AGM separator with high liquid absorption capacity and preparation method thereof

A technology with high liquid absorption and separators, which is applied in the direction of separators/films/diaphragms/spacers, electrical components, circuits, etc., can solve the problem of AGM separator imports, poor performance of AGM separators, and poor battery life and other problems, to avoid over-drying, uniform pore size, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

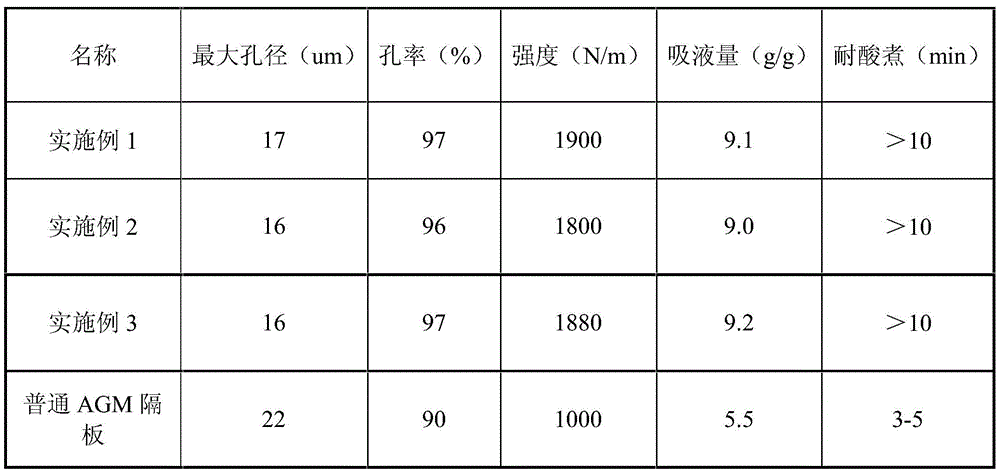

Examples

Embodiment 1

[0026] The method for preparing the AGM separator with high liquid absorption capacity in this embodiment comprises the following steps:

[0027] 1), dispersion pulping: get 85 parts of high-alkali glass fiber cottons with an average diameter of 1.1um and 15 parts of high-alkali glass fiber cottons with a diameter of 2.5um and add them into a beater for beating and disperse;

[0028] 2), mixing step 1) disperse the slurry obtained by pulping;

[0029] 3), add water to dilute the mixed slurry to a concentration of 0.3%, and perform slag removal treatment;

[0030] 4), the step 3) diluted slurry is sent to the forming device to form a wet partition;

[0031] 5), suction dehydration: make the wet cardboard in step 4) sequentially pass through multi-stage vacuum suction devices for suction dehydration, so that the moisture content of the wet partition is lower than 35% (about 30% in this embodiment);

[0032] 6) Drying at low temperature: drying the wet cardboard dehydrated in s...

Embodiment 2

[0039] The method for preparing the AGM separator with high liquid absorption capacity in this embodiment comprises the following steps:

[0040] 1), dispersion pulping: get 80 parts of high-alkali glass fiber cottons with a diameter of 1.5um and 20 parts of high-alkali glass fiber cottons with a diameter of 3um and add them into a beater for beating and disperse;

[0041] 2), mixing step 1) disperse the slurry obtained by pulping;

[0042] 3), adding water to dilute the mixed slurry to a concentration of 0.5% and performing slag removal;

[0043] 4), the step 3) diluted slurry is sent to the forming device to form a wet partition;

[0044] 5), suction dehydration: make the wet paperboard in step 4) sequentially pass through multi-stage vacuum suction devices for suction dehydration, so that the moisture content of the wet partition is about 33%;

[0045] 6) Drying at low temperature: drying the wet cardboard dehydrated in step 5) at 120-150°C.

[0046] In this example:

...

Embodiment 3

[0052] This embodiment prepares the method for preparing AGM separator with high liquid absorption capacity, comprising the following steps:

[0053] 1), dispersion pulping: get 90 parts of high-alkali glass fiber cotton with a diameter of 0.8um and 10 parts of high-alkali glass fiber cotton with a diameter of 2um and add them to a beater for beating and disperse;

[0054] 2), mixing step 1) disperse the slurry obtained by pulping;

[0055] 3), add water to dilute the mixed slurry to a concentration of 0.2%, and perform slag removal treatment;

[0056] 4), the step 3) diluted slurry is sent to the forming device to form a wet partition;

[0057]5), suction dehydration: make the wet cardboard in step 4) go through multi-stage vacuum suction device successively for suction dehydration, so that the moisture content of the wet partition is about 28%;

[0058] 6) Drying at low temperature: drying the wet cardboard dehydrated in step 5) at 120-150°C.

[0059] In this example:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com