outer cylinder 505, and a temperature sensing device which is arranged in the outer cylinder 505 and is threadedly connected with the end plugs 504. The fiber grating cavity 503, the pressure-sensitive fiber grating cavity 502 set in the outer cylinder 505 and screwed to the permeable stone base 501; wherein, the permeable stone base 501 is hollow inside, and the permeable stone 101 is arranged inside, and the end plug 504 A through hole is provided, and an armored fixing structure 106 sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com