A rolling stone impact field simulation test device

A simulation test and on-site technology, which is applied in the field of rolling stone impact field simulation test devices, can solve the problems of the influence of the size of the impact force of the rolling stone, the inability to accurately test the impact force of the rolling stone, and the unclear distribution position of the force sensor, etc., and achieve the effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

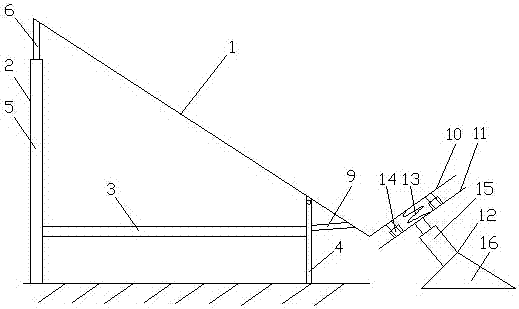

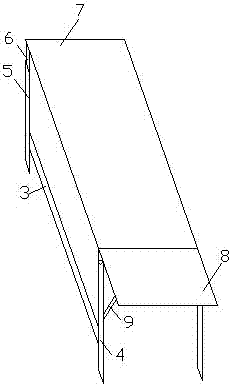

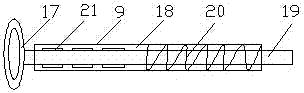

[0051] A rolling stone impact field simulation test device, including blocking parts, also includes a track part in contact with the blocking part, the track part is composed of a track 1 and a bracket, and the bracket is composed of a rear stand 2, a connecting rod 3 and a front stand 4. One end of the connecting rod 3 is connected to the rear stand 2, and the other end is connected to the front stand 4. The rear stand 2 is composed of a telescopic column 5 and a telescopic rod 6 slidingly connected in the telescopic column 5. The track 1 is composed of a rear sliding surface 7 and a front sliding surface 8, the rear end of the rear sliding surface 7 is fixedly connected with the telescopic rod 6, the front end is hinged with the front stand 4, and the rear end of the front sliding surface 8 is connected with the front stand 4. Hinged, the front end is connected with the middle part of the front stand 4 through the shrinkage part 9; the blocking part is composed of an upper ba...

Embodiment 2

[0054] A rolling stone impact field simulation test device, including blocking parts, also includes a track part in contact with the blocking part, the track part is composed of a track 1 and a bracket, and the bracket is composed of a rear stand 2, a connecting rod 3 and a front stand 4. One end of the connecting rod 3 is connected to the rear stand 2, and the other end is connected to the front stand 4. The rear stand 2 is composed of a telescopic column 5 and a telescopic rod 6 slidingly connected in the telescopic column 5. The track 1 is composed of a rear sliding surface 7 and a front sliding surface 8, the rear end of the rear sliding surface 7 is fixedly connected with the telescopic rod 6, the front end is hinged with the front stand 4, and the rear end of the front sliding surface 8 is connected with the front stand 4. Hinged, the front end is connected with the middle part of the front stand 4 through the shrinkage part 9; the blocking part is composed of an upper ba...

Embodiment 3

[0060] A rolling stone impact field simulation test device, including blocking parts, also includes a track part in contact with the blocking part, the track part is composed of a track 1 and a bracket, and the bracket is composed of a rear stand 2, a connecting rod 3 and a front stand 4. One end of the connecting rod 3 is connected to the rear stand 2, and the other end is connected to the front stand 4. The rear stand 2 is composed of a telescopic column 5 and a telescopic rod 6 slidingly connected in the telescopic column 5. The track 1 is composed of a rear sliding surface 7 and a front sliding surface 8, the rear end of the rear sliding surface 7 is fixedly connected with the telescopic rod 6, the front end is hinged with the front stand 4, and the rear end of the front sliding surface 8 is connected with the front stand 4. Hinged, the front end is connected with the middle part of the front stand 4 through the shrinkage part 9; the blocking part is composed of an upper ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com