Intelligent steel salvaging system

An intelligent, lifting mechanism technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of increasing labor intensity of workers, restricting production rhythm, and large mechanical inertia, so as to maintain long-term stable work, Reduced maintenance workload and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

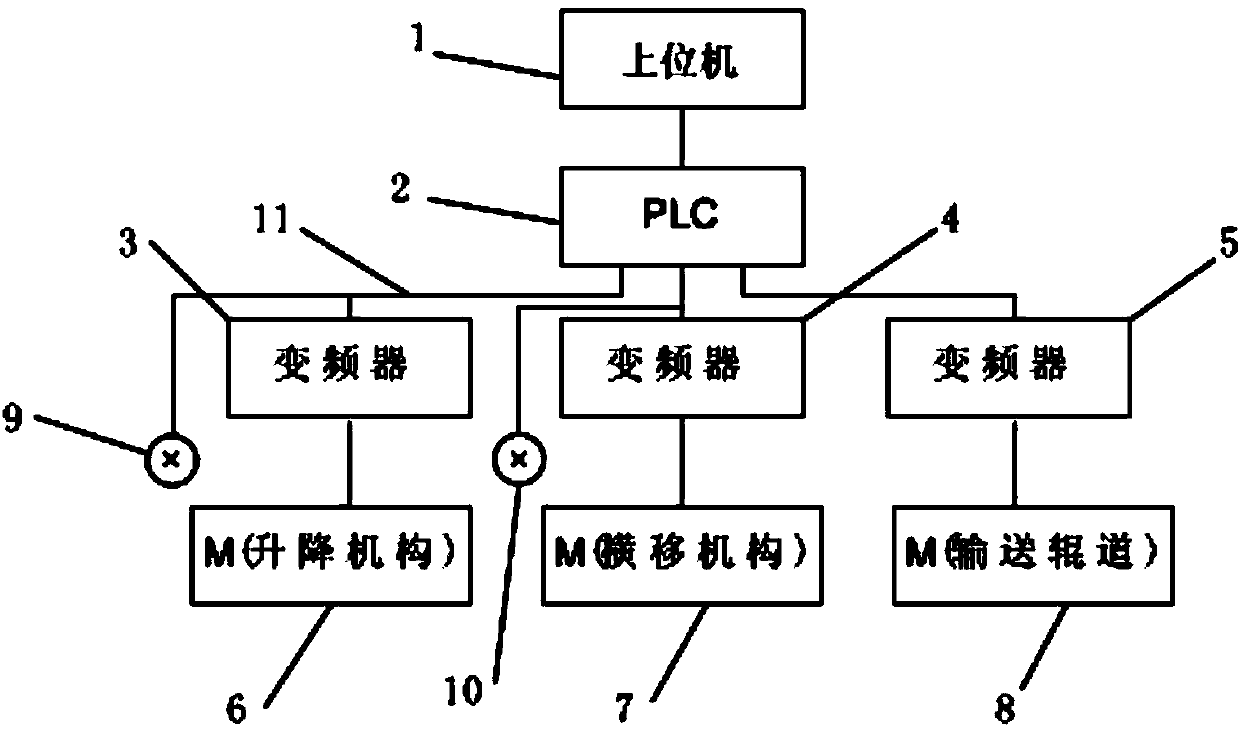

[0016] Such as figure 1 The structure shown is the intelligent steel fishing system of the present invention, which is the main control system applied to the steel billet transmission process in the production of metallurgical industry. The system includes a lifting mechanism 6, a traverse mechanism 7, a conveying roller table 8 and a logic control unit.

[0017] In order to solve the problems existing in the prior art and overcome its defects, realize the purpose of the invention of the automatic control of billet transmission, the technical scheme adopted by the present invention is as follows:

[0018] Such as figure 1 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com